PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1523352

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1523352

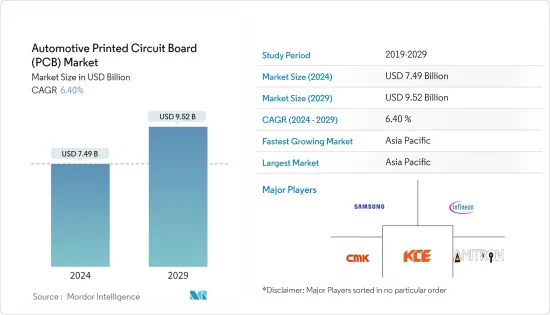

Automotive Printed Circuit Board (PCB) - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029)

The Automotive Printed Circuit Board Market size is estimated at USD 7.49 billion in 2024, and is expected to reach USD 9.52 billion by 2029, growing at a CAGR of 6.40% during the forecast period (2024-2029).

The increasing use of electrical systems in cars and the expanding need for driver comfort and safety in vehicles, coupled with significant expansion of the automotive sector, are anticipated to act as major driving factors for market growth during the forecast period.

Furthermore, with the increasing popularity of vehicle automation and the growing demand for connected cars across the world, the demand for automotive PCBs is expected to grow significantly during the forecast period.

The integration of Artificial Intelligence (AI), cloud, and IoT-enabled devices to improve and enhance vehicle and vehicle-to-infrastructure communication. AI-powered technologies, such as emotional and behavioral recognition and personal assistants, have been fueling the growth of safety and scenarios, such as Vehicle As A Marketplace, which in turn is likely to enhance the demand for power electronics components in vehicles. Thus further propelling the target market.

Over the long term, increasing investments in R&D by major industry players and a rise in sales of electric and hybrid vehicles, as well as rising demand for connected vehicles fare creating demand in the automotive and transportation industry with a surge in sales of automotive printed circuit boards.

Key players in the market are expanding their production capacity to cater to the increased demand for automotive printed circuit boards. For instance,

In July 2022, Denkai America Inc. announced that it would invest USD 430 million in Augusta, Georgia, to set up its North American HQ and manufacturing facility. The manufacturing facility will include a USD 150 million production line to manufacture ED copper foils for EV batteries. In March 2022, Ather Energy and Bharat FIH, a Foxconn Technology Group subsidiary, signed an agreement wherein Bharat FIH will develop and manufacture electric components for Ather Energy, including printed circuit boards (PCBs), in India.

Automotive Printed Circuit Board Market Trends

Growing Electric Vehicles Sales Driving the Market Growth

Many governments in some of the largest automotive markets like China, India, and Europe are relentlessly promoting the adoption of electric vehicles through various government incentives and policies aimed at boosting the sales of EVs to meet the carbon reduction goals under the Paris Climate Change Accord 2015 to which all these markets are signatories.

Sales of electric cars increased by around 60% in 2022 globally when compared to 2021, surpassing 10 million for the first time, even though car sales broadly were soft last year. As a result, one in every seven passenger cars bought globally in 2022 was an EV, according to the International Energy Agency (IEA). Nonetheless, electric vehicles are likely to outperform in 2023 as well. More than 2.3 million electric cars have been sold during the first quarter of 2023, which translates to a growth of about 25%, which is more than in comparison to the same period last year. In 2023, 14 million electric car sales are expected, representing 35% year-on-year growth; this will increase the market share of electric cars up to 18% in total car sales.

Various countries in Asia-Pacific and Europe have announced that they will ban the sales of new ICE vehicles by 2040 in favor of battery electric vehicles. Rising oil prices, growing pollution levels, increasing environmental consciousness, and a number of government incentives to promote electromobility are all contributing to very healthy growth in sales of EVs around the world. For instance,

In China, EV sales rose to 3.66 million units in 2022 (till September), posting a YoY growth of 119%, while in India, EV sales stood at 390,399 units (till July) in 2022, registering a YoY increase of 333%.

The emergence of electric turbochargers, also known as electrically assisted turbochargers or e-turbochargers, is a recent development. These systems utilize electric motors to enhance turbocharger performance and improve transient response, thereby reducing turbo lag.

An automotive PCB controls all the functions of a battery, which is the core component of an EV. Thus, the massive growth in sales of EVs is providing a very high impetus to the growth of the automotive PCB industry worldwide.

Owing to the increase in the demand for passenger cars and the growing awareness of electric mobility, significant players are ramping up the production capacity of their facilities. For instance,

In May 2023, Hyundai Motor India Limited announced an investment of INR 200 billion to enhance its electric vehicle manufacturing facility across India.

The increase in the trend of electric vehicles is expected to drive market growth in the future.

Asia-Pacific Region Anticipated to Grow at a Significant Level During the Forecast Period

The Asia-Pacific is the most dominant market, followed by North America and Europe.

Asia-Pacific is home to India, China, Japan, and South Korea, the world's largest automobile manufacturing countries. India and China are some of the world's largest markets for electric vehicles, contributing to almost 60% of worldwide electric vehicle sales, thus making Asia-Pacific the most lucrative market for automotive printed circuit boards. Automotive printed circuit boards are employed in the majority of these vehicles within the region to control the essential functions of an electric vehicle.

