Need help finding what you are looking for?

Contact Us

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1636538

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1636538

Electric Vehicle Battery Manufacturing Equipment - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

PUBLISHED:

PAGES: 125 Pages

DELIVERY TIME: 2-3 business days

SELECT AN OPTION

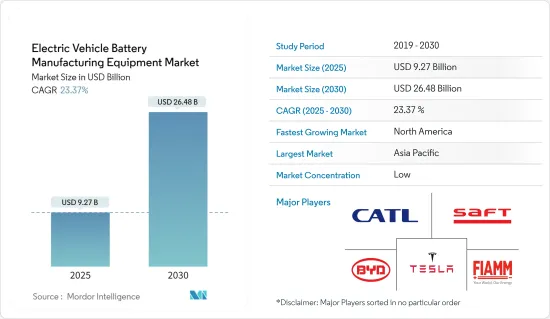

The Electric Vehicle Battery Manufacturing Equipment Market size is estimated at USD 9.27 billion in 2025, and is expected to reach USD 26.48 billion by 2030, at a CAGR of 23.37% during the forecast period (2025-2030).

Key Highlights

- Over the long term, the increasing adoption of electric vehicles and the decline in the cost of raw battery materials are expected to drive the market.

- On the other hand, the long-term dependency on internal combustion engine vehicles could hinder the rapid transition to electric vehicles, which may restrain the growth of the market.

- However, the growing technological advancements in higher capacity and low discharge rates are expected to make battery equipment more feasible and efficient and create enormous opportunities for the electric vehicle battery manufacturing equipment market.

- Asia-Pacific dominates the market, and its growth will be linked to rising investments and conducive government policies in countries such as India, China, and Australia.

Electric Vehicle Battery Manufacturing Equipment Market Trends

Rapid Adoption of Electric Vehicles to Dominate the Market

- The increasing cost fluctuations of gasoline and natural gas and the growing demand for emission controls in various countries have shifted the focus from conventional vehicles to electric vehicles (EVs). Electric vehicles are more efficient, which, combined with the lower cost of electricity, makes charging an electric vehicle cheaper than filling up with petrol or diesel for your travel needs. Using renewable energy sources can make electric vehicles more eco-friendly.

- Moreover, as the demand for electric vehicles increases, automobile manufacturing companies are designing electric vehicles for all car segments in various types and designs to increase their sales. This customization in automobile design provides a significant growth opportunity for battery manufacturing to meet automobile manufacturers' demands.

- In October 2023, BMW established its new battery cell pilot plant near Munich to fulfill its 'local for local' battery supply chain and production strategy. BMW Cell Manufacturing Competence Center (CMCC) will manufacture cylindrical cells, which is expected to boost the company's efficiency, quality, and stability in battery production and supply.

- The influx of electric vehicles in recent years is expected to propel the demand for battery manufacturing equipment during the forecast period. According to the International Energy Agency (IEA), the total sales of electric vehicles worldwide were 13.8 million in 2023, an increase from 10.2 million the previous year.

- By 2030, several countries have decided to increase the share of electric vehicles. For instance, countries like China aim to have 40% of vehicles sold by 2030 to be electric. With the growth in the EV population, battery demand is expected to witness significant growth. According to the International Energy Agency, by 2035, EV battery demand is expected to increase by seven times compared to 2023.

- Considering such a scenario, the automotive industry is expected to be the fastest-growing segment during the forecast period.

Asia-Pacific is Expected to Witness Significant Growth in the Market

- The electric vehicle battery manufacturing equipment market is constantly rising in Asia-Pacific due to the rising public awareness of environmental issues and techniques to improve constantly deteriorating conditions. Due to the region's large population and fast-growing economy, the demand for batteries in Asia-Pacific is expected to grow steadily, with countries such as China, India, and the ASEAN countries driving the market.

- China dominates the battery manufacturing equipment market with a significant electric car industry, leading industry players across the supply chain, and a rapidly rising economy. The region has the majority of the world's lithium-ion reserves. As per the International Energy Agency, the sales of electric cars in China in 2023 were about 8.1 million, from 5.9 million in the previous year. This appeared to be the highest in Asia-Pacific.

