Need help finding what you are looking for?

Contact Us

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1636420

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1636420

Germany Electric Vehicle Battery Anode - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

PUBLISHED:

PAGES: 100 Pages

DELIVERY TIME: 2-3 business days

SELECT AN OPTION

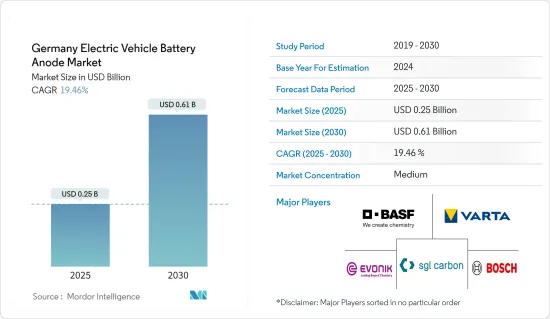

The Germany Electric Vehicle Battery Anode Market size is estimated at USD 0.25 billion in 2025, and is expected to reach USD 0.61 billion by 2030, at a CAGR of 19.46% during the forecast period (2025-2030).

Key Highlights

- Over the medium term, the growing EV adoption and technological advancements in anode materials are expected to drive the demand for electric vehicle battery anode during the forecast period.

- On the other hand, the high production costs of advanced anode materials, particularly those that are still in the experimental phase can significantly restrain the growth of the Germany electric vehicle battery anode market.

- Nevertheless, the growing focus on recycling and the circular economy presents opportunities for developing sustainable anode materials and the recycling processe are expected to create significant opportunities for electric vehicle battery anode market in the near future.

Germany Electric Vehicle Battery Anode Market Trends

Lithium-Ion Battery Type to Dominate the Market

- In Germany, the lithium-ion battery, especially in the electric vehicle (EV) sector, is pivotal to the nation's shift towards sustainable transportation. Being a global automotive powerhouse, Germany's government is deeply invested in pioneering advanced EV battery technologies, with a particular emphasis on the anode, a vital lithium-ion battery component.

- The anode, a key player in lithium-ion batteries, greatly affects the battery's performance, encompassing capacity, lifespan, and charging speed. Furthermore, the cost of lithium-ion batteries significantly impacts the pricing of electric vehicles. Thus, Germany's EV battery anode market holds paramount importance in the larger lithium-ion battery landscape.

- For instance, a Bloomberg NEF report highlighted that in 2023, battery prices in Germany dropped to USD 139/kWh, marking a 13% decline from the previous year. With ongoing technological innovations and manufacturing refinements, projections suggest battery pack prices will further dip to USD 113/kWh by 2025 and reach USD 80/kWh by 2030. As manufacturing efficiencies improve and lithium-ion battery production ramps up, the unit cost of battery anodes is also expected to decline during the forecast period.

- Moreover, ongoing innovations in anode materials are not only boosting battery performance but also making EVs increasingly competitive against traditional internal combustion engine vehicles. In light of this, regional governments have been fervently championing EV battery innovations in recent years.

- For instance, in May 2024, Theion, a Berlin-based battery innovator, showcased a groundbreaking leap in battery technology, spotlighting its novel anode chemistry. Theion's innovation, a lightweight polymer host with specialized coatings, aims to replace conventional anode materials such as graphite and silicon-rich graphite. Notably, this advancement boasts an impressive achievement of over 2,000 charging and discharging cycles. Such strides in battery technology are poised to bolster advanced battery production in the region, subsequently amplifying the demand for anodes in battery manufacturing.

- In Germany, the predominant use of anode materials is in crafting lithium-ion batteries for electric vehicles (EVs). These batteries power a diverse range of EVs, from passenger cars and commercial vehicles to public transportation systems. Major companies in the country have initiated multiple battery manufacturing projects to meet the surging demand across all EV categories.

- For instance, in January 2024, Northvolt, a prominent Swedish lithium-ion battery manufacturer, secured EU endorsement for a hefty EUR 902 million (USD 986.43 million) state aid package from Germany. This funding is earmarked for establishing an electric vehicle (EV) battery production facility in Heide, Germany. This initiative is set to bolster regional EV battery output and heighten the demand for anode materials in the foreseeable future.

