Need help finding what you are looking for?

Contact Us

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1635362

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1635362

Asia-Pacific Pharmaceutical Packaging Machinery - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

PUBLISHED:

PAGES: 120 Pages

DELIVERY TIME: 2-3 business days

SELECT AN OPTION

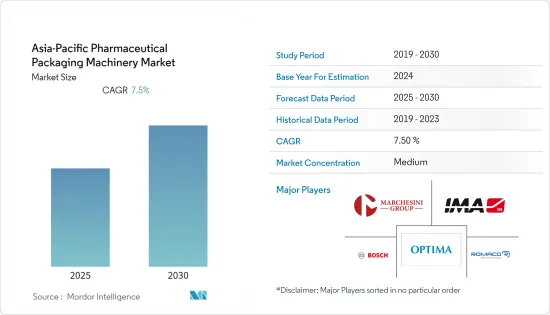

The Asia-Pacific Pharmaceutical Packaging Machinery Market is expected to register a CAGR of 7.5% during the forecast period.

Key Highlights

- Packaging pharmaceutical products and drug delivery systems are essential in the pharmaceutical industry. Pharmaceutical packaging machinery provides safety and quality in packaging pharmaceutical products.

- Pharmaceutical packaging refers to packaging products made by utilizing compatible materials that are used for the storage and transfer of drugs. Depending on the nature of the drug, packaging products are selected from a range of product types and material types to provide identification and protection and ensure the enclosed drug product's integrity. Thus, pharmaceutical packaging machinery offers primary packaging, secondary packaging, and labeling and serialization solutions for pharmaceuticals.

- The emergence of the COVID-19 pandemic has significantly impacted the market due to disruptions in the supply chain owing to extended factory closures and delayed production.

- The demand for pharmaceutical packaging machinery will increase over the next two to three years. During COVID-19, the vaccine suppliers have expanded their capacity to meet the rising demand. This scenario is expected to create new growth opportunities in the pharmaceutical packaging machinery market.

- The pharmaceutical packaging machinery market has a direct correlation with the pharmaceutical market. Any changes in demand for pharmaceutical drugs will positively impact the packaging machinery markets, as higher demand for new drugs leads to a greater need for packaging, thereby impacting the growth of the studied market.

APAC Pharmaceutical Packaging Machinery Market Trends

The Presence of Safety Standards & Regulations in the Pharmaceutical Industry Expected to Drive the Market

- The Pharmaceutical packaging machinery used in the pharmaceutical sector is heavily regulated and emphasizes safety and sustainability. Traceability legislations across the healthcare sector have been established to counter counterfeit drugs and medical devices.

- Pharmaceutical packaging machinery plays an integral role in the wider pharmaceutical supply chain. Packaging machinery helps to ensure all pharmaceutical products are safely distributed, tracked, and identified.

- The demand for Pharmaceutical packaging machinery is growing in China. Pharmaceutical packaging products are made using compatible materials to transfer and store drugs. Depending upon the nature of the drug, packaging machinery is chosen from a range of material types and product types, providing, protection and identification and ensuring the enclosed drug product's integrity.

- According to National Medical Products Administration (NMPA), the number of new drug approvals in China hit a high record in 2021. 61 new drugs were approved by NMPA, up from 46 in 2020. "New drug" is defined in this article as new chemical drugs or new biological products approved for the first time in China, excluding any new indications, new dosage forms, or a new combination of approved drugs. This will create more demand for the pharmaceutical Packaging Machinery Market.

- The industry depends on the pharmaceutical packaging market, which follows strict guidelines and offers specialized, advanced technologies. The scenario is propelling providers of pharmaceutical packaging machinery to work on innovations to deliver sophisticated solutions to cater to end-users' needs.

- Several companies have introduced advanced blister lines to accelerate production and output. These automated, integrated lines are expected to package blisters into desirable cartons and bundle them quickly.

- Furthermore, some leading vendors have introduced holistic solutions involving quality inspection, production, and packaging machinery. These platforms involve various equipment, from serialization units to blister/carton packaging machinery and tablet presses to trace and track applications. These automated solutions reduce human-machine interactions and impeccably control high-precision, contamination-free equipment.

India is Expected to Register a Significant Growth During the Forecast Period

- India is leading in providing generic pharmaceuticals (generic drugs) globally. Indian pharmaceutical sector supplies over 50% of global demand for various vaccines, 40% of generic demand in the U.S., and 25% of all medicine in the U.K. Globally.

- In India, The pharmaceutical industry has evolved considerably, owing to various factors that include the growth in regulatory norms and focus on population health management and invention. In addition, the increase in the demand for over-the-counter medicines and a more informed customer base are also driving the market growth in India.

- According to the CPhI Pharma Index 2020, India is viewed as the primary beneficiary of active pharmaceutical ingredient (API) manufacturing and contract research organization (CRO) chemistry services outsourcing, rebalancing away from China. India has become a global pharmaceutical manufacturing hub for generic drugs and vaccines. For Instance, the Serum Institute of India is one of the largest vaccine manufacturers in India, exporting vaccines worldwide.

- India has a superior advantage, over many countries, in the basic manufacturing of medical drugs and products due to resources, such as a large workforce and WHO-GMP (Good manufacturing practices)-approved production principles.

