Need help finding what you are looking for?

Contact Us

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1636270

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1636270

North America Electric Vehicle Battery Materials - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

PUBLISHED:

PAGES: 110 Pages

DELIVERY TIME: 2-3 business days

SELECT AN OPTION

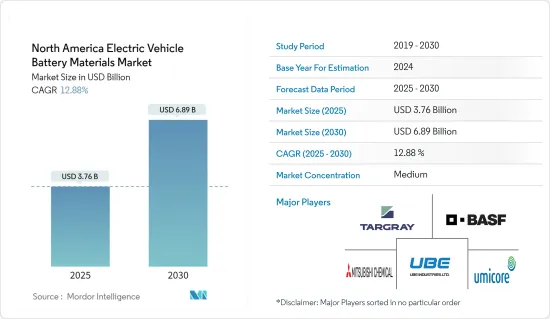

The North America Electric Vehicle Battery Materials Market size is estimated at USD 3.76 billion in 2025, and is expected to reach USD 6.89 billion by 2030, at a CAGR of 12.88% during the forecast period (2025-2030).

Key Highlights

- In the coming years, the North America Electric Vehicle Battery Materials Market is poised to be significantly driven by surging electric vehicle sales and bolstering government policies and regulations.

- Conversely, the North America Electric Vehicle Battery Materials Market faces challenges due to a heavy dependence on imports, stemming from insufficient domestic raw material production.

- Nevertheless, continued efforts are being made to develop advanced battery technology. This factor is expected to create several opportunities for the market in the future.

- With a robust vehicle manufacturing and sales industry, the United States is set to dominate the growth landscape, likely registering the highest expansion during the forecast period.

North America Electric Vehicle Battery Materials Market Trends

Lithium-ion Batteries to Dominate the Market

- The lithium-ion battery segment is a cornerstone of the North American electric vehicle (EV) battery materials market, characterized by its pivotal role in the growth and advancement of electric vehicle technology. As the most widely adopted battery type for electric vehicles, lithium-ion batteries offer a favorable combination of energy density, efficiency, and longevity, making them indispensable for modern EV applications.

- Significant advancements in battery technology and manufacturing processes over the last decade have propelled the adoption of lithium-ion batteries in the electric vehicle market. These strides have not only slashed costs but also bolstered performance and reliability, rendering lithium-ion batteries increasingly attractive to manufacturers and consumers alike.

- In recent years, the price of lithium-ion batteries and cell packs has been on the decline, making them more attractive to end-user industries. After experiencing slight price hikes in 2022, battery prices were once again declining in 2023. The cost of lithium-ion battery packs has decreased by 14% to reach a historic low of USD 139/kWh.

- This segment encompasses a diverse array of materials, each contributing to the overall performance and functionality of the batteries. These materials are chosen for their ability to enhance the battery's energy density, cycle life, and thermal stability, thereby addressing critical performance parameters required by the automotive industry. Nickel-rich cathode materials, for instance, are particularly favored for their high energy capacity, which directly translates to extended driving ranges for electric vehicles-an essential factor for consumer adoption and market competitiveness.

- The region's increasing appetite for electric vehicles has propelled a notable surge in demand for lithium-ion batteries. Consequently, battery manufacturers and assemblers are now channeling investments into battery material production facilities. This strategic move aims to cater to the escalating need for lithium batteries, both on a domestic and international scale. Additionally, advancements in battery technology are further driving this demand. The market is expected to witness continued growth as electric vehicle adoption rises.

- For instance, in October 2023, Umicore, a significant player in electric vehicle battery materials, is solidifying its presence in Ontario, Canada, with the establishment of the CAM and pCAM plants. The company is actively building a 35 GWh battery materials production facility in Loyalist, ON, specifically tailored to cater to the burgeoning North American electric vehicle (EV) market.

- Recognizing the pivotal role this plant will play in bolstering the regional electric vehicle supply chain and enhancing the overall electric vehicle battery landscape, Umicore has secured significant financial backing from both the Canadian and Ontario governments.

- Therefore, as per the points mentioned above, the lithium-ion battery segment is expected to dominate the market during the forecasted period.

United States to Witness Significant Growth

- The United States segment has a robust and growing demand for electric vehicles, driven by a combination of consumer preferences, environmental awareness, and regulatory pressures to reduce greenhouse gas emissions. Federal and state-level incentives, such as tax credits and rebates for Electric Vehicle purchases, play a crucial role in accelerating the adoption of electric vehicles.

- In 2024, the available financial incentives include a tax credit of up to USD 7,500, while buyers of used electric cars might be eligible for up to USD 4,000. A notable change this year is that consumers can now choose to transfer this credit to a qualifying dealer, securing an instant discount on their vehicle purchase.

