PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1629776

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1629776

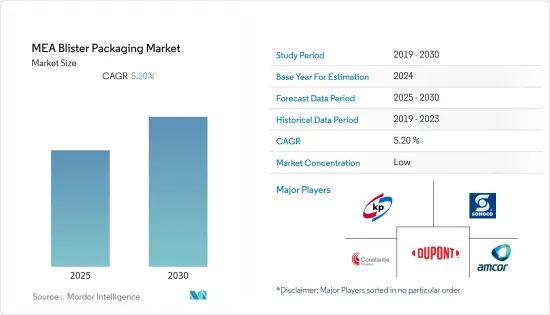

MEA Blister Packaging - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

The MEA Blister Packaging Market is expected to register a CAGR of 5.2% during the forecast period.

Key Highlights

- Blister pack is a term for several types of pre-formed plastic packaging used for small consumer goods, foods, and pharmaceuticals. These packaging solutions are useful for protecting products against external factors, such as humidity and contamination, for extended periods of time. Opaque blisters also protect light-sensitive products against UV rays. Such a wide base of applications has helped it gain traction in the market.

- Increasing pressure on pharmaceutical companies to manufacture medicines that are distinct in packaging and hard to imitate, beyond the basic need of keeping it effective for the purpose it was produced, for it to be made available for patients, owing to rise in diseases and stringent government regulations against counterfeit drugs, are among the major factors propelling the market. Blister packaging offers an efficient method of anti-counterfeit systems, like banknote authentication systems and others.

- The rising need for a level of product safety from manufacturers, consumers, and regulatory organizations makes blister packaging an increasingly practical option. Factors like product integrity and extended shelf life are highly necessary for the pharmaceutical sector, considering that most consumers store their drugs in a temperature variant atmosphere that can be harmful to unprotected medicines.

- The growing need for compliance with safety regulations, coupled with increased demand for convenient and easy-to-use packaging products, is also expected to drive the growth of the market studied and result in the market vendors partnering with technology companies to introduce those features and widen their product differentiation advantages for bulk purchasers.

- Moreover, the region is witnessing traction for eco-friendly blister packaging. For example, Sonoco offers EnviroSense, a paper blister for retail packaging, and is designed as an alternative to plastic blister packages. Additionally, with this, the comany has aimed to reduce the use of plastic by the end of 2025

MEA Blister Packaging Market Trends

Pharmaceutical is Expected to Witness a Significant Growth

- The pharmaceutical sector poses a different set of demands for blister packaging solutions, concerning insulation from external surroundings, cost-effectiveness, high levels of protection, and the ease of handling and retaining the effectiveness of the medicine. These packs are uniquely suited to meet stringent regulations and are highly valued for protective properties, cost-effectiveness, adaptability, and the pharmaceutical and packaging industry's requirements.

- When medicines are blister packaged, adherence is improved because consumers can keep track of their medications and dosage. The unit dosage feature of blisters reduces the risk of incorrect dosing.

- The retail-level preparation of prescription drugs is troubling pharmaceutical technicians or pharmacists. The administration of medicines in the open atmosphere of the supermarket and drug store may negatively affect sensitive medicines when they are transferred from container to container. Blister packaging can guarantee the process of distribution directly to the customer.

- Protecting product integrity continues to be the primary goal of pharmaceutical packaging, but there is continued work on cost reduction in the packaging process in all areas of the packaging industry.

- For Example, The Polybar barrier films product families provided by Amcor cover a wide range of moisture barriers whilst also providing good crush resistance to ensure the best protection for pharmaceutical applications such as tablets and capsules. It uses materials such as Aclar, COC, PE, PVC, and PVdc, among others.

- However, due to the supply chain disruption caused due to the impact of COVID-19, the exports of pharmaceutical products decreased across Africa in 2020. For instance, according to Trade Map, the value of pharmaceutical products exported from Morocco reduced to USD 109.9 million in 2020 compared to USD 117.08 million in 2019.

