Need help finding what you are looking for?

Contact Us

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1690949

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1690949

North America Shrink And Stretch Film - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

PUBLISHED:

PAGES: 110 Pages

DELIVERY TIME: 2-3 business days

SELECT AN OPTION

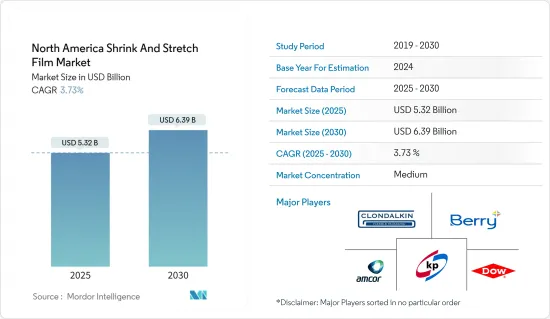

The North America Shrink And Stretch Film Market size is estimated at USD 5.32 billion in 2025, and is expected to reach USD 6.39 billion by 2030, at a CAGR of 3.73% during the forecast period (2025-2030).

Key Highlights

- Stretch and shrink films are polythene films made with advanced engineering. These films are used for packing items and have unique chemical properties that differentiate them in terms of flexibility and stretchability. Stretch films are thin polythene films that are flexible and elastic and are used to wrap around pallet loads, whereas shrink films are thin films wrapped around a single product or commodity and require heat to pack. These films help keep items from spoiling due to air and moisture, improving the quality of packed goods.

- Shrink sleeve labels refer to 360-degree printed labels that typically use heat in the application process to conform to the product's shape to which the label is applied. Shrink sleeve labels are printed on either side of the plastic or polyester film materials. The durability of the shrink sleeves makes them ideal for products that encounter moisture or friction.

- With various brands increasing their focus on sustainability goals for 2025, exploring more sustainability options is becoming increasingly central to meeting their pledges. Many bottled beverage producers are choosing recycle-ready polyethylene (PE) shrink film over corrugate and paperboard because it uses less energy and lowers greenhouse emissions in the distribution channel without compromising run speeds and machinability.

- Amcor stated that PE shrink is one of the most recycled types of plastic films in the United States, collected through the 18,000 in-store drop-off locations in North America. Expanding efforts to close the loop on a circular economy with post-consumer recycled (PCR) content can achieve additional sustainability benefits while providing the same versatility and performance as standard PE shrink films.

- In addition to their functional benefits, stretch and shrink films offer logistical advantages. The use of these films can significantly improve warehouse efficiency by enabling easier handling and storage of bulk products. Shrink-wrapped bundles, on the other hand, are compact and easier to stack, optimizing space utilization in storage facilities and vehicles. As a result, companies can achieve cost savings and improve overall operational efficiency in their supply chains.

North America Shrink and Stretch Film Market Trends

The Food and Beverage Industry is Witnessing Significant Market Growth

- Stretch film, primarily crafted from linear low-density polyethylene (LLDPE), is a cornerstone in the North American food and beverage industry. It is the go-to choice for palletizing, ensuring products remain secure during transit, thus averting potential damages from shifting. Renowned for its elasticity and robustness, this film adeptly conforms to products of varied shapes and sizes, providing stability and shielding against external elements like dust and moisture.

- On the other hand, shrink film, often fashioned from polyolefin or polyvinyl chloride (PVC), serves a distinct yet equally vital role. When subjected to heat, it contracts, snugly enveloping the goods and creating a secure seal. This feature makes it perfect for bundling items like bottles, cans, and boxes, simplifying handling and transportation. Furthermore, its tamper-evident seal is pivotal in upholding product integrity and bolstering consumer trust in the food and beverage domain.

- Both stretch and shrink films are pivotal in prolonging the shelf life of food and beverage items. Acting as a protective shield against contaminants such as dust, moisture, and microbes, these films are instrumental in preserving product freshness and quality. These factors are especially crucial for perishables, demanding stringent hygiene and temperature controls during storage and transit. By extending shelf life, these films not only combat food wastage but also ensure consumers receive products in prime condition.

- Enhancing product visibility and shelf appeal is another forte of stretch and shrink films. Shrink film, with its clear, glossy finish, elegantly showcases packaged products, a feature particularly prized in retail settings where visual allure can sway consumer choices significantly. Furthermore, manufacturers can directly print branding and product details on the film, reducing the need for additional labels and packaging materials, thereby streamlining the packaging process.

- According to data from the US Census Bureau for December 2023, monthly retail sales from US food and beverage stores hit around USD 90.3 billion, marking a notable 7.4% surge from the preceding month. This uptick in retail sales underscores the heightened demand for films, especially for packaging items like vegetables, fruits, fish, and meat.

