PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1644621

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1644621

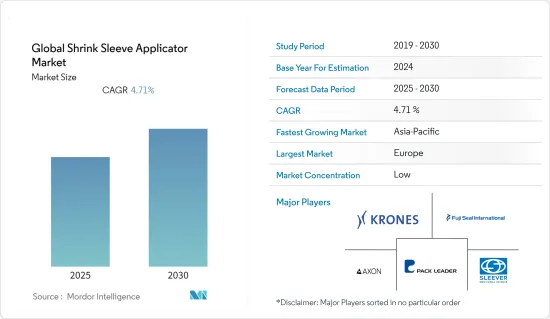

Global Shrink Sleeve Applicator - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

The Global Shrink Sleeve Applicator Market is expected to register a CAGR of 4.71% during the forecast period.

Shrink Sleeve Applicator is used for smooth, high speed, and efficient operations output. Shrink Sleeve applicators are very time efficient, giving a high-performance product range ensuring minimal cost with high-quality output using technology. Technological advancement related to packaging machinery is one of the crucial factors that propel the demand for shrink sleeve label applicators in the market.

Manufacturers promote and brand the packaged product with high quality and attractive labeling. This trend leads to an upsurge in demand for packaging machinery, which can efficiently achieve this goal. The shrink sleeve applicators are one of the best options to achieve this goal of manufacturers.

The rising demand for fully mechanized and automated equipment that can eliminate wastage and the versatility of handling glass and plastic containers are among the key drivers to propel the market in the future.

The COVID-19 outbreak caused significant disruption in the supply chain in the labeling and packaging industry and has affected the demand and supply chain. However, governments worldwide have deemed food and pharma-related businesses essential to offset the effects of covid 19 on the market. Changing trends to adapt packaged food because of hygiene will increase the demand for shrink sleeve applicators in the forecast period.

The shrink sleeve applicator market has been facing challenges like higher installation costs of machinery and new technological innovation with the use of cutting edge technologies in automation like plc, SCADA, and HMI in manufacturing units, and increasing trends towards eco-friendly labels soon may offset the market for the vendors.

Shrink Sleeve Applicator Market Trends

Food Packaging Accounted to Hold the Major Market Share

The use of shrink sleeve applicators in food packaging is mainly to enclose or wrap food products to protect them from tampering or contamination from chemical, physical, and biological sources, reflecting the manufacturer details the new laws made it mandatory to emboss the main ingredient on the packaging all these can be done efficiently and at a fast pace with Shrink Sleeve applicators.

With the increase in the population of over 9 billion, the manufacturers in the packaging industry require automation and equipment to achieve the task efficiently while maintaining quality. All these can be delivered by using shrink sleeve applicators with attractive and quality packaging. The quality and quantity of food packaging will have to increase considerably.

The food packaging industry is going through a transformation with the traditional breakthrough technology of casting labels. When it comes to labeling the product using shrink label applicators, the equipment now can integrate three to four trapping label machine varieties into one. It only needs to change the modules to realize the casting label of different types and varieties.

In 2004, the Food Allergy Labeling and Consumer Protection Act was passed, and In 1906, Food and Drugs Act (prohibited interstate commerce in misbranded and adulterated foods, drinks, and drugs.) in the United States. These regulations drive the shrink sleeve applicator market for the requirement of quality packaging and labeling of food products.

Advances in food packaging play a primary role in keeping the food supply safe, and keeping the label intact is very important because of customs regulations. Shrink sleeve applicator equipment ensures quality Packaging with perfect labeling maintaining standard labeling enabling food products to travel safely for long distances from their point of origin.

Europe Accounts to Hold the Major Share of the Market

As per the report published by the European Commission, the total EU agri-food trade reached a value of EUR 28.3 billion in January 2022, a 25% increase compared to 2021. Exports reached EUR 15.8 billion, while imports were valued at EUR 12.5 billion, representing an increase of 16% and 38%, respectively.

The successful promotion of the European union's open and accessible trade policy drives the success of European Union agricultural trade. The excellent reputation of products as sustainably produced, safe, nutritious, and of high quality reflected on the labels of the packaging products using the shrink sleeve applicators equipment is driving the market in the region.