- These incentives not only make Electric Vehicles more affordable for consumers but also stimulate demand for advanced battery technologies and materials. Furthermore, the United States administration's commitment to achieving net-zero emissions by 2050 and the proposed infrastructure bill, which includes substantial investments in Electric Vehicle charging networks and clean energy initiatives, are expected to bolster the Electric Vehicle market further and, consequently, the demand for battery materials.

- These incentives have spurred a swift adoption of electric vehicles in the country. Notably, the International Energy Agency reports a steady rise in electric vehicle adoption over the past decade. Specifically, from 2022 to 2023, battery electric vehicle sales surged by over 37.5%. This growth is even more pronounced when considering the annual average rate over the past five years, which stood at an impressive 71.6%. Such figures underscore the escalating interest in electric vehicles, consequently boosting the demand for batteries in the nation.

- Significant investments in domestic battery manufacturing capabilities also characterize the United States segment. Recognizing the strategic importance of reducing dependence on foreign supply chains, both private sector players and government entities are investing heavily in the development of local battery manufacturing facilities. Companies like Tesla, General Motors, Hyundai, and Ford are spearheading efforts to establish gigafactories that produce lithium-ion batteries at scale.

- For instance, in April 2023, Two prominent automakers unveiled plans to construct electric vehicle (EV) battery plants in the United States, underscoring the continued rapid growth of electric vehicle manufacturing in the nation. General Motors, in collaboration with Samsung SDI, disclosed a joint investment of USD 3 billion for an electric vehicle battery plant in the United States. Concurrently, Hyundai revealed its partnership with South Korean battery manufacturer SK On, committing a substantial USD 5 billion to establish a battery factory in Georgia.

- These facilities aim to leverage advanced manufacturing technologies and automation to enhance production efficiency, reduce costs, and ensure a stable supply of high-quality batteries for the domestic market.

- Therefore, as mentioned above, the United States is expected to witness significant growth during the forecast period.

North America Electric Vehicle Battery Materials Industry Overview

The North America Electric Vehicle Battery Materials Market is moderately fragmented. Some of the key players in this market (in no particular order) are Targray Technology International Inc., BASF SE, Mitsubishi Chemical Group Corporation, UBE Corporation, and Umicore

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

Product Code: 50003557

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Scope of the Study

- 1.2 Market Definition

- 1.3 Study Assumptions

2 EXECUTIVE SUMMARY

3 RESEARCH METHODOLOGY

4 MARKET OVERVIEW

- 4.1 Introduction

- 4.2 Market Size and Demand Forecast in USD, till 2029

- 4.3 Recent Trends and Developments

- 4.4 Government Policies and Regulations

- 4.5 Market Dynamics

- 4.5.1 Drivers

- 4.5.1.1 Growing Electric Vehicle Sales

- 4.5.1.2 Supportive Government Policies and Regulations

- 4.5.2 Restraints

- 4.5.2.1 Dependence on Imported Raw Material Supply

- 4.5.1 Drivers

- 4.6 Supply Chain Analysis

- 4.7 Industry Attractiveness - Porter's Five Forces Analysis

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Consumers

- 4.7.3 Threat of New Entrants

- 4.7.4 Threat of Substitutes Products and Services

- 4.7.5 Intensity of Competitive Rivalry

- 4.8 Investment Analysis

5 MARKET SEGMENTATION

- 5.1 Battery Type

- 5.1.1 Lithium-ion Battery

- 5.1.2 Lead-Acid Battery

- 5.1.3 Others

- 5.2 Material

- 5.2.1 Cathode

- 5.2.2 Anode

- 5.2.3 Electrolyte

- 5.2.4 Separator

- 5.2.5 Others

- 5.3 Geography

- 5.3.1 United States

- 5.3.2 Canada

- 5.3.3 Rest of North America

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Strategies Adopted by Leading Players

- 6.3 Company Profiles

- 6.3.1 Targray Technology International Inc.

- 6.3.2 BASF SE

- 6.3.3 Mitsubishi Chemical Group Corporation

- 6.3.4 UBE Corporation

- 6.3.5 Umicore

- 6.3.6 Sumitomo Chemical Co., Ltd.

- 6.3.7 Nichia Corporation

- 6.3.8 ENTEK International LLC

- 6.3.9 Arkema SA

- 6.3.10 Kureha Corporation

- 6.4 List of Other Prominent Companies

- 6.5 Market Ranking/Share (%) Analysis

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Advancements in Battery Technology

Have a question?

SELECT AN OPTION

Have a question?

Questions? Please give us a call or visit the contact form.