Need help finding what you are looking for?

Contact Us

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1636469

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1636469

ASEAN Countries Electric Vehicle Battery Manufacturing - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

PUBLISHED:

PAGES: 130 Pages

DELIVERY TIME: 2-3 business days

SELECT AN OPTION

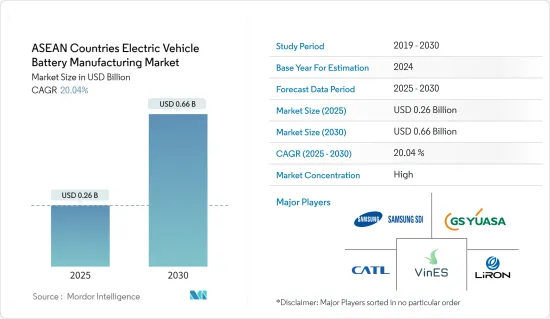

The ASEAN Countries Electric Vehicle Battery Manufacturing Market size is estimated at USD 0.26 billion in 2025, and is expected to reach USD 0.66 billion by 2030, at a CAGR of 20.04% during the forecast period (2025-2030).

Key Highlights

- Over the medium term, increasing adoption of electric vehicles (EV) and supportive government initiatives and investments to enhance battery production are expected to drive the demand for the ASEAN countries electric vehicle battery manufacturing market during the forecast period.

- On the other hand, the demand-supply mismatch of raw materials is expected to hinder the market's growth during the forecast period.

- Nevertheless, technological advancements in battery technologies and automaker-battery manufacturer collaborations are expected to create vast opportunities for countries' electric vehicle battery manufacturing markets in the future.

- Among all the countries in the region, Thailand is expected to witness significant growth due to the increase in the number of players participating in EV battery manufacturing.

ASEAN Countries Electric Vehicle Battery Manufacturing Market Trends

Passenger Vehicle Segment to Witness Significant Growth

- The battery manufacturing market for electric vehicles (EVs) in ASEAN (Association of Southeast Asian Nations) countries is poised for substantial growth, especially in the passenger vehicle segment. This surge is driven by the increasing adoption of EVs, government initiatives championing clean energy, and heightened consumer awareness of environmental concerns. In recent years, ASEAN nations, notably Indonesia, Malaysia, Thailand, Vietnam, and the Philippines, have emerged as pivotal players in the EV landscape.

- As reported by the ASEAN Automotive Federation (AAF), the ASEAN region produced a total of 2.748 million passenger vehicles in 2023, marking a 3.11% rise from the 2.665 million units produced in 2022. In 2023, the region's production stood at approximately 2.283 million units, up 3.21% from 2.212 million units in the previous year. Notably, Indonesia, Malaysia, and Thailand collectively accounted for over 83% of the region's passenger vehicle output.

- Looking ahead, the growth of passenger vehicles in the ASEAN region is anticipated to be bolstered by supportive government initiatives promoting electric vehicle adoption. This, in turn, is set to drive demand for EV batteries. Countries like Thailand, Indonesia, Singapore, Malaysia, and the Philippines are on track for rapid EV adoption, thanks to proactive government measures. For instance, the Philippines aims for EVs to constitute 21% of its total vehicles by 2030 and 50% by 2040. Additionally, the Electric Vehicle Association of the Philippines (EVAP) has upped its e-vehicle adoption target from 300,000 units in 2030 to a bold 1.0 million units, banking on anticipated sector incentives, clearer regulations, and growing EV benefits awareness.

- Indonesia's ambitions are equally pronounced, targeting 20% EV representation in car sales by 2025 and a domestic production goal of 600,000 EVs by 2030. These aspirations translate into concrete milestones across the EV supply chain, encompassing sales, production, and charging infrastructure, thereby propelling the EV battery manufacturing industry.

- In a testament to this momentum, Indonesia inaugurated its first electric vehicle battery plant in West Java in July 2024. This plant, a collaborative effort with a USD 1 billion investment from a consortium of Hyundai Motor Group, LG Energy Solution, and the Indonesia Battery Corporation, boasts an annual capacity of 10 gigawatt hours (GWh), sufficient for 150,000 EVs. The facility is seamlessly integrated with Hyundai's auto factory, which is set to produce 50,000 units annually of the Kona Electric vehicle. Furthermore, the consortium has ambitious plans to double the plant's capacity to 20 GWh, backed by an additional USD 2 billion investment.

- In 2023, the Department of Energy (DOE) of the Philippines set an ambitious target to deploy 6.3 million electric vehicles (EVs) by 2040, aiming for them to represent 50% of all vehicles on the road. This initiative will be supported by the installation of approximately 147,000 EV charging points over the same timeframe. In the short term, the DOE plans to roll out around 2.45 million electric cars, motorcycles, and buses by 2028. Such expansive plans underscore the burgeoning market for batteries in the passenger vehicle segment, further fueling the growth of the EV battery market.

- Given these dynamics, the passenger vehicle segment is set for significant expansion in the coming years.

Thailand to Witness a Significant Growth

- Thailand stands out as a prime destination for investments in the automobile sector. Over the past five decades, Thailand has transformed from merely assembling auto components to becoming a dominant hub for automotive production and exports in Southeast Asia. With rising investments from automakers, Thailand's battery industry is poised for steady growth, especially to support the burgeoning production of electric vehicles (EVs).

