PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1849864

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1849864

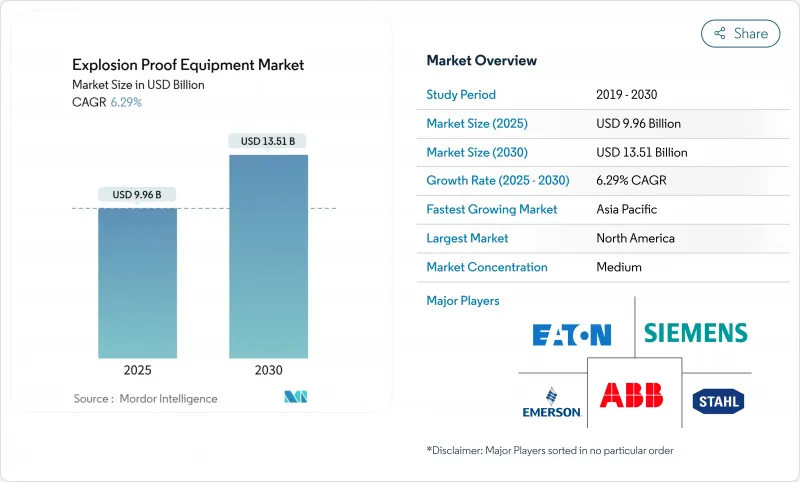

Explosion Proof Equipment - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

The explosion proof equipment market is valued at USD 9.96 billion in 2025 and is forecast to reach USD 13.51 billion by 2030, advancing at a 6.29% CAGR.

Expansion is underpinned by the universal enforcement of ATEX and IECEx rules, a quick build-out of green-hydrogen plants, and sustained capital spending on IIoT-ready retrofits that boost predictive maintenance in hazardous areas. Demand also benefits from the mass conversion to LED lighting in offshore and on-shore facilities and the ramp-up of lithium-ion gigafactories across Asia-Pacific, each requiring dust-zone-rated gear . North America preserves scale leadership through OSHA rules and ageing-asset modernization, whereas Asia-Pacific generates the fastest incremental volumes thanks to emerging hydrogen corridors, battery supply chains, and chemical processing clusters. The competitive landscape remains moderately fragmented as ABB, Siemens, and Eaton redeploy balance-sheet strength into local capacity while newcomers fill niche certification gaps. Near-term headwinds include casting shortages and tariffs on Chinese enclosures, which compress margins and encourage multi-sourcing

Global Explosion Proof Equipment Market Trends and Insights

Stricter Global ATEX/IECEx Enforcement

Regulators tightened ATEX guidelines in April 2024, intensifying conformity assessments and escalating testing volumes by 40% year-on-year. Turkey and South Korea mirrored the move through IECEx-aligned statutes, forcing suppliers to upgrade legacy lines that often run for 20 years. Multinationals welcome harmonization because one certificate now unlocks multi-region sales, compressing cycle times and lowering engineering variance. This regulatory rigor accelerates replacement demand across refineries, chemical parks, and LNG export hubs as managers rush to stay audit-ready.

Rising Green-Hydrogen Projects Needing Class I Equipment

Hydrogen's flammability range of 4-75% in air heightens ignition risk, mandating advanced containment, detection, and ventilation systems. Gigawatt-scale electrolyzer farms in China, Australia, and the Gulf are sourcing bespoke flame-proof switchgear and intrinsically safe sensors, creating a dedicated procurement channel inside the explosion proof equipment market. Suppliers with hydrogen-specific certificates secure early-mover margins, prompting portfolio carve-outs and R&D alliances across the value chain.

High Certification & Recertification Cost

End-to-end ATEX and IECEx validation can consume 15-25% of development budgets, while lab queues stretch to 6-12 months for sophisticated assemblies. Smaller firms struggle to finance multiple dossiers, spurring M&A and joint-venture formations as a risk-sharing tactic. As standards evolve, recertification cycles shave gross margins, nudging price adjustments downstream.