Switzerland, China, the Middle East, and North Africa were the major growth regions for EU agri-food exports. The value of EU exports fell most to Turkey, the United States, Japan, and Singapore. The custom requirement for exports and imports requires the manufacturer to follow the regulatory laws regarding labeling the food products. Failing short may result in the rejection of the entire batch causing loss to the manufacturer. The shrink sleeve applicators' technological innovation labeling of various products becomes easy and efficient.

Before the Russian invasion, imports from Ukraine had grown by 88% YOY in January 2022 to reach a value of EUR 1 billion, primarily driven by cereals imports, which grew by EUR 258 million (136%). Elsewhere, imports from the US grew by 16%, while imports from China increased by 67%. Cereal shipping includes chances of rupturing the packages and spoilage of the product but can be avoided by using group packaging with a shrink sleeve aaplicator using PVC film (source: European Commission).

The largest export increase was noted to the United Kingdom, the United States, and China, for 40% of all EU agri-food exports. Exports to the UK grew by EUR 894 million (+36%) to 2020 levels after a sharp decline last year. The primarily increase in exports of vegetables, poultry & eggs, beer, and other beverages, processing and labeling of products at this level need technology, which can process the labeling at a very high rate maintaining the uniformity in quality which shrink sleeve applicators can achieve in no time.

Shrink Sleeve Applicator Industry Overview

The shrink sleeve labels market is competitive and simultaneously fragmented because of different domestic and international key players. These industry players have incorporated strategies to remain at the forefront and satisfy customers' increasing demand with collaborations, joint ventures, and new product launches.

May 2022 - Tripack LLC announced opening a manufacturing facility in Florida to fulfill the growing demand for decorated aluminum cans in the beverage industry. Tripack plans to open a third manufacturing facility in Lakeland, Florida with over 30,000 sq ft and space for multiple packaging lines.

May 2021 - CCL Industries Inc., a specialty label, security, and packaging solutions provider for government institutions, global corporations, consumers, and small businesses, announced the acquisition of Lux Global Label Asia Pte Ltd, based in Singapore.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Threat of New Entrants

- 4.2.2 Bargaining Power of Buyers/Consumers

- 4.2.3 Bargaining Power of Suppliers

- 4.2.4 Threat of Substitute Products

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Assessment of Impact of COVID-19 on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Recent trend of downgauging has been a major driver for the use of automated applicator machines as they contribute to lower consumption of sleeve label

- 5.1.2 Growing demand from Pharmaceutical and food sectors which currently account for a large share of the demand

- 5.2 Market Restraints

- 5.2.1 Stringent regulatory constraints pertaining to the visibility of labels remains a challenge across the supply chain

- 5.3 Evolution of Shrink Sleeve Applicators and recent advancements in technology

6 MARKET SEGMENTATION

- 6.1 By Equipment Type

- 6.1.1 Semi-automated & Manual

- 6.1.2 Automated

- 6.2 By End-user Vertical

- 6.2.1 Hard FM

- 6.2.2 Soft FM

- 6.3 By End-User

- 6.3.1 Food

- 6.3.2 Beverage

- 6.3.3 Pharmaceutical

- 6.3.4 Personal care & Cosmetics

- 6.3.5 Industrial (Chemicals & Automotive)

- 6.4 By Geography

- 6.4.1 North America

- 6.4.2 Europe

- 6.4.3 Asia-Pacific

- 6.4.4 Middle-East and Africa

- 6.4.5 Rest of the World

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Krones AG

- 7.1.2 Fujiseal International

- 7.1.3 Finpac Group

- 7.1.4 Pack Leader Machinery Inc.

- 7.1.5 Sleever International

- 7.1.6 Tripack Group

- 7.1.7 Axon Corporation

- 7.1.8 USLUGA SHPK

- 7.1.9 Label-Aire Corporation

- 7.1.10 Benison Group

8 RELATIVE POSITIONING ANALYSIS - TOP VENDORS TO BE RANKED BASED ON PRE-DEFINED CRITERIA

9 MARKET OUTLOOK