Need help finding what you are looking for?

Contact Us

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1636464

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1636464

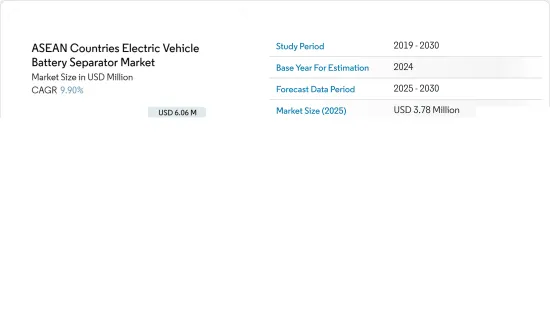

ASEAN Countries Electric Vehicle Battery Separator - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

PUBLISHED:

PAGES: 110 Pages

DELIVERY TIME: 2-3 business days

SELECT AN OPTION

The ASEAN Countries Electric Vehicle Battery Separator Market size is estimated at USD 3.78 million in 2025, and is expected to reach USD 6.06 million by 2030, at a CAGR of 9.9% during the forecast period (2025-2030).

Key Highlights

- Over the medium period, the growing adoption of electric vehicles and the decreasing price of lithium-ion batteries is expected to drive the market in the forecast period.

- On the other hand, the supply chain gap in battery materials created by the monopolies of some countries, such as ingredient shortages or distribution bottlenecks, is expected to restrain market growth in the future.

- Nevertheless, the increasing research and development of other battery chemistries like solid-state batteries, advanced lithium-ion chemistry, Sodium-ion batteries, etc, are expected to create an opportunity for the market in the future.

- Thailand is anticipated to witness significant growth in the ASEAN countries' electric vehicle battery separation market due to the rising adoption of EVs across the region.

ASEAN Countries Electric Vehicle Battery Separator Market Trends

Lithium-Ion Battery Type to Dominate the Market

- Li-ion batteries, known for their high energy density, long cycle life, and low self-discharge rate, are the preferred choice for electric vehicles (EVs). This dominant preference not only propels the growth of the EV battery separator market but also shapes the broader trajectory of the EV industry.

- Key market players are boosting their R&D investments and production capabilities, intensifying competition and driving prices down. Bloomberg NEF highlights that while average battery pack prices for EVs and battery energy storage systems (BESS) have generally risen, 2023 marked a significant 13% drop, bringing prices down to USD 139/kWh. Projections suggest this decline will persist, with prices anticipated to reach USD 113/kWh by 2025 and plummet further to USD 80/kWh by 2030, driven by relentless technological and manufacturing advancements.

- ASEAN nations, including Thailand, the Philippines, Malaysia, Indonesia, and Vietnam, are emerging as key players in the global lithium-ion battery supply chain. Their strategic locations, government incentives, and abundant natural resources have successfully attracted investments into battery manufacturing.

- In July 2024, Indonesia launched its first-ever EV battery plant. As Southeast Asia's largest economy and the custodian of the world's most extensive nickel reserves, Indonesia is carving out a significant role in the global electric vehicle supply chain. This plant, a joint venture between South Korean titans LG Energy Solution (LGES) and Hyundai Motor Group, boasts a robust annual capacity of 10 Gigawatt hours (GWh) for battery cell production. Such initiatives are poised to bolster lithium-ion battery production in the region in the coming years.

- Moreover, advancements in lithium-ion battery technology, such as heightened energy density, improved safety features, and accelerated charging, are spurring the development of innovative separator materials. These separators, crucial for meeting the energy and thermal demands of Li-ion batteries, play a vital role in ensuring safety and reliability, thereby driving innovation and demand in the separator market.

- In June 2023, ProLogium unveiled a groundbreaking battery architecture, marking a significant evolution in three decades of lithium-ion technology. By substituting the traditional polymer separator film with a ceramic alternative, ProLogium has set a new standard in the lithium-ion battery sector for electric vehicles. Such innovations are poised to amplify the demand for advanced lithium battery separators in the region.

- Given these developments, the production of lithium-ion batteries is set to surge, leading to a substantial increase in the capacity of EV battery separators during the forecast period.

Thailand to Witness Significant Growth

- Thailand, with its robust automotive industry, strategic positioning, and government support, has emerged as the top producer of EV battery separators in the ASEAN region. As the country shifts towards clean energy and embraces electric vehicles, companies are sharpening their focus on this crucial segment. Rising consumer interest is driven by increased environmental awareness, the economic advantages of EV ownership, and swift technological progress in the industry.