Other drivers and restraints analyzed in the detailed report include:

- Mainstream IIoT-Ready Explosion-Proof Retrofits

- Rapid LED Migration in Hazardous Lighting

- Divergent Regional Zoning Standards

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Flame-proof containment captured 46% of 2024 revenue, confirming its anchor role in the explosion proof equipment market. The design's rugged housings and service record underpin uptake in high-power pumps, compressors, and MCC panels, especially in mature oil & gas basins. However, intrinsic safety, growing 7.9% CAGR, exploits lower-power electronics, micro-sensors, and field-bus topologies that operate below ignition energy thresholds. As asset managers elevate digital diagnostics, intrinsic-safety designs will steadily dilute containment's percentage but enlarge the overall explosion proof equipment market size by funneling new sensor nodes into hazardous areas.

Pressurized and purged cabinets remain essential for large-frame VFDs and PLC suites, while explosion prevention linings and segregation modules serve specialty dust processes in battery plants. The shift towards energy-limiting pathways illustrates the market's pivot from 'contain' to 'prevent,' mirroring global safety philosophies and supporting long-term expansion.

Zone 1 retained 32% of 2024 revenue in the explosion proof equipment market, reflecting widespread industrial processes where vapors appear in routine operation. Operators favour certified luminaires, cable glands, and junction boxes to secure continuity during maintenance cycles. Yet Zone 0, forecast at 8.5% CAGR, garners capex priority within green hydrogen and deep-sea drilling where continuous explosive atmospheres demand the highest-grade hardware. This re-weights product-mix profitability even if total unit counts remain thinner.

Zone 2 projects generate high volumes for lower-spec gear, particularly across food, feed, and beverage plants transitioning from legacy setups. Dust Zones 21 and 22 accelerate as battery cathode and anode powders gain visibility after widely publicized fire events, compelling OEMs to design for fine particulate threats and escalating the explosion proof equipment market share for dust-rated products.

The Explosion Proof Equipment Market Segmented by Method of Protection (Explosion Segregation, Explosion Prevention, and More), by Zone (Zone 0, Zone 20, Zone 1, and More), by End-User (Pharmaceutical, Chemical and Petrochemical, and More), by System (Power Supply System, Material Handling, and More), and by Geography. The Market Size and Forecasts are Provided in Terms of Value (USD).

Geography Analysis

North America controlled 35% revenue in 2024, galvanized by NEC Articles 500-516 and recurring turnaround programs in petrochemical hubs along the Gulf Coast . United States refiners push mid-cycle revamps, while Canada outfits winterized SAGD units with low-temperature certified enclosures. High IIoT uptake plus LED retrofits elevate the regional average selling price, preserving robust EBIT margins within the explosion proof equipment market.

Asia-Pacific advances at 7.6% CAGR, building lithium-ion gigafactories, onshore chemical complexes, and offshore LNG trains that collectively swell the explosion proof equipment market size . China spearheads dust-zone deployments across battery parks, India channels PLI incentives into pharma and specialty chemicals, and Japan scales hydrogen valleys requiring bespoke Class I pneumatics. Regional suppliers fast-track IECEx lines, compressing lead times and embedding local service nodes.

Europe remains steady, anchored by Germany's ATEX expertise and the bloc's carbon-neutrality investments that extend plant life while aligning with Directive 2014/34/EU. The United Kingdom's policy continuity post-Brexit encourages ABB's USD 35 million R&D and factory upgrade, signalling positive sentiment for regional capabilities. Middle East and Africa rely on greenfield petrochemical and LNG megaprojects, whereas South America's momentum clusters around Brazil's ethanol and petrochemical corridor, together extending the global footprint of the explosion proof equipment market.

- ABB Ltd

- Eaton Corporation plc

- Siemens AG

- Honeywell International Inc.

- R. STAHL AG

- Pepperl+Fuchs GmbH

- Emerson Electric Co.

- Bartec GmbH

- Rockwell Automation Inc.

- Intertek Group plc

- Marechal Electric Group

- Adalet Inc.

