Need help finding what you are looking for?

Contact Us

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1636443

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1636443

India Electric Vehicle Battery Separator - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

PUBLISHED:

PAGES: 95 Pages

DELIVERY TIME: 2-3 business days

SELECT AN OPTION

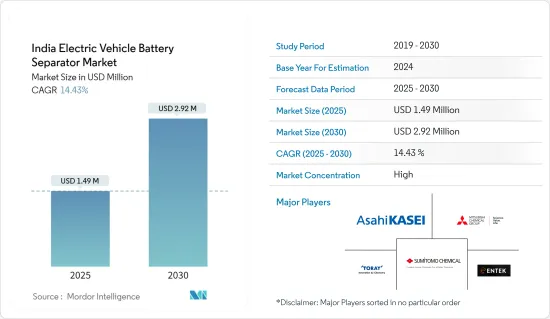

The India Electric Vehicle Battery Separator Market size is estimated at USD 1.49 million in 2025, and is expected to reach USD 2.92 million by 2030, at a CAGR of 14.43% during the forecast period (2025-2030).

Key Highlights

- Over the medium term, factors such as the increasing demand for electric vehicles and supportive government initiatives are expected to drive the market during the forecast period.

- On the other hand, limited domestic company participation is likely to hinder market growth during the forecast period.

- Nevertheless, technological innovations and the development of sustainable materials are expected to provide significant opportunities for the market in the coming years.

India Electric Vehicle Battery Separator Market Trends

Increasing Demand for Electric Vehicles

- India ranks among the world's top five CO2 emitters. In response to the pressing issue of air pollution, the Indian government is actively promoting policies to boost the number of electric vehicles (EVs) on the roads. The Society of Manufacturers of Electric Vehicles (SMEV) reported that India achieved sales of 1.67 million EVs in 2023.

- Entities looking to establish charging stations have received clarity from the government: licensing from the ministry may not be necessary. Furthermore, the government has set an ambitious goal: by 2030, all new vehicle sales will be fully electric.

- By 2030, the Indian government aims for electric vehicles to make up 30% of private car sales, 70% of commercial vehicle sales, and a remarkable 80% of sales for two-and three-wheelers. These ambitious targets are poised to boost the demand for batteries in India and heightened the need for high-quality battery separators, which are crucial for ensuring battery efficiency and longevity.

- In April 2019, India rolled out the second phase of its "Faster Adoption and Manufacturing of Electric Vehicles in India" (FAME India) scheme. This initiative aims to lower the purchase price of hybrid and electric vehicles, particularly focusing on public transportation (like buses, rickshaws, and taxis) and private two-wheelers.

- In February 2024, the government announced a boost in investment for the FAME II scheme, raising it from INR 10,000 crore (USD 1206.5 million) to INR 11,500 crore (USD 1387.4 million). This scheme not only focuses on enhancing the adoption of electric vehicles but also emphasizes the establishment of essential charging infrastructure. Additionally, the government has upped the subsidy incentives from Rs 10,000 per kWh to Rs 15,000 per kWh. Such measures are anticipated to significantly bolster the adoption of electric vehicles in India, subsequently driving up the demand for lithium-ion batteries.

- In light of this surging demand, battery manufacturers are proactively setting up facilities for battery component production. For example, in February 2024, Himadri Speciality Chemicals, an Indian firm, unveiled plans for a lithium-ion battery component manufacturing facility, boasting a capacity of 2 lakh tonnes per annum. The project, estimated at INR 4,800 crore (USD 579.1 million), is set to unfold over approximately six years.

- Given the dynamic evolution of the EV industry, with its strong focus on innovation and performance, battery separators are emerging as pivotal players, propelling market growth in India. As the EV market continues its upward trajectory, the demand for these vital battery components is set to surge.

