PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1851523

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1851523

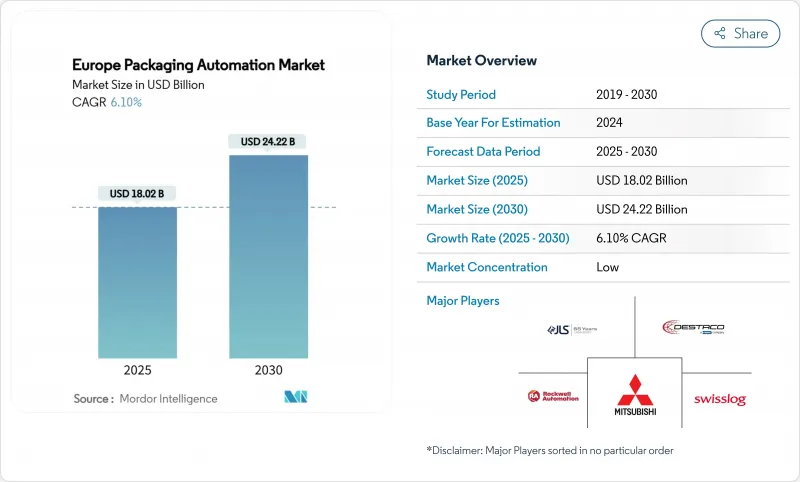

Europe Packaging Automation - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

The Europe Packaging Automation Market size is estimated at USD 18.02 billion in 2025, and is expected to reach USD 24.22 billion by 2030, at a CAGR of 6.10% during the forecast period (2025-2030).

Heightened regulatory demands, especially the EU Packaging and Packaging Waste Regulation (PPWR), converge with rising labor costs and rapid technological progress to re-shape capital-spending priorities across European manufacturing. Companies are automating to ensure recyclability compliance, close labor gaps and shield margins from energy-price swings. Line-side digitization, from AI-enabled inspection to cobot palletizing, is creating new competitive baselines. Simultaneously, end-users are widening supplier pools to mitigate raw-material volatility and cyber-risk exposure, thereby raising expectations for integrated, secure and upgradeable automation solutions. Intensifying buyer scrutiny around total cost of ownership favors vendors able to bundle hardware, analytics and life-cycle services into a single value proposition, accelerating consolidation among equipment makers and software specialists.

Europe Packaging Automation Market Trends and Insights

Pressure to Reduce Operating Costs

Packaging plants across Europe face sustained wage inflation and energy bills that remain well above 2022 levels, making automation the clearest path to offsetting operating pressure. ABB documented a 25% productivity gain at Striebel & John after deploying a multi-robot packaging island that also trimmed cardboard SKU counts from 15 to 9. Similar gains underpin Krones' 10.1% 2024 EBITDA margin, despite persistently high polymer prices, signalling that early adopters are widening their cost gap over late movers.

Shrinking Skilled-Labour Pool

Manufacturing employment in the EU fell 2.1% in 2024, with packaging-line technicians among the hardest roles to fill. Bosch Rexroth's battery-powered mobile cobot station lets one operator oversee tasks that previously needed a three-person team, freeing scarce labour for higher-value work. ABB's OmniVance plug-and-play cells further lower the expertise barrier by shipping pre-configured and self-calibrating, enabling SMEs to deploy robots without in-house programmers.

High Up-Front Capex

Turn-key robotic lines can demand EUR 5-10 million, a figure that still deters many mid-sized converters even after grants and tax incentives. Vendors are responding with subscription models that shift spend from capital budgets to OPEX, though long payback windows remain a hurdle for family-owned firms.

Other drivers and restraints analyzed in the detailed report include:

- EU Packaging-Waste and Traceability Mandates

- Mass-Customisation and Shorter SKUs

- Cyber-Security Vulnerabilities

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Manufacturers captured 41.5% of Europe packaging automation market share in 2024 by tying automation spend to overall plant-wide efficiency programs. Their scale supports multi-line roll-outs that amortize software and maintenance across higher volumes. Wholesale distributors adopt automation chiefly for palletising and cross-docking, whereas omni-channel retailers blend goods-to-person systems with automated bagging to accelerate fulfillment cycles. B2C e-commerce operators, buoyed by EUR 887 billion in regional online sales during 2024, will log a 13.0% CAGR to 2030, the fastest within the segment hierarchy. Investments gravitate toward smart sortation, auto-bagging and dimensioning modules capable of processing thousands of individualized parcels per hour. Personal-document shippers and contract packers remain niche but show steady uptake in track-and-trace capable printers and tamper-evident sealers.

A growing share of original manufacturers is revisiting make-versus-buy decisions, outsourcing secondary or tertiary packaging to co-packers yet retaining ownership of core filling and closing operations. That shift widens the addressable base for modular solutions that can be redeployed as order books fluctuate, ensuring vendors maintain recurring revenue from retrofits and line extensions.

Food and beverage control a combined 44.0% stake in the Europe packaging automation market, anchored by continuous-motion fillers, rotary cappers and wrap-around case packers optimized for high-volume SKUs. Coca-Cola's 2025 upgrades in Genshagen and Luneburg feature 60,000-container-per-hour glass lines, underscoring ongoing appetite for high-speed systems. Meanwhile the pharmaceutical sector, spurred by serialization and demand for personalized medicines, is expanding at 12.3% CAGR through 2030. Automated aggregation, inspection and cold-chain compliant palletizing are top investment areas, with Systech and ABB piloting multi-camera vision suites that certify every bundle before release.

