Need help finding what you are looking for?

Contact Us

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1636477

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1636477

Asia Pacific Electric Vehicle Battery Electrolyte - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

PUBLISHED:

PAGES: 110 Pages

DELIVERY TIME: 2-3 business days

SELECT AN OPTION

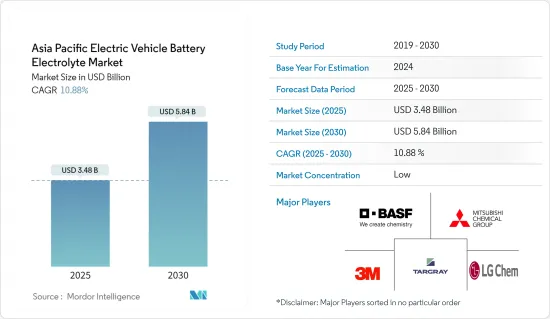

The Asia Pacific Electric Vehicle Battery Electrolyte Market size is estimated at USD 3.48 billion in 2025, and is expected to reach USD 5.84 billion by 2030, at a CAGR of 10.88% during the forecast period (2025-2030).

Key Highlights

- Over the medium term, the growing adoption of electric vehicles and advancements in battery technology across the region are expected to drive the demand for the electric vehicle battery electrolyte market during the forecast period.

- On the other hand, the technological challenges in Solid-State electrolytes can significantly restrain the growth of the electric vehicle battery electrolyte market.

- Nevertheless, the innovation in electrolyte formulations that improve battery performance, safety, and lifespan, particularly for high-performance or long-range EVs creates significant growth opportunities in the electric vehicle battery electrolyte market in the near future.

- India is anticipated to be the fastest-growing country in the Asia Pacific electric vehicle battery electrolyte market during the forecast period due to rising EV adoption.

Asia Pacific Electric Vehicle Battery Electrolyte Market Trends

Lithium-Ion Batteries Type to Witness Significant Growth

- The Asia Pacific EV battery electrolyte market plays a crucial role in the electric vehicle (EV) supply chain, being directly tied to the production of lithium-ion batteries, the primary energy storage solution for EVs. The region has witnessed a significant uptick in electric vehicle adoption, driven by stringent emissions regulations, government incentives, and a growing environmental consciousness. These factors are fueling the demand for lithium-ion batteries, subsequently boosting the need for battery electrolytes.

- Lithium-ion batteries are central to the EV ecosystem, valued for their high energy density, long cycle life, and low self-discharge rate. The cost of lithium-ion batteries plays a pivotal role in determining the overall price of electric vehicles, with electrolytes being a crucial component that directly influences these battery expenses.

- For example, a Bloomberg NEF report highlighted that in 2023, battery prices dropped to USD 139 /kWh, marking a 13% decline from the previous year. With ongoing technological advancements and manufacturing optimizations, battery pack prices are projected to dip further, forecasting USD 113/kWh in 2025 and an ambitious USD 80/kWh by 2030. As lithium-ion battery production ramps up, thanks to enhanced manufacturing efficiencies, bulk raw material procurement, and streamlined supply chains, the cost per unit of battery electrolytes is set to decrease during the forecast period.

- Moreover, ongoing research and development in lithium-ion batteries are birthing new electrolyte formulations that boost battery performance, safety, and lifespan. Recently, top research labs nationwide have been pioneering advanced electrolyte solutions for lithium-ion EV batteries.

- In July 2024, researchers from the Hong Kong University of Science and Technology (HKUST), in collaboration with several Asian universities, made headlines with a breakthrough in solid-state battery technology. They introduced a cutting-edge solid-state electrolyte (SSE) tailored for lithium-metal batteries (LMBs), showcasing significant advancements in safety and performance. Such breakthroughs are poised to amplify the demand for sophisticated lithium-ion batteries in EVs during the forecast period.

- Furthermore, leading battery manufacturers are ramping up production capacities in the Asia Pacific, responding to the surging EV demand, which in turn is propelling the electrolyte market. For instance, in February 2024, BMW unveiled plans for a new battery factory in Rayong, Thailand, aiming to bolster the nation's battery supply chains. The automaker envisions Thailand as a strategic export hub for EV batteries throughout the Asia Pacific, further strengthening the lithium-ion battery supply for EVs. Such initiatives are set to boost lithium-ion battery production in the coming years, subsequently elevating the demand for EV battery electrolytes during the forecast period.

- In conclusion, these initiatives and innovations are poised to not only amplify lithium-ion battery production in the region but also escalate the demand for EV battery electrolytes in the coming years.

India is Expected to Dominate the Market

- India is swiftly emerging as a key player in the Asia-Pacific electric vehicle (EV) market, spurred by a commitment to curbing carbon emissions and reducing reliance on fossil fuels. The government's ambitious EV adoption targets, notably through the Faster Adoption and Manufacturing of Hybrid and Electric Vehicles (FAME) scheme, have fostered a thriving environment for the growth of the EV battery market, including its electrolytes.

