Need help finding what you are looking for?

Contact Us

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1628827

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1628827

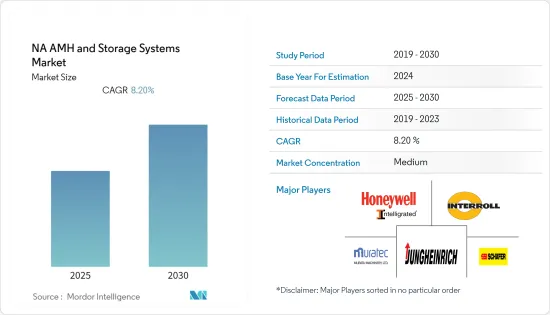

NA AMH and Storage Systems - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

PUBLISHED:

PAGES: 120 Pages

DELIVERY TIME: 2-3 business days

SELECT AN OPTION

The NA AMH and Storage Systems Market is expected to register a CAGR of 8.2% during the forecast period.

Key Highlights

- Vendors of material handling solutions gradually veered toward the modern approach of helping end-users focus on their operations' space and time utility by manufacturing flexible systems that can seamlessly integrate with other systems as part of the overall material handling plan. Also, automated guided vehicles and AS/RS have emerged as the most dynamic material handling equipment and storage systems solutions and are mainly deployed in warehouses, distribution centers, and airports.

- Further, various partnerships are witnessing in the North American Market. For instance, In February 2021, Best Buy, a prominent US-based consumer electronics store, announced redesigning its regional distribution centers in partnership with Bastian Solutions. The project included integrating automated storage and retrieval technology, conveyor, and warehouse execution software to serve each facility best. The association has assisted Best Buy in offering next-day delivery and managing large inbound shipments effectively.

- The focus on Industry 4.0 across different end-user industries in the region also presents new opportunities for the market. According to the 2021 Industry 4.0 survey by the BDO United States, almost 50% of the manufacturers anticipate their digital investments may lead to revenue increases in the next 12 months. Also, 43% of the respondents have deployed robotic process automation (RPA), while 47% plan to deploy it in the future. Some of the crucial aspects for improving the supply chain include customer order cycle (19%), total delivery cost (18%), performance to plan (18%), and inventory turnover (16%).

- Additionally, the increasing labor rates in the region are also developing the need for new technologies that help reduce the dependency on laborers for material handling. According to Statistics Canada, Labour costs per unit of output of Canadian businesses increased by 2.7% in the second quarter of 2021, following slight increases in the previous two quarters. The more rapid growth in unit labor costs primarily reflects the rebound in the average compensation per hour worked (+3.2%), following three-quarters of the decline.

North America AMH & Storage Systems Market Trends

Automated Guided Vehicle Expected to Witness Significant Market Share

- The growing adoption of Automated Guided Vehicles (AGVs) is also a factor that is driving the growth of the market. According to the Modern Materials Handling (MMH), 11% of the respondents will use AGVs in 2021, while 18% plan to use them in the next 24 months.

- The market is witnessing various innovations for automated tow and forklifts. For instance, In December 2020, Toyota announced a new Center-Controlled Rider and CoreTow Tractor Automated Forklifts for warehouse operations. The AGVs were developed by Toyota Forklift, in collaboration with Bastian Solutions, a subsidiary of Toyota Advanced Logistics company, for applications in manufacturing facilities and distribution center operations to perform highly repetitive tasks. Also, the new forklifts by Toyota operate manually whenever required and can work autonomously by utilizing light detection and ranging (LIDAR) based navigation.

- Also, the competitive environment among all the logistics players in the region encourages them to either increase their warehouse establishments or increase the efficiency of current warehouses establishments by automating the operations, which drives the use of automated guided vehicle growth in the market.

- Furthermore, the growth of large-scale warehouses is also presenting a need for automated forklifts, further driving the automated guided vehicle market. For instance, In November 2020, DSV Global Transport Logistics opened the largest Multi-Client Logistics Facility in Canada Near Toronto. The warehouse offers 111,000 sq. ft of climate-controlled space.