Cosmetics and personal care brands adopt flexible cartoners and print-on-demand sleeve applicators to balance premium aesthetics with rising SKU counts. Household-chem and detergent makers focus on leak-proof dosing and space-saving secondary packs to navigate tightening transport-emission rules. Confectionery and bakery outfits deploy gentle-handling delta robots and ultrasonic bag sealers to preserve fragile products at speed, while 3PL providers scale up automated mailers and label applicators for omnichannel clients.

Europe Packaging Automation Market Report is Segmented by Business Type (Manufacturers, Wholesale Distributors, Omni-Channel Retailers and More), End-User Vertical (Food, Beverages, Pharmaceuticals, Cosmetics and Personal Care and More), Packaging Stage (Primary, Secondary, End-Of-Line, Tertiary & Intralogistics), Product Type (Filling Machines, Labelling and Coding, Form-Fill-Seal and More), and Geography.

List of Companies Covered in this Report:

- ABB

- Siemens AG

- Rockwell Automation

- Mitsubishi Electric

- Schneider Electric

- JLS Automation

- ULMA Packaging

- Swisslog Holding AG

- Gerhard Schubert GmbH

- Destaco

- Emerson (Branson)

- ATS Automation

- Massman Automation

- Krones AG

- Fanuc Corporation

- KUKA AG

- Coesia S.p.A.

- Syntegon Technology

- Sidel Group

- Yaskawa Electric

- Brenton Engineering

- Tetra Pak

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Pressure to Reduce Operating Costs

- 4.2.2 Shrinking Skilled-Labour Pool

- 4.2.3 EU Packaging-Waste and Traceability Mandates

- 4.2.4 Mass-Customisation and Shorter SKUs

- 4.2.5 AI-Enabled Predictive Maintenance

- 4.2.6 Plug-and-Play Modular Cobots

- 4.3 Market Restraints

- 4.3.1 High Up-Front Capex

- 4.3.2 Cyber-Security Vulnerabilities

- 4.3.3 Lack of Interoperability Standards

- 4.3.4 Raw-Material Supply Volatility

- 4.4 Regulatory Landscape

- 4.5 Technological Outlook

- 4.6 Porter's Five Forces Analysis

- 4.6.1 Bargaining Power of Suppliers

- 4.6.2 Bargaining Power of Buyers

- 4.6.3 Threat of New Entrants

- 4.6.4 Threat of Substitutes

- 4.6.5 Intensity of Rivalry

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Business Type

- 5.1.1 Manufacturers

- 5.1.2 Wholesale Distributors

- 5.1.3 Omni-channel Retailers

- 5.1.4 B2B e-Commerce Retailers

- 5.1.5 B2C e-Commerce Retailers

- 5.1.6 Personal-Document Shippers

- 5.1.7 Others

- 5.2 By End-User Vertical

- 5.2.1 Food

- 5.2.2 Beverages

- 5.2.3 Pharmaceuticals

- 5.2.4 Cosmetics and Personal Care

- 5.2.5 Household and Detergents

- 5.2.6 Chemical

- 5.2.7 Confectionery and Bakery

- 5.2.8 Warehousing and 3PL

- 5.2.9 Others

- 5.3 By Packaging Stage

- 5.3.1 Primary (Filling/Sealing)

- 5.3.2 Secondary (Cartoning/Case-Packing)

- 5.3.3 End-of-Line (Palletising/Stretch-Wrap)

- 5.3.4 Tertiary and Intralogistics

- 5.4 By Product Type

- 5.4.1 Filling Machines

- 5.4.2 Labelling and Coding

- 5.4.3 Form-Fill-Seal (H/VFFS)

- 5.4.4 Bagging and Pouching

- 5.4.5 Palletising and Depalletising

- 5.4.6 Others

- 5.5 By Geography

- 5.5.1 Germany

- 5.5.2 United Kingdom

- 5.5.3 France

- 5.5.4 Italy

- 5.5.5 Spain

- 5.5.6 Rest of Europe

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share, Products and Services, Recent Developments)

- 6.4.1 ABB

- 6.4.2 Siemens AG

- 6.4.3 Rockwell Automation

- 6.4.4 Mitsubishi Electric

- 6.4.5 Schneider Electric

- 6.4.6 JLS Automation

- 6.4.7 ULMA Packaging

- 6.4.8 Swisslog Holding AG

- 6.4.9 Gerhard Schubert GmbH

- 6.4.10 Destaco

- 6.4.11 Emerson (Branson)

- 6.4.12 ATS Automation

- 6.4.13 Massman Automation

- 6.4.14 Krones AG

- 6.4.15 Fanuc Corporation

- 6.4.16 KUKA AG

- 6.4.17 Coesia S.p.A.

- 6.4.18 Syntegon Technology

- 6.4.19 Sidel Group

- 6.4.20 Yaskawa Electric

- 6.4.21 Brenton Engineering

- 6.4.22 Tetra Pak

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-Need Assessment