- The growth of electric vehicle battery manufacturing gigafactors in Asia-Pacific is expected to push its manufacturing equipment market in the coming years. For instance, in January 2023, the Recharge Industries firm noted that it would construct close to 2 GWh of annual electric vehicle battery production by 2024 and 6 GWh by 2026 in Australia's Geelong region. The gigagactory worth USD 300 million is expected to improve the country's electric battery supply-value chain.

- Government targets and initiatives to expedite the development of electric vehicles could further drive market growth in Asia-Pacific. For instance, in India, by 2030, the government aims for electric vehicles (EVs) to make up 30% of private car sales, 70% of commercial vehicle sales, and 80% of sales of two- and three-wheelers.

- Hence, Asia-Pacific is expected to dominate the market during the forecast period due to increased production, technological advancements, and supportive government policies in the electric vehicle battery equipment manufacturing market.

Electric Vehicle Battery Manufacturing Equipment Industry Overview

The electric vehicle battery manufacturing equipment market is fragmented, with several players. Some of the major players (not in particular order) include NEC Corporation, Duerr AG, Hitachi Ltd, Schuler AG, and Buhler Holding AG.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

Product Code: 50003971

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Scope of the Study

- 1.2 Market Definition

- 1.3 Study Assumptions

2 EXECUTIVE SUMMARY

3 RESEARCH METHODOLOGY

4 MARKET OVERVIEW

- 4.1 Introduction

- 4.2 Market Size and Demand Forecast in USD, till 2029

- 4.3 Recent Trends and Developments

- 4.4 Government Policies and Regulations

- 4.5 Market Dynamics

- 4.5.1 Drivers

- 4.5.1.1 Increasing adoption of electric vehicles

- 4.5.1.2 Decline in cost of battery raw materials

- 4.5.2 Restraints

- 4.5.2.1 Long-term dependency on internal combustion engine vehicles

- 4.5.1 Drivers

- 4.6 Supply Chain Analysis

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Consumers

- 4.7.3 Threat of New Entrants

- 4.7.4 Threat of Substitutes Products and Services

- 4.7.5 Intensity of Competitive Rivalry

- 4.8 Investment Analysis

5 MARKET SEGMENTATION

- 5.1 Process

- 5.1.1 Mixing

- 5.1.2 Coating

- 5.1.3 Calendering

- 5.1.4 Slitting and electrode making

- 5.1.5 Other Processes

- 5.2 Battery

- 5.2.1 Lithium-ion

- 5.2.2 Lead-acid

- 5.2.3 Nickel Metal Hydride Battery

- 5.3 Geography

- 5.3.1 North America

- 5.3.1.1 United States

- 5.3.1.2 Canada

- 5.3.1.3 Rest of North America

- 5.3.2 Europe

- 5.3.2.1 United Kingdom

- 5.3.2.2 Spain

- 5.3.2.3 NORDIC Countries

- 5.3.2.4 Turkey

- 5.3.2.5 Russia

- 5.3.2.6 Rest of Europe

- 5.3.3 Asia-Pacific

- 5.3.3.1 China

- 5.3.3.2 India

- 5.3.3.3 Malaysia

- 5.3.3.4 Thailand

- 5.3.3.5 Indonesia

- 5.3.3.6 Vietnam

- 5.3.3.7 South Korea

- 5.3.3.8 Rest of Asia-Pacific

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Colombia

- 5.3.4.4 Rest of South America

- 5.3.5 Middle East and Africa

- 5.3.5.1 United Arab Emirates

- 5.3.5.2 Saudi Arabia

- 5.3.5.3 Egypt

- 5.3.5.4 Nigeria

- 5.3.5.5 Qatar

- 5.3.5.6 Rest of Middle East and Africa

- 5.3.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Strategies Adopted by Leading Players

- 6.3 Company Profiles

- 6.3.1 NEC Corporation

- 6.3.2 Duerr AG

- 6.3.3 Hitachi Ltd

- 6.3.4 Schuler AG

- 6.3.5 Buhler Holding AG

- 6.3.6 Manz AG

- 6.3.7 Sovema Group S.p.A

- 6.3.8 Komatsu NTC Ltd

- 6.3.9 KROENERT GmbH & Co. KG.

- 6.4 List of Other Prominent Companies

- 6.5 Market Ranking Analysis

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Growing technological advancements in various technologies

Have a question?

SELECT AN OPTION

Have a question?

Questions? Please give us a call or visit the contact form.