- In recent years, India has seen a notable uptick in EV sales, driven by heightened consumer demand, growing environmental consciousness, and government incentives like tax credits and rebates. This surge in EV adoption has, in turn, spurred a heightened demand for lithium-ion batteries and premium battery electrolytes.

- For instance, the International Energy Agency (IEA) reported that in 2023, electric vehicle sales reached 82,000 units, marking a 70.8% increase from 2022 and a staggering 119-fold jump from 2019. With the government rolling out a series of supportive policies, EV sales are poised for further growth in the coming years.

- As the industry pivots towards solid-state batteries, heralded for their superior energy density and safety, there's an anticipated demand for novel electrolytes. Recently, several companies have inked agreements to cater to the burgeoning need for solid-state batteries in the automotive realm.

- For instance, in October 2023, Idemitsu Kosan Co (Idemitsu) and Toyota Motor Corporation unveiled their partnership aimed at pioneering mass-production technology for solid electrolytes. Their collaboration seeks to bolster productivity and forge a resilient supply chain for battery electric vehicles (BEVs). With an eye on the future, both firms are ambitiously targeting the commercial rollout of these batteries by 2027-28, paving the way for expansive mass production thereafter. Such initiatives are set to amplify the demand for solid-state batteries and ensure a consistent supply of electrolytes for EV battery production during the forecast period.

- Additionally, the Indian government is actively championing the electric vehicle (EV) movement and promoting domestic battery manufacturing. Their strategy encompasses subsidies for EV purchasers, tax breaks for producers, and bolstered investments in charging infrastructure.

- For instance, in 2023, the Indian government set ambitious targets: by 2030, they aim for EVs to constitute 30% of private car sales, 70% of commercial vehicles, and 80% of two and three-wheelers. To further incentivize this shift, the government is offering subsidies ranging from INR 10,000 per kWh (USD 120) to INR 15,000 per kWh (USD 180). Such measures are poised to not only boost the demand for advanced EV batteries but also elevate the need for sophisticated EV battery electrolytes in the region during the forecast period.

- Given these developments, it's evident that the momentum in EV production and the corresponding demand for EV battery electrolytes is set to surge in the coming years.

Asia Pacific Electric Vehicle Battery Electrolyte Industry Overview

The Asia Pacific Electric Vehicle Battery Electrolyte market is semi-fragmented. Some of the key players (not in particular order) are 3M Company, BASF Corporation, Mitsubishi Chemical Group, Targray Technology International Inc, LG Chem Ltd, among others.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

Product Code: 50003744

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Scope of the Study

- 1.2 Market Definition

- 1.3 Study Assumptions

2 EXECUTIVE SUMMARY

3 RESEARCH METHODOLOGY

4 MARKET OVERVIEW

- 4.1 Introduction

- 4.2 Market Size and Demand Forecast in USD, till 2029

- 4.3 Recent Trends and Developments

- 4.4 Government Policies and Regulations

- 4.5 Market Dynamics

- 4.5.1 Drivers

- 4.5.1.1 Growing Adoption of Electric Vehicles

- 4.5.1.2 Advancements in Battery Technology

- 4.5.2 Restraints

- 4.5.2.1 Technological Challenges in Solid-State Electrolytes

- 4.5.1 Drivers

- 4.6 Supply Chain Analysis

- 4.7 Industry Attractiveness - Porter's Five Forces Analysis

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Consumers

- 4.7.3 Threat of New Entrants

- 4.7.4 Threat of Substitutes Products and Services

- 4.7.5 Intensity of Competitive Rivalry

- 4.8 Investment Analysis

5 MARKET SEGMENTATION

- 5.1 Battery Type

- 5.1.1 Lithium-ion Batteries

- 5.1.2 Lead-Acid Batteries

- 5.1.3 Others

- 5.2 Electrolyte Type

- 5.2.1 Liquid Electrolyte

- 5.2.2 Solid Electrolyte

- 5.2.3 Gel Electrolyte

- 5.3 Geography

- 5.3.1 China

- 5.3.2 India

- 5.3.3 Australia

- 5.3.4 Malaysia

- 5.3.5 Thailand

- 5.3.6 Indonesia

- 5.3.7 Vietnam

- 5.3.8 Rest of Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Strategies Adopted by Leading Players

- 6.3 Company Profiles

- 6.3.1 3M Company

- 6.3.2 BASF Corporation

- 6.3.3 LG Chem Ltd

- 6.3.4 Mitsubishi Chemical Group

- 6.3.5 Panasonic Holdings Corporation

- 6.3.6 UBE Industries, Ltd.

- 6.3.7 Asahi Kasei America, Inc.

- 6.3.8 Soulbrain Co., Ltd.

- 6.3.9 Dongwha Electrolyte Co.,Ltd.

- 6.3.10 Samsung SDI

- 6.3.11 Fujifilm Wako Pure Chemical Corporation

- 6.4 List of Other Prominent Companies

- 6.5 Market Ranking Analysis

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Innovation in Electrolyte Formulations

Have a question?

SELECT AN OPTION

Have a question?

Questions? Please give us a call or visit the contact form.