PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1636580

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1636580

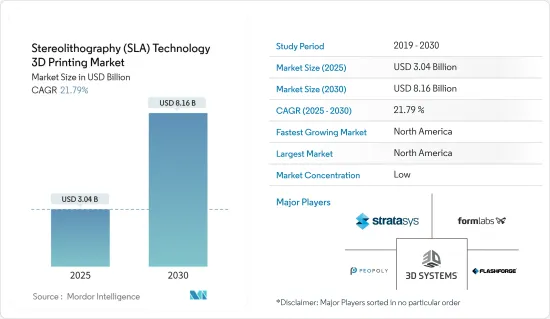

Stereolithography (SLA) Technology 3D Printing - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

The Stereolithography Technology 3D Printing Market size is estimated at USD 3.04 billion in 2025, and is expected to reach USD 8.16 billion by 2030, at a CAGR of 21.79% during the forecast period (2025-2030).

Key Highlights

- Stereolithography (SLA) technology stands out as a crucial component of the expansive 3D printing market, celebrated for its precision and capability to craft intricate components. A prominent trend in the SLA 3D printing arena is the relentless push towards enhanced printer speed and efficiency. Manufacturers are channeling efforts into crafting swifter laser systems and fine-tuning software algorithms, all aimed at curtailing print times without compromising on accuracy.

- Another noteworthy trend is the expanding array of resin materials. The availability of high-strength, temperature-resistant, biocompatible, and flexible resins has broadened SLA technology's appeal, serving sectors like healthcare, automotive, and aerospace. For example, in November 2024, Formlabs unveiled a fresh lineup of SLA resins, catering specifically to hobbyists and makers. This lineup features the Creator Tough Resin and Creator Super Clear Resin, both boasting impressive elongation at break. Their strength and transparency can be further accentuated through post-processing methods such as polishing and clear coatings.

- Moreover, the surge in affordability and user-friendliness of desktop SLA printers has spurred their adoption among small businesses, hobbyists, and educational entities. The move towards automation in post-processing is another pivotal advancement. With solutions for automated resin washing and curing, production workflows are becoming more streamlined, enhancing SLA's appeal for high-volume production. In September 2024, Formlabs enriched its portfolio by adding two new materials to its already extensive library of 45+, alongside introducing SLA and SLS post-processing tools. These additions aim to broaden 3D printing applications and simplify the journey for users to attain final, consumer-ready parts.

- However, the landscape isn't without its hurdles. A significant challenge lies in the steep initial investment for industrial-grade SLA printers and their associated equipment. This financial barrier often deters small and medium-sized enterprises from embracing SLA technology. Furthermore, the post-processing demands of SLA printing can be both labor-intensive and time-consuming. Once parts are printed, they undergo several essential post-processing steps: washing with alcohol, support material removal, and sanding. Typically executed manually, these tasks carry an inherent risk of human error.

Stereolithography (SLA) Technology 3D Printing Market Trends

Healthcare Sector is Expected to be the Fastest Growing Segment

- The SLA 3D printing market is being significantly propelled by the healthcare sector's demand for intricate and tailored medical solutions. This technology's prowess in crafting complex, patient-specific models and devices with unparalleled precision is reshaping the landscape of medical prototyping and production.

- SLA technology is pivotal in producing surgical guides, prosthetics, dental aligners, and anatomical models, enhancing both preoperative planning and patient communication. Companies are actively introducing products tailored for the dental and healthcare arenas. For example, in April 2024, Formlabs, a leader in stereolithography (SLA) and selective laser sintering (SLS), unveiled its first new 3D printer in half a decade, alongside a model tailored for dental and healthcare uses.

- Utilizing biocompatible and sterilizable resins has facilitated the creation of patient-specific medical devices, ensuring compliance with rigorous healthcare standards. Moreover, innovations in resin formulations for medical purposes have expanded SLA's applications, notably in orthopedics and bespoke implants.

- Furthermore, advancements in resin materials for SLA technology are propelling its adoption in the healthcare domain. For instance, Formlabs introduced six new resins, featuring four reformulated general-purpose variants, a fast model resin tailored for swift prototypes and orthodontic models, and a precision model resin designed for high-accuracy dental tasks.

- By leveraging biocompatible and sterilizable resins, the industry is producing patient-specific medical devices that adhere to stringent healthcare standards. Additionally, innovations in resin formulations, especially for medical uses, are expanding SLA's applications into fields like orthopedics and custom implants.