- Recently, electric vehicle (EV) sales have surged in the ASEAN region. For instance, the Thailand Automotive Institute reported that in 2023, registered battery electric vehicles (BEVs) reached 76.36 thousand units, marking a 6.89-fold increase from 2022 and a staggering 47.6-fold jump since 2019. With EV sales, including BEVs, projected to rise, the demand for batteries and battery separators in the region is set to amplify.

- Additionally, battery separators in the region are navigating challenges like falling lithium-ion battery prices, escalating demand, and the crucial need for safety and efficiency in EV applications. Recently, leading global companies have invested in projects to enhance lithium-ion battery production for EVs in the region.

- For example, in February 2024, BMW announced a new battery factory for electric vehicles in Rayong, Thailand. This initiative is expected to strengthen the country's battery supply chains. BMW sees Thailand as a key export center for its EV batteries, aiming at the larger Asia Pacific market. Such moves are likely to boost battery production in Thailand and heighten the demand for lithium-ion battery separators in the coming years.

- Furthermore, Thailand's automotive industry is ramping up the production of innovative electric vehicle (EV) models. As global leaders pivot to include EV manufacturing, there's a notable surge in demand for premium battery components, especially separators. This trend highlights the industry's commitment to innovation and sustainability.

- For instance, in August 2024, Omoda and Jaecoo Thailand, a branch of the Chinese automaker Chery Automobile, strengthened their presence in Thailand by launching two electric vehicle (EV) models. The debut included two versions for each model: the compact SUV Omoda C5 EV and the rugged off-road SUV Jaecoo 6 EV, making its global debut in a right-hand drive variant. Such initiatives are expanding their electric vehicle offerings in the region, fueling the growth of the EV battery separator market.

- Consequently, these projects and initiatives are poised to boost EV demand and substantially elevate the need for EV battery separators in the coming years.

ASEAN Countries Electric Vehicle Battery Separator Industry Overview

ASEAN Countries' electric vehicle battery separator market is semi-fragmented. Some key players (not in particular order) are Mitsubishi Chemical Group Corporation, Hitachi Chemical Company Ltd, Toray Industries Inc., Sumitomo Chemical Co. Ltd, Teijin Ltd, among others.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

Product Code: 50003731

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Scope of the Study

- 1.2 Market Definition

- 1.3 Study Assumptions

2 EXECUTIVE SUMMARY

3 RESEARCH METHODOLOGY

4 MARKET OVERVIEW

- 4.1 Introduction

- 4.2 Market Size and Demand Forecast in USD, till 2029

- 4.3 Recent Trends and Developments

- 4.4 Government Policies and Regulations

- 4.5 Market Dynamics

- 4.5.1 Drivers

- 4.5.1.1 Growing Adoption of Electric Vehicles

- 4.5.1.2 Decline in cost of battery raw materials

- 4.5.2 Restraints

- 4.5.2.1 The Supply Chain Gap

- 4.5.1 Drivers

- 4.6 Supply Chain Analysis

- 4.7 Industry Attractiveness - Porter's Five Forces Analysis

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Consumers

- 4.7.3 Threat of New Entrants

- 4.7.4 Threat of Substitutes Products and Services

- 4.7.5 Intensity of Competitive Rivalry

- 4.8 Investment Analysis

5 MARKET SEGMENTATION

- 5.1 Battery

- 5.1.1 Lithium-ion

- 5.1.2 Lead-Acid

- 5.1.3 Others

- 5.2 Material Type

- 5.2.1 Polypropylene

- 5.2.2 Polyethylene

- 5.2.3 Other Material Types

- 5.3 Geography

- 5.3.1 Indonesia

- 5.3.2 Vietnam

- 5.3.3 Thailand

- 5.3.4 Myanmar

- 5.3.5 Philippines

- 5.3.6 Rest of ASEAN Countries

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Strategies Adopted by Leading Players

- 6.3 Company Profiles

- 6.3.1 Mitsubishi Chemical Group Corporation

- 6.3.2 Hitachi Chemical Company Ltd

- 6.3.3 Toray Industries Inc.

- 6.3.4 Sumitomo Chemical Co. Ltd

- 6.3.5 Teijin Ltd

- 6.3.6 SK Nexilis

- 6.3.7 Asahi Kasei

- 6.3.8 W-Scope Corporation

- 6.3.9 Southeast Asia Manufacturing Co., Ltd

- 6.4 List of Other Prominent Companies

- 6.5 Market Ranking Analysis

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Increasing Research and Development of Other Battery Chemistries

Have a question?

SELECT AN OPTION

Have a question?

Questions? Please give us a call or visit the contact form.