China is the largest manufacturer and consumer of electric vehicles in the world. Domestic demand is being supported by sales targets, favorable laws, and municipal air-quality targets. For instance,

China has imposed a quota on manufacturers of electric or hybrid vehicles, which must represent at least 10% of total new sales. Also, the city of Beijing only issues 10,000 permits for the registration of combustion engine vehicles per month to encourage its inhabitants to switch to electric vehicles. With increased vehicle sales and rapid urbanization, China is determined to reduce vehicle exhaust emissions. Meanwhile, the country intends to reduce its reliance on oil imports by increasing demand for and sales of electric vehicles.

An increase in vehicle production for exporting to other countries, along with the adoption of electric mobility in the country, are the key factors that are expected to boost the demand for power electronics and PCBs in China.

Europe and North America are also major markets due to the large presence of automotive OEMs and the rising electrification of the automotive industry, leading to high electric vehicle sales in these geographies. Thus, with companies coming up with innovations in this segment, the market for automotive Printed Circuit Boards is expected to grow over the forecast period for the electric vehicles segment. For instance, in June 2022, PCB Technologies launched iNPACK, a System-in-Package (SIP) solution that offers improved signal integrity and a significant reduction in unwanted inductance effects. The SIP solution can be utilized for a variety of applications in the automobile, consumer electronics, and medical devices industries.

Automotive Printed Circuit Board Industry Overview

The automotive PCB market is moderately consolidated. The market is characterized by the presence of some global and local players who have secured long-term supply contracts with major automotive OEMs in their respective regions. These players also engage in joint ventures, mergers and acquisitions, new product launches, and product development to expand their brand portfolios and cement their market positions.

Some of the major players dominating the global market are Samsung Electro-Mechanical Ltd, Infineon Corp., CMK Corp., KCE Electronics Ltd, and Amitron Corp. Many players are expanding their manufacturing capacity to secure their market position and stay ahead of the market curve. For instance, in February 2023, Elna PCB Malaysia Sdn Bhd announced a new PCB manufacturing plant in Penang, Malaysia, with mass production set to start in 2024. MYR's 1 billion investment budget has been set aside for the equipment, plant, and machinery, as well as the construction of this new plant that commenced in December 2022. This new plant will manufacture PCBs for automotive and electronic devices usage, among other products.

In April 2022, PT Infineon Technologies Batam, Indonesia, a wholly owned subsidiary of Infineon Technologies Corp, announced it would expand the backend production capacity in Indonesia by 2024. This expansion will see the Batam site become the second biggest one for Infineon Technologies Corp after their Melaka, Malaysia plant for automotive PCBs. Additionally, in June 2022, STMicroelectronics NV introduced a new high-voltage Printed Circuit board-based op amplifier for automotive and industrial applications.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Deliverables

- 1.2 Study Assumptions

- 1.3 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Rising EV Sales to Fuel Automotive PCB Demand

- 4.3 Market Restraints

- 4.3.1 Complex Design and Integration Challenges

- 4.4 Value Chain / Supply Chain Analysis

- 4.5 Porter's Five Forces Analysis

- 4.5.1 Threat of New Entrants

- 4.5.2 Bargaining Power of Buyers/Consumers

- 4.5.3 Bargaining Power of Suppliers

- 4.5.4 Threat of Substitute Products

- 4.5.5 Intensity of Competitive Rivalry

5 MARKET SEGMENTATION

- 5.1 By Vehicle Type

- 5.1.1 Passenger Cars

- 5.1.2 Commercial Vehicles

- 5.2 By Propulsion Type

- 5.2.1 IC Engine

- 5.2.2 Electric

- 5.3 By Type

- 5.3.1 Single Layer

- 5.3.2 Double Layer

- 5.3.3 Multi-Layer

- 5.4 By Application

- 5.4.1 ADAS

- 5.4.2 Body and Comfort

- 5.4.3 Infotainment System

- 5.4.4 Powertrain Components

- 5.4.5 Other Applications

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Rest of North America

- 5.5.2 Europe

- 5.5.2.1 Germany

- 5.5.2.2 United Kingdom

- 5.5.2.3 France

- 5.5.2.4 Rest of Europe

- 5.5.3 Asia-Pacific

- 5.5.3.1 India

- 5.5.3.2 China

- 5.5.3.3 Japan

- 5.5.3.4 South Korea

- 5.5.3.5 Rest of Asia-Pacific

- 5.5.4 Rest of the World

- 5.5.4.1 Brazil

- 5.5.4.2 United Arab Emirates

- 5.5.4.3 Other Countries

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Vendor Market Share

- 6.2 Company Profiles

- 6.2.1 Infineon Technologies AG

- 6.2.2 Samsung Electro Mechanics

- 6.2.3 CMK Corporation

- 6.2.4 Amitron Corporation

- 6.2.5 KCE Group

- 6.2.6 Daeduck Phil. Inc.

- 6.2.7 MEIKO ELECTRONICS Co. Ltd

- 6.2.8 CHIN POON Industrial Co. Ltd

- 6.2.9 Unimicron Group

- 6.2.10 STMicroelectronics NV

- 6.2.11 Tripod Technologies

7 MARKET OPPORTUNITIES AND FUTURE TRENDS