Lithium-Ion Batteries Segment to Dominate the Market

- Traditionally, lithium-ion batteries powered consumer electronics like mobile phones and PCs. However, their role has evolved, becoming the preferred power source for hybrid and fully electric vehicles (EVs). This shift is largely attributed to the environmental benefits of EVs, which produce no CO2, nitrogen oxides, or other greenhouse gases.

- Lithium-ion batteries are outpacing other battery types in popularity, thanks to their favorable capacity-to-weight ratio. Their adoption is further fueled by superior performance, extended shelf life, and plummeting prices. With high energy density and long cycle life, lithium-ion batteries have become the go-to choice for EV manufacturers. As India spearheads the global EV market, the demand for lithium-ion batteries-and by extension, battery separators-is on the rise.

- A major factor bolstering this trend is the consistent drop in lithium-ion battery prices. Over the last decade, technological advancements, economies of scale, and refined manufacturing processes have driven down costs.

- On a global scale, lithium-ion battery prices have seen a dramatic decline over the past decade. In 2023, an average lithium-ion battery was priced at approximately USD 139 per kWh, marking an impressive 82% drop from 2013 levels.

- Looking ahead, BloombergNEF projects a renewed decline in battery costs starting 2025. This is attributed to the activation of new extraction and refinery capacities, leading to a softening of lithium prices. Their 2023 Battery Price Survey forecasts the average pack price to dip below USD 113/kWh by 2025 and further down to USD 80/kWh by 2030.

- This price reduction has made electric vehicles more budget-friendly, spurring their widespread adoption in India. With a growing number of consumers and businesses embracing EVs, the surge in lithium-ion battery production and demand has further bolstered the market for battery separators.

- Consequently, lithium-ion batteries remain central to India's EV battery landscape, propelling the demand for cutting-edge separators and solidifying their dominant market position.

India Electric Vehicle Battery Separator Industry Overview

The Indian electric vehicle battery separator market is semi-consolidated. Some of the major players (not in particular order) include Sumitomo Chemical Co., Ltd., Mitsubishi Chemical Group Corporation, Asahi Kasei Corporation, Toray Industries, Inc., and Entek International LLC among others.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

Product Code: 50003710

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Scope of Study

- 1.2 Market Definition

- 1.3 Study Assumptions

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET OVERVIEW

- 4.1 Introduction

- 4.2 Market Size and Demand Forecast in USD billion, till 2029

- 4.3 Recent Trends and Developments

- 4.4 Government Policies and Regulations

- 4.5 Market Dynamics

- 4.5.1 Drivers

- 4.5.1.1 Increasing Demand of Electric Vehicles

- 4.5.1.2 Supportive Government Initiatives

- 4.5.2 Restraints

- 4.5.2.1 Limited Company Participation

- 4.5.1 Drivers

- 4.6 Supply Chain Analysis

- 4.7 PESTLE Analysis

- 4.8 Investment Analysis

5 MARKET SEGMENTATION

- 5.1 Battery Type

- 5.1.1 Lithium-Ion Batteries

- 5.1.2 Lead-Acid Batteries

- 5.1.3 Others

- 5.2 Material Type

- 5.2.1 Polypropylene

- 5.2.2 Polyethylene

- 5.2.3 Other Material Types

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Strategies Adopted by Leading Players

- 6.3 Company Profiles

- 6.3.1 Sumitomo Chemical Co., Ltd.

- 6.3.2 Asahi Kasei Corporation

- 6.3.3 Mitsubishi Chemical Group Corporation

- 6.3.4 Entek International

- 6.3.5 Toray Industries Inc.

- 6.3.6 24M Technologies

- 6.3.7 Celgard LLC

- 6.3.8 SK Innovation Co. Ltd

- 6.3.9 UBE Corp

- 6.3.10 LG Chem Ltd.

- 6.4 List of Other Prominent Companies

- 6.5 Market Ranking/Share Analysis

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Expansion in Emerging Battery Materials

Have a question?

SELECT AN OPTION

Have a question?

Questions? Please give us a call or visit the contact form.