North America Holds One of the Largest Share

- North America's robust industrial foundation and substantial investments in advanced manufacturing technologies position it as a pivotal player in the SLA 3D printing market. The region boasts major 3D printing firms and widespread adoption across vital sectors, notably healthcare, aerospace, and automotive. With industry leaders like 3D Systems and Formlabs, North America is at the forefront of continuous innovation and the evolution of SLA solutions.

- In North America, the healthcare sector, especially in the U.S., has wholeheartedly adopted SLA 3D printing. Regional firms are introducing cutting-edge 3D printing hardware and materials tailored for healthcare, emphasizing their commitment to innovative solutions.

- For instance, Proclaim Health, a California-based company is revolutionizing dental flossing through 3D printing, aiming to develop a tool that enhances dental and gum health. Leveraging 3D printing, they're fine-tuning their design to prioritize functional aspects like surface quality, biocompatibility, translucency, and cost-effectiveness.

- Market growth is further bolstered by regulatory endorsements, such as the FDA's support for 3D-printed medical devices. Meanwhile, the aerospace and defense sectors harness SLA technology for prototyping and crafting lightweight, intricate components that adhere to stringent precision standards.

- Academic and research institutions in North America are pivotal, weaving SLA 3D printing into their curricula, driving innovation, and nurturing a workforce skilled in additive manufacturing. For instance, in 2024, Leigh University inaugurated a state-of-the-art 3D printing hub on its Mountaintop campus, responding to the surging demand for 3D printing resources. This hub now boasts an additional 10 filament printers and a cutting-edge, larger-scale SLA printer.

Stereolithography (SLA) Technology 3D Printing Industry Overview

Several global and regional players, driven by innovation and customization, dominate the market. Industries such as healthcare, automotive, and aerospace are increasingly adopting these innovations. Key players include 3D Systems, Formlabs Inc., Stratasys Ltd, Peopoly, FlashForge, etc. These companies utilize advanced material compatibility, high-precision printers, and streamlined workflows to serve both industrial and consumer applications.

Innovation is the cornerstone of competitive strategy. Companies are channeling investments into new resin formulations, achieving higher print resolutions, enhancing efficiency, and broadening material compatibility. Collaborations and partnerships play a pivotal role; for instance, major players are teaming up with software providers, material suppliers, and end-users to co-create application-specific solutions.

North America and Europe lead the SLA 3D printing market, bolstered by robust industrial bases and active R&D endeavors. In contrast, the Asia-Pacific region is swiftly emerging as a formidable contender, fueled by government initiatives, cost-effective manufacturing, and rising adoption across diverse sectors.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Consumers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 An Assessment of Impact of Macroeconomic Trends on The Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Growing Demand For Rapid Prototyping

- 5.1.2 Advancement in Resin Material

- 5.2 Market Restraints

- 5.2.1 High Initial Investment Costs

- 5.2.2 Post Processing Requirements

6 MARKET SEGMENTATION

- 6.1 By Application

- 6.1.1 Prototyping

- 6.1.2 Tooling

- 6.1.3 End-Use Products

- 6.1.4 Education and Research

- 6.2 By End-User Vertical

- 6.2.1 Automotive

- 6.2.2 Healthcare

- 6.2.3 Consumer Goods

- 6.2.4 Aerospace

- 6.2.5 Manufacturing

- 6.2.6 Education

- 6.3 By Geography

- 6.3.1 North America

- 6.3.2 Europe

- 6.3.3 Asia

- 6.3.4 Australia and New Zealand

- 6.3.5 Latin America

- 6.3.6 Middle East and Africa

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 3D Systems Inc.

- 7.1.2 Formlabs

- 7.1.3 Stratysys

- 7.1.4 Peopoly

- 7.1.5 XYZ printing

- 7.1.6 FlashForge

- 7.1.7 Zortrax

- 7.1.8 B9Creations

- 7.1.9 Shining 3D

- 7.1.10 Prusa Research a.s

- 7.1.11 Anycubic

- 7.1.12 Phrozen Technology

- 7.1.13 Kudo3D

- 7.1.14 Asiga

- 7.1.15 MiiCraft

- 7.1.16 Uniz Technology LLC

8 INVESTMENT ANALYSIS

9 FUTURE OF THE MARKET