The United States is Expected to Hold the Majority Share in the Market

- The rising demand for shrink and stretch films in the United States is primarily fueled by the growing need for effective packaging, bundling, and safeguarding of goods during warehousing and distribution. Additionally, the region hosts annual programs highlighting the robust demand for these films from consumer industries.

- With a notable surge in processed food consumption, the United States has witnessed a corresponding uptick in the need for stretch and shrink films. As consumers increasingly favor convenience foods, the importance of efficient packaging solutions has escalated. Shrink films, in particular, are in high demand, given their role in bundling and safeguarding items like frozen meals, snack packs, and ready-to-eat products.

- Shrink films, known for their ability to create a tight, tamper-evident seal, are especially prized in the realm of processed foods, ensuring both freshness and security. Furthermore, their clear, glossy finish not only enhances product visibility but also boosts shelf appeal, a crucial advantage in the fiercely competitive retail landscape. This visual allure, coupled with the protective attributes of shrink films, aids food companies in attracting consumers and ensuring product integrity.

- The significant consumption of beverage bottles is yet another driver for the demand for stretch and shrink films. Shrink films, in particular, are favored for crafting multi-packs of beverage bottles, such as six or twelve-packs. Their ability to snugly conform to bottle shapes ensures an appealing and stable package and makes them easier for consumers to handle. Moreover, the tamper-evident seal provided by shrink films further bolsters consumer confidence in product safety. Given the escalating consumption of bottled beverages in the United States, the demand for packaging solutions like stretch and shrink films is poised for a corresponding rise.

- Market players in the region have been actively innovating their products and launching new offerings to bolster their market standing and expand their customer base.

- According to the Beverage Industry Magazine, sales of private-label bottled still water in the United States surpassed USD 5.3 billion for 52 weeks ending May 21, 2023. This surge in bottled still water sales, driven by heightened consumer interest in healthy hydration, is poised to significantly impact the consumption of shrink and stretch films, further propelling demand for these materials.

North America Shrink and Stretch Film Industry Overview

The North American shrink and stretch film market is fragmented due to many players entering the packaging industry. Moreover, innovations and developments by players are making the market competitive.

- August 2023: Packaging solutions provider Group O was selected as one of the only distributors in North America to offer a new product that redefines sustainability in packaging. The product offered by the company is a first-ever machine-grade stretch film with 30% post-consumer recycled (PCR) content. This product marks a significant leap in the realm of packaging, where cutting-edge performance meets sustainability, shaping the future of responsible commerce.

- April 2023: Nosco Inc., a subsidiary of Holden Industries Inc., announced the launch of its exclusive EcoClear Film for StretchPak and other carded packaging applications. This PVC-free film was strategically developed to meet the sustainability demands of major retailers. It offers a crystal-clear display for enhanced product appearance.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

Product Code: 72593

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Consumers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Industry Ecosystem Analysis with an Emphasis on Circular Economy

- 4.4 Regulatory Framework

- 4.5 Shrink and Stretch Film Pricing Analysis

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Rising Demand From Industrial Sector

- 5.1.2 The Need for Tamper-evident Protection in Material Handling

- 5.2 Market Challenges

- 5.2.1 Recycling Challenges

6 MARKET SEGMENTATION

- 6.1 Product Type

- 6.1.1 Hoods

- 6.1.2 Wraps

- 6.1.3 Sleeve Labels

- 6.2 Material

- 6.2.1 Low-density Polyethylene (LDPE) and Linear Low-density Polyethylene (LLDPE)

- 6.2.2 Polyvinyl chloride (PVC)

- 6.2.3 Polyethylene terephthalate (PET)

- 6.2.4 Other Materials

- 6.3 End-use Industry

- 6.3.1 Food and Beverage

- 6.3.2 Consumer Goods

- 6.3.3 Pharmaceutical

- 6.3.4 Industrial

- 6.3.5 Other End-use Industries

- 6.4 Geography

- 6.4.1 United States

- 6.4.2 Canada

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Berry Global Inc.

- 7.1.2 Klockner Pentaplast Group

- 7.1.3 Amcor Group GmbH

- 7.1.4 Clondalkin Group Holdings BV

- 7.1.5 Dow Inc.

- 7.1.6 Taghleef Industries LLC

- 7.1.7 Sealed Air Corporation

- 7.1.8 Intertape Polymer Group Inc.

- 7.1.9 Emsur Macdonell SA

- 7.1.10 Transcontinental Inc.

- 7.2 Heat Map Analysis

- 7.3 Competitor Analysis - Emerging Vs. Established Players

8 INVESTMENT ANALYSIS

9 FUTURE OF THE MARKET

Have a question?

SELECT AN OPTION

Have a question?

Questions? Please give us a call or visit the contact form.