Africa to hold the Largest Market Share

- Blister packaging in the country is widely used to contain the APIs manufactured by various CMO vendors. In the MEA region, South Africa is known as one of the largest CMO markets in Africa. Some of the major factors responsible for South Africa's attractive pharmaceutical contract manufacturing are its well-established and stable markets and high turnover to investments.

- The tax structures and duties are possible challenges for foreign companies that aim to enter the market. On the other hand, increasing governmental support, rising health expenditure, and initiatives taken to support innovations in drug formulation and pharmaceutical interest are expected to bolster the opportunities available in the country.

- Moreover, Nigeria is one of the most promising and rapidly growing pharmaceutical manufacturing regions in West Africa, with more than 150 pharmaceutical formulation manufacturing facilities. The major drivers of growth in pharmaceutical contract manufacturing are cost advantage, increased demand for biological production, government regulations, and patent expiry.

MEA Blister Packaging Industry Overview

The Middle East and Africa Blister Packaging are highly concentrated. Partnership, mergers, and acquisitions have been a significant strategy for the vendors in the market for producing products that are acceptable in the end-user industry, where packaging materials undergo stringent quality tests not to contaminate the contents impact health. Maintaining a continuous flow of raw materials remain a challenge that prompts partnerships. Some of the major players in the market are Amcor Ltd, Sonoco Products Company, Constantia Flexibles GmbH, Honeywell International Inc., among others.

- April 2021- Amcor announced customer trials for recyclable Polyethylene-based thermoform blister packaging. The new packaging is designed to meet the stringent requirements of highly specialized and regulated pharmaceutical packaging and creates a more sustainable alternative for the most in-demand healthcare packaging type. This innovation also benefits from up to 70% reduction in its carbon footprint when compared to packaging alternatives on the market.

- July 2021 - Huthamaki launched Push Tab paper-based blister solution for the healthcare industry. The paper used by the comany is FSC certified and acts as an alternative to traditional push-through packaging made of thermoformed PVC and aluminum, thus reducing the environmental impact across the value chain.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Growing geriatric population and prevalence of diseases

- 4.2.2 Product innovations such as downsizing coupled with relatively low costs

- 4.3 Market Challenges

- 4.3.1 Dynamic nature of regulations and inability to support heavy goods

- 4.4 Industry Attractiveness - Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Consumers

- 4.4.3 Threat of New Entrants

- 4.4.4 Intensity of Competitive Rivalry

- 4.4.5 Threat of Substitutes

- 4.5 Assessment of the impact of COVID-19 on Blister Packaging Market

5 MARKET SEGMENTATION

- 5.1 By Process

- 5.1.1 Thermoforming

- 5.1.2 Coldforming

- 5.2 By Material

- 5.2.1 Plastic Films

- 5.2.2 Paper and Paperboard

- 5.2.3 Aluminum

- 5.2.4 Other Materials

- 5.3 By End-User Industry

- 5.3.1 Consumer Goods

- 5.3.2 Pharmaceutical

- 5.3.3 Industrial

- 5.3.4 Other End-User Industries

- 5.4 By Country

- 5.4.1 Saudi Arabia

- 5.4.2 United Arab Emirates

- 5.4.3 South Africa

- 5.4.4 Other Regions in Middle East and Africa

6 COMPETITIVE LANDSCAPE

- 6.1 Company Profiles

- 6.1.1 Amcor PLC

- 6.1.2 MTS Medication Technologies

- 6.1.3 Constantia Flexibles GmbH

- 6.1.4 Sonoco Products Company

- 6.1.5 Klockner Pentaplast Group

- 6.1.6 Du Pont De Nemours and Company

- 6.1.7 Honeywell International Inc.

- 6.1.8 The Dow Chemical Company

7 INVESTMENT ANALYSIS

8 FUTURE OF THE MARKET