- As reported by the Electric Vehicle Association of Thailand (EVAT), Thailand registered approximately 100,219 battery electric vehicles (BEVs) in 2023, marking a staggering 380% surge from the previous year. Continuing this momentum, by the end of February 2024, Thailand recorded around 22,278 new BEV registrations, further amplifying the country's battery demand.

- The surge in EV adoption can be attributed to government incentives for buyers and supportive measures for manufacturers. For instance, Thailand's introduction of a purchase subsidy scheme for domestically produced EVs underscores its ambition to be a Southeast Asian EV production hub. The EV3.5 scheme, running from 2024 to 2027, offers subsidies between THB 50,000 (USD 1,397.02) and THB 100,000 (USD 2,794.04) per vehicle, highlighting the government's dedication to nurturing the EV sector and drawing in foreign investments.

- Thailand's strategic moves align with its vision of becoming a regional EV production center by 2030, aiming for EVs to make up 30% of all vehicle sales. Such endeavors position Thailand as a future hub for EV batteries, especially lithium-ion variants, presenting vast opportunities for battery manufacturers.

- In line with this vision, numerous battery manufacturers are ramping up their production capabilities in Thailand. A notable example is BMW Group, which in March 2024, broke ground on its 'Gen-5' high-voltage battery manufacturing facility. Situated in Rayong, on Thailand's east coast, the 4,000 square meter battery assembly is integrated into BMW's existing car plant. With plans to start rolling out EVs in the latter half of 2025, this new assembly line will play a pivotal role in BMW's global electrification strategy, converting imported battery cells into modules for high-voltage batteries. BMW has committed over EUR 42 million to this ambitious project.

- Given these developments, Thailand is poised to lead the electric vehicle battery manufacturing landscape in the ASEAN region during the forecast period.

ASEAN Countries Electric Vehicle Battery Manufacturing Industry Overview

The ASEAN Countries Electric Vehicle Battery Manufacturing market is moderately consolidated. Some of the key players in the market (not in any particular order) include Samsung SDI Co. Ltd., VinES Energy Solutions Joint Stock Company, Contemporary Amperex Technology Co. Ltd (CATL), LiRON LIB Power Pte Ltd and GS Yuasa Corporation.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

Product Code: 50003736

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Scope of the Study

- 1.2 Market Definition

- 1.3 Study Assumptions

2 EXECUTIVE SUMMARY

3 RESEARCH METHODOLOGY

4 MARKET OVERVIEW

- 4.1 Introduction

- 4.2 Market Size and Demand Forecast in USD, till 2029

- 4.3 Recent Trends and Developments

- 4.4 Government Policies and Regulations

- 4.5 Market Dynamics

- 4.5.1 Drivers

- 4.5.1.1 Increasing Adoption of Electric Vehicles

- 4.5.1.2 Supportive Government Initiatives and Investments to Enhance the Battery Production

- 4.5.2 Restraints

- 4.5.2.1 Demand-Supply Mismatch of Raw Materials

- 4.5.1 Drivers

- 4.6 Supply Chain Analysis

- 4.7 Industry Attractiveness - Porter's Five Forces Analysis

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Consumers

- 4.7.3 Threat of New Entrants

- 4.7.4 Threat of Substitutes Products and Services

- 4.7.5 Intensity of Competitive Rivalry

- 4.8 Investment Analysis

5 MARKET SEGMENTATION

- 5.1 Battery Type

- 5.1.1 Lithium-ion

- 5.1.2 Lead-Acid

- 5.1.3 Nickel Metal Hydride Battery

- 5.1.4 Other Battery Type

- 5.2 Vehicle Type

- 5.2.1 Passenger Vehicles

- 5.2.2 Commercial Vehicles

- 5.2.3 Other Vehicle Type

- 5.3 Propulsion

- 5.3.1 Battery Electric Vehicle

- 5.3.2 Hybrid Electric Vehicle

- 5.3.3 Plug-in Hybrid Electric Vehicle

- 5.4 Geography

- 5.4.1 Thailand

- 5.4.2 Indonesia

- 5.4.3 Philippines

- 5.4.4 Malaysia

- 5.4.5 Vietnam

- 5.4.6 Rest of ASEAN Countries

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Strategies Adopted by Leading Players

- 6.3 Company Profiles

- 6.3.1 Panasonic Corporation

- 6.3.2 Samsung SDI Co., Ltd.

- 6.3.3 Contemporary Amperex Technology Co. Ltd (CATL)

- 6.3.4 LG Energy Solution Ltd.

- 6.3.5 LiRON LIB Power Pte Ltd

- 6.3.6 GS Yuasa Corporation

- 6.3.7 VinES Energy Solutions Joint Stock Company

- 6.3.8 SVOLT Energy Technology Co., Ltd.

- 6.3.9 Energy Absolute Public Company Limited.

- 6.3.10 Exide Industries

- 6.4 List of Other Prominent Companies

- 6.5 Market Ranking Analysis

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Automaker-Battery Manufacturer Collaborations

- 7.2 Technological Advancements in Battery Technologies

Have a question?

SELECT AN OPTION

Have a question?

Questions? Please give us a call or visit the contact form.