- CZ Electric Co. Ltd

- MAM Explosion-proof Technology (Shanghai) Co. Ltd

- G.M. International SRL

- Alloy Industry Co. Ltd

- Hawke International

- Cooper Crouse-Hinds (Eaton)

- WEG Industries

- Advantech Co. Ltd

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions & Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Stricter global ATEX/IECEx enforcement

- 4.2.2 Rising green-hydrogen projects needing Class I equipment

- 4.2.3 IIoT-ready explosion-proof retrofits (mainstream)

- 4.2.4 Rapid LED migration in hazardous lighting

- 4.2.5 Lithium-ion gigafactories demand for dust-zone gear (under-radar)

- 4.2.6 Space-industry test stands requiring Ex-rated systems (under-radar)

- 4.3 Market Restraints

- 4.3.1 High certification and recertification cost

- 4.3.2 Divergent regional zoning standards

- 4.3.3 Supply-chain delays for flame-proof castings (under-radar)

- 4.3.4 Anti-dumping tariffs on Chinese Ex enclosures (under-radar)

- 4.4 Value / Supply-Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Porters Five Forces

- 4.7.1 Threat of New Entrants

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Bargaining Power of Suppliers

- 4.7.4 Threat of Substitutes

- 4.7.5 Competitive Rivalry

5 MARKET SIZE & GROWTH FORECASTS (VALUE)

- 5.1 By Method of Protection

- 5.1.1 Explosion Containment (Flame-proof)

- 5.1.2 Intrinsic Safety

- 5.1.3 Pressurization / Purged

- 5.1.4 Explosion Prevention

- 5.1.5 Explosion Segregation

- 5.2 By Zone

- 5.2.1 Zone 0

- 5.2.2 Zone 1

- 5.2.3 Zone 2

- 5.2.4 Zone 20

- 5.2.5 Zone 21

- 5.2.6 Zone 22

- 5.3 By End-user Industry

- 5.3.1 Oil and Gas

- 5.3.2 Chemicals and Petrochemicals

- 5.3.3 Mining and Metals

- 5.3.4 Energy and Power

- 5.3.5 Pharmaceuticals

- 5.3.6 Food and Beverage Processing

- 5.3.7 Waste-water Treatment

- 5.3.8 Hydrogen Production and Fuel Cells

- 5.3.9 Other Industries

- 5.4 By System

- 5.4.1 Power Supply and Distribution

- 5.4.2 Motors and Drives

- 5.4.3 Automation and Control Systems

- 5.4.4 Lighting Systems

- 5.4.5 Material Handling Equipment

- 5.4.6 Surveillance and Detection

- 5.4.7 Heating and HVAC

- 5.4.8 Other Systems

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 South America

- 5.5.2.1 Brazil

- 5.5.2.2 Argentina

- 5.5.2.3 Rest of South America

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Russia

- 5.5.3.5 Rest of Europe

- 5.5.4 Asia Pacific

- 5.5.4.1 China

- 5.5.4.2 Japan

- 5.5.4.3 India

- 5.5.4.4 South Korea

- 5.5.4.5 Rest of Asia Pacific

- 5.5.5 Middle East and Africa

- 5.5.5.1 GCC

- 5.5.5.2 Turkey

- 5.5.5.3 South Africa

- 5.5.5.4 Rest of Middle East and Africa

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global Overview, Market overview, Core Segments, Financials, Strategic Info, Rank/Share, Products & Services, Recent Developments)

- 6.4.1 ABB Ltd

- 6.4.2 Eaton Corporation plc

- 6.4.3 Siemens AG

- 6.4.4 Honeywell International Inc.

- 6.4.5 R. STAHL AG

- 6.4.6 Pepperl+Fuchs GmbH

- 6.4.7 Emerson Electric Co.

- 6.4.8 Bartec GmbH

- 6.4.9 Rockwell Automation Inc.

- 6.4.10 Intertek Group plc

- 6.4.11 Marechal Electric Group

- 6.4.12 Adalet Inc.

- 6.4.13 CZ Electric Co. Ltd

- 6.4.14 MAM Explosion-proof Technology (Shanghai) Co. Ltd

- 6.4.15 G.M. International SRL

- 6.4.16 Alloy Industry Co. Ltd

- 6.4.17 Hawke International

- 6.4.18 Cooper Crouse-Hinds (Eaton)

- 6.4.19 WEG Industries

- 6.4.20 Advantech Co. Ltd

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet Needs Assessment