- Further, India's pharmaceutical manufacturing organization has been strongly attracting investment from global private equity firms, which is driven by relaxations offered by the government, such as increasing the foreign direct investment (FDI) limit from 49% to 74% in brownfield pharma ventures and a thriving generic drugs market. For Instance, in August 2021, Cipla Limited, an Indian drugmaker, and Kemwell Biopharma, a large pharmaceutical contract manufacturing organization (CDMO) located in India, announced the signing of a joint venture agreement to develop, manufacture, and distribute biosimilars for the worldwide market.

- Furthermore, pharma companies in the country are actively increasing their manufacturing capacities due to increased demand in the market. For Instance, in June 2021, Centrient Pharmaceuticals announced that it had started manufacturing at its new statins manufacturing facility by building its second dedicated unit in the Toansa site in India. The company aims to double its statins production capacity to meet the growing demand for Atorvastatin and Rosuvastatin Active Pharmaceutical Ingredients.

- Moreover, it is observed that the development of COVID-19 vaccines has led the combined companies to set up agreements with packaging companies for manufacturing vials and syringes. Such packaging trends act is one of the major growth drivers in the packaging machinery market.

- Also, expanding vaccine capacities have led the allied packaging engineering companies and OEMs to witness increasing demand for aseptic filling lines. As a result of such trends, pharmaceutical packaging machinery players are launching completely integrated systems and plug-and-play solutions with modular concepts.

APAC Pharmaceutical Packaging Machinery Industry Overview

The Asia-Pacific Pharmaceutical Packaging Machinery Market is moderately competitive and consists of several major players such as Robert Bosch GmbH, Romaco Pharmatechnik GmbH, Optima Packaging Group GmbH, Marchesini, MULTIVAC Group, PAC Machinery Group, etc. In terms of market share, few major players currently dominate the market. Mergers and acquisitions among pharmaceutical packaging machinery industries drive the market's growth.

- In October 2021, Marchesini Group acquired Dott. Bonapace and entered the small industrial production business. With this move, Marchesini Group acquired 70% of the shares in Dott. Bonapace expanded its vast machine park with novel technologies that manage special products such as capsules and suppositories.

- In February 2021, ProMach acquired Serpa Packaging Solutions, a manufacturer of cartoning and end-of-line packaging systems for the pharmaceutical, medical device, nutraceutical, food, cosmetics, and personal care markets. The addition of Serpa brings automated cartoning systems into ProMach's portfolio and expands its specialized secondary packaging machinery and line integration capabilities.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

Product Code: 91540

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Overview

- 4.2 Industry Value Chain Analysis

- 4.3 Industry Attractiveness - Porter's Five Forces Analysis

- 4.3.1 Bargaining Power of Buyers/Consumers

- 4.3.2 Bargaining Power of Suppliers

- 4.3.3 Threat of Substitute Products

- 4.3.4 Threat of New Entrants

- 4.3.5 Intensity of Competitive Rivalry

- 4.4 Impact of COVID-19 on the Packaging Machinery Industry

- 4.5 Market Drivers

- 4.5.1 High demand in key end-user markets

- 4.5.2 Ongoing technological developments

- 4.5.3 Impact of Safety Standards and Regulations in the pharmaceutical industry

- 4.6 Market Restraints

- 4.6.1 High costs and import duties pose a challenge for new customers

- 4.6.2 Capital Intensive manufacturing process

5 TECHNOLOGY SNAPSHOT

6 MARKET SEGMENTATION

- 6.1 By Machinery Type (Overview, Forecasts, Key Trends and Market Outlook)

- 6.1.1 Primary Packaging

- 6.1.1.1 Aseptic Filling and Sealing Equipment

- 6.1.1.2 Bottle Filling and Capping Equipment

- 6.1.1.3 Blister Packaging Equipment

- 6.1.1.4 Others

- 6.1.2 Secondary Packaging

- 6.1.2.1 Cartoning Equipment

- 6.1.2.2 Case packaging Equipment

- 6.1.2.3 Wrapping Equipment

- 6.1.2.4 Tray Packing Equipment

- 6.1.2.5 Others

- 6.1.3 Labelling and Serialization

- 6.1.3.1 Bottle and Ampule Labelling and Serialization Equipment

- 6.1.3.2 Carton Labelling and Serialization Equipment

- 6.1.3.3 Others

- 6.1.1 Primary Packaging

- 6.2 By Region (Overview, Forecasts, key Trends and Market Outlook)

- 6.2.1 China

- 6.2.2 India

- 6.2.3 Japan

- 6.2.4 South Korea

- 6.2.5 Rest of APAC

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Robert Bosch GmbH

- 7.1.2 Romaco Pharmatechnik GmbH

- 7.1.3 Optima Packaging Group GmbH

- 7.1.4 Marchesini

- 7.1.5 Mesoblast

- 7.1.6 I.M.A Industria Macchine Automatiche S.p.A

- 7.1.7 MULTIVAC Group

- 7.1.8 Ishida Co. Limited

- 7.1.9 PAC Machinery Group

- 7.1.10 Uhlmann Group

8 INVESTMENT ANALYSIS

9 FUTURE OUTLOOK OF THE MARKET

Have a question?

SELECT AN OPTION

Have a question?

Questions? Please give us a call or visit the contact form.