PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1636581

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1636581

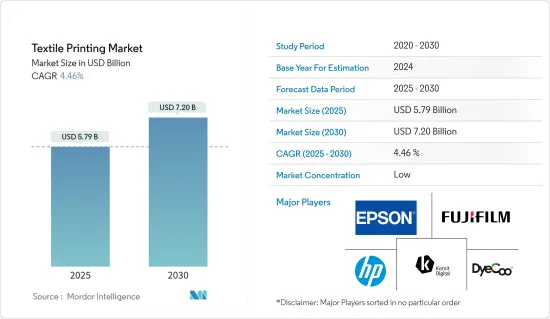

Textile Printing - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

The Textile Printing Market size is estimated at USD 5.79 billion in 2025, and is expected to reach USD 7.20 billion by 2030, at a CAGR of 4.46% during the forecast period (2025-2030).

The textile printing market is rapidly evolving, driven by technological advancements and the rising demand for customized, high-quality fabrics spurred by e-commerce and fast fashion growth. Key trends include the increasing adoption of digital printing technologies, which offer greater flexibility and efficiency than traditional methods.

As of January 2024, digital fabric printing is making significant inroads in China's Yangtze River Delta region, a primary textile production and export hub. This method employs inkjet technology, allowing for precise, vibrant designs on fabric while minimizing environmental impact through its eco-friendly technologies.

Innovations such as AI-powered design tools and sustainable printing practices are also reshaping the industry. At the Drupa trade fair in Dusseldorf, held from May 28 to June 7, 2024, Messe Dusseldorf introduced the Drupa Imaging Summit as part of the "Drupa Next Age" forum. The summit featured prominent industry leaders discussing the impact of artificial intelligence (AI) on imaging technologies and printing.

Notable presentations included Dennis Oberfeld from Google Cloud, who highlighted how AI is transforming image creation, and Andreas Jurgensen of AI Imagelab, who offered insights into current AI tools and their applications in image production.

Textile Printing Market Trends

H&M and Kyocera Launch Fabric Printing Innovations for Creators and Environment

In October 2023, Creator Studio, an on-demand fabric printing platform owned by the H&M group, launched an AI-powered solution that allows consumers to create and print customized graphics. This innovation aims to empower creators and streamline the content creation process, utilizing H&M's supply chain and fulfillment capabilities to offer sustainable and high-quality products. H&M, which owns brands like COS, Monki, and & Other Stories, is enhancing its technology-driven approach by integrating AI to optimize sourcing and sales data.

In February 2024, Kyocera introduced the Forearth inkjet printer, designed to address the textile industry's environmental challenges, such as water pollution and carbon emissions. The printer aims to reduce waste by minimizing the impact of fabric and water use.

Kyocera's deputy general manager, Sho Taniguchi, emphasizes the severity of textile pollution, citing that washing clothes releases microfibers equivalent to 50 billion plastic bottles into the ocean annually. Forearth offers a promising solution to decrease the fashion industry's environmental footprint by advancing textile printing practices.

Vietnam's Robust Demand for Woven Fabrics Signals Growth Opportunities in Textile Printing Industry

According to industry data, in 2022, Vietnam imported approximately USD 4.57 billion worth of woven fabrics made from man-made textile materials, making it the largest importer in this category globally. Bangladesh followed as the second largest importer, with around USD 2.14 billion. These fabrics' total global import value was USD 40.1 billion in 2022.

This substantial import value underscores Vietnam's robust demand for textile materials, positioning the country as a critical player in the global textile market. This strong demand indicates significant potential for the textile printing industry, driven by a thriving garment manufacturing sector requiring advanced printing solutions for domestic and international markets. As Vietnam continues to develop as a central textile production hub, the textile printing market is expected to see substantial opportunities for growth and innovation, catering to the increasing demand for high-quality printed fabrics.

Duy Tran, a leading automated printing enterprise in central Vietnam, is an example of this potential. The company serves major garment and textile manufacturers, working with over 50 global brands on over 500 projects and employing over 300 skilled workers. Duy Tran's technical advancement and capacity highlight the burgeoning opportunities within Vietnam's textile printing market, driven by local demand and international partnerships.

Textile Printing Industry Overview

The textile printing market is fiercely competitive, with leading players adopting diverse strategies to seize market share and spearhead innovation. Key players in this arena include Epson, Kornit Digital, Fujifilm, and DyeCoo Textile Systems. These players emphasize high-performance, customizable textile printers that cater to a broad spectrum of textile printing requirements.

Epson is bolstering its digital textile printing prowess at Innovation Center Building B, prioritizing high productivity and eco-friendliness with its SureColor F-Series printers. Kornit Digital focuses on on-demand, sustainable printing solutions, boasting high-performance printers for direct-to-garment and direct-to-fabric applications. Fujifilm harnesses its imaging expertise to deliver top-notch digital textile printers, whereas DyeCoo Textile Systems champions waterless dyeing technology, aiming to mitigate environmental repercussions.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Deliverables

- 1.2 Study Assumptions

- 1.3 Scope of the Study

2 RESEARCH METHODOLOGY

- 2.1 Analysis Methodology

- 2.2 Research Phases

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Current Market Scenario

- 4.2 Technological Trends

- 4.3 Insights on Supply Chain/Value Chain Analysis

- 4.4 Insights into Governement Regualtions in the Industry

- 4.5 Insights into Technological Advancements in the Industry

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Increasing Demand for Customization

- 5.1.2 Growth in E-commerce

- 5.2 Market Restraints

- 5.2.1 High Initial Investment

- 5.2.2 Environmental Concerns

- 5.3 Market Opportunities

- 5.3.1 Sustainable Printing Solutions

- 5.3.2 Integration of Smart Textiles

- 5.4 Industry Attractiveness - Porter's Five Forces Analysis

- 5.4.1 Threat of New Entrants

- 5.4.2 Bargaining Power of Buyers/Consumers

- 5.4.3 Bargaining Power of Suppliers

- 5.4.4 Threat of Substitute Products

- 5.4.5 Intensity of Competitive Rivalry

6 MARKET SEGMENTATION

- 6.1 By Printing Technology

- 6.1.1 Screen Printing

- 6.1.2 Digital Printing

- 6.1.3 Heat Transfer Printing

- 6.1.4 Others (Block, Stencil etc)

- 6.2 By Application

- 6.2.1 Apparel/ Clothing

- 6.2.2 Technical/ Industrial Textile

- 6.2.3 Home Textile & Others

- 6.3 By Region

- 6.3.1 North America

- 6.3.2 Europe

- 6.3.3 Asia Pacific

- 6.3.4 South America

- 6.3.5 Middle East & Africa

7 COMPETITIVE LANDSCAPE

- 7.1 Market Concentration Overview

- 7.2 Company Profiles

- 7.2.1 Epson

- 7.2.2 Kornit Digital

- 7.2.3 Fujifilm

- 7.2.4 DyeCoo Textile Systems

- 7.2.5 HP Inc.

- 7.2.6 Roland DG

- 7.2.7 MS Printing Solutions

- 7.2.8 Mimaki

- 7.2.9 Spoonflower

- 7.2.10 Juki Corporation*

- 7.3 Other Companies

8 MARKET OPPORTUNITIES AND FUTURE TRENDS

9 APPENDIX