- Given these developments, it's evident that such initiatives and innovations are poised to amplify lithium-ion battery production in the region, concurrently driving up the demand for EV battery anodes in the coming years.

Growing EV Adoption Drives the Market

- Germany's EV battery anode market is being driven by a surge in electric vehicle demand, influenced by changing consumer preferences and regulatory mandates. This momentum is bolstered by government incentives and technological advancements in batteries, setting the stage for continued market growth.

- As reported by the International Energy Agency (IEA), Germany witnessed electric vehicle sales reaching 0.7 million in 2023, a remarkable 5.5-fold surge since 2019. With the government rolling out a series of supportive policies, EV sales are poised for further growth in the coming years.

- Moreover, the German government's subsidies and incentives, aimed at curbing carbon emissions and championing electric mobility, play a crucial role in propelling the market. These initiatives encompass financial backing for EV purchases, tax incentives, and bolstering charging infrastructure, all of which amplify EV adoption and, consequently, the demand for battery anodes in lithium-ion battery production.

- Under the High-Tech Strategy 2025 and the European Battery Innovation project, the government is actively backing battery technology and EV-centric research. Notably, the government unveiled a substantial subsidy scheme: new EV buyers can avail up to EUR 6,000 (USD 6,500), while plug-in hybrid buyers can benefit from up to EUR 4,500 (USD 4,900). Such measures are set to boost EV production and, in turn, the demand for battery anodes in the foreseeable future.

- Additionally, the regional industry's pivot towards electric vehicles is evident. Major companies are ramping up investments and projects to bolster EV production. A case in point: Ford's announcement in June 2023 to inaugurate a USD 2 billion EV factory in Cologne, targeting an annual output of 250,000 vehicles. This Cologne facility is a stepping stone towards Ford's ambitious goal of 2 million annual EVs by 2026. Such undertakings not only amplify EV production but also signal a heightened demand for battery anodes.

- In summary, these concerted efforts and strategies are set to boost EV sales and, consequently, the demand for anode battery materials in the coming years.

Germany Electric Vehicle Battery Anode Industry Overview

The Germany electric vehicle battery anode market is moderate. Some of the key players (not in particular order) are BASF SE, Varta AG, SGL Carbon SE, Evonik Industries AG, Robert Bosch GmbH, among others.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

Product Code: 50003595

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Scope of the Study

- 1.2 Market Definition

- 1.3 Study Assumptions

2 EXECUTIVE SUMMARY

3 RESEARCH METHODOLOGY

4 MARKET OVERVIEW

- 4.1 Introduction

- 4.2 Market Size and Demand Forecast in USD, till 2029

- 4.3 Recent Trends and Developments

- 4.4 Government Policies and Regulations

- 4.5 Market Dynamics

- 4.5.1 Drivers

- 4.5.1.1 Growing Adoption of Electric Vehicles

- 4.5.1.2 Advancements in Anode Materials

- 4.5.2 Restraints

- 4.5.2.1 High Production Costs

- 4.5.1 Drivers

- 4.6 Supply Chain Analysis

- 4.7 PESTLE Analysis

- 4.8 Investment Analysis

5 MARKET SEGMENTATION

- 5.1 Battery Type

- 5.1.1 Lithium-Ion Batteries

- 5.1.2 Lead-Acid Batteries

- 5.1.3 Others

- 5.2 Material Type

- 5.2.1 Lithium

- 5.2.2 Graphite

- 5.2.3 Silicon

- 5.2.4 Others

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Strategies Adopted by Leading Players

- 6.3 Company Profiles

- 6.3.1 BASF SE

- 6.3.2 Varta AG

- 6.3.3 SGL Carbon SE

- 6.3.4 Evonik Industries AG

- 6.3.5 Robert Bosch GmbH

- 6.3.6 Innolith AG

- 6.3.7 Leclanche GmbH

- 6.3.8 Heraeus Holding GmbH

- 6.4 List of Other Prominent Companies

- 6.5 Market Ranking Analysis

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Circular Economy and Recycling

Have a question?

SELECT AN OPTION

Have a question?

Questions? Please give us a call or visit the contact form.