- The growing R&D in forklift technology is expected to create a scope for AGV, which is in line with the investments in Industry 4.0, artificial intelligence, and machine learning. Furthermore, COVID-19 has also increased consumer adoption and acceptance of e-commerce and created a need for remote material handling and storage systems in different end-user industries, which is also expected to create new opportunities for autonomous or driverless technologies in forklifts.

United States Expected to Witness Significant Market Share

- The United States is one of the significant robot markets worldwide, with sales being influenced by the demand from the automotive industry in the region. For instance, According to the World Robotics 2020 Industrial Robots report presented by the International Federation of Robotics (IFR), a record of about 293,000 industrial robots operating in factories of the United States an increase of 7% compared with the previous year. Sales of new robots remain on a high level, with 33,300 units shipped in 2019. The growth in robotics technology creates new opportunities for the market.

- The growing warehouse space in the region is also developing a need for automated material handling and storage equipment. According to the Bureau of Labor Statistics, warehouses increased from 18,736 in 2019 to 19190 in 2020. Furthermore, companies such as Amazon and Walmart are expanding their footprint rapidly with new warehouses. In May 2021, Amazon announced a 3.8 million square feet warehouse, one of the country's largest warehouses.

- The investments in mobile robotics, artificial intelligence, and machine learning are also driving the country's growth. For instance, The National Robotics Initiative 3.0 2021 focuses on accelerating the development and use of robots in the United States.

- According to the 2020 Honeywell Intelligrated Automation Investment Study, more than half of the companies in the United States are increasingly open to investing in automation to survive changing market conditions. The industries that are most willing to invest in automation are e-commerce (60%), grocery, food, and beverage (59%), and logistics (55%). Thus, creating new opportunities for the adoption of automated material handling and storage systems.

- The increase in warehouse automation, rising adoption of automated material handling, and trends, like lights-out automation, are some of the major factors driving the United States.

North America AMH & Storage Systems Industry Overview

The North America Automated Material Handling and Storage Systems Market is moderately competitive, with a considerable number of regional and global players. The major vendors with a prominent share in the market are focusing on innovations, mergers and acquisitions, partnerships, and expanding customer base across foreign countries. The companies are leveraging on strategic collaborative initiatives to increase their profitability.

- August 2020 - Murata Machinery Ltd signed a contract with Alpen Co. Ltd to construct the first 3D robot warehousing system, ALPHABOT. Further, ALPHABOT will be introduced at the Alpen Komaki Distribution Center, one of Alpen Group's main distribution centers, to complement its storage capacity and reduce picking, sorting, and packaging operations by approximately 60%.

- July 2020 - Interroll completed construction of the second plant in Hiram (Atlanta), Georgia. The USD 11 million investment gives Interroll a substantial increase in capacity for the region. At Interroll, the Americas region continues to see a high level of project activities. At the same time, the company is quickly introducing innovative solutions to the markets.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

Product Code: 55098

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Consumers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Impact of COVID-19 on the Industry Ecosystem

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Increasing Technological Advancements Aiding Market Growth

- 5.1.2 Rapid Growth in E-commerce Leading to Warehouse Automation

- 5.1.3 Industry 4.0 Investments Driving the Demand for Automated Material Handling and Storage Systems

- 5.2 Market Challenges

- 5.2.1 Unavailability for Skilled Workforce

- 5.2.2 High Capital Requirements

6 MARKET SEGMENTATION

- 6.1 By Product Type

- 6.1.1 Software

- 6.1.2 Hardware

- 6.1.3 Services

- 6.1.4 Integration

- 6.2 By Equipment Type

- 6.2.1 Mobile Robots

- 6.2.1.1 Automated Guided Vehicle(AGV)

- 6.2.1.1.1 Automated Forklift

- 6.2.1.1.2 Automated Tow/Tractor/Tug

- 6.2.1.1.3 Unit Load

- 6.2.1.1.4 Assembly Line

- 6.2.1.2 Autonomous Mobile Robots(AMR)

- 6.2.2 Automated Storage and Retrieval System(ASRS)

- 6.2.2.1 Fixed Asile

- 6.2.2.2 Carousel

- 6.2.2.3 Vertical Lift Module

- 6.2.3 Automated Conveyor

- 6.2.3.1 Belt

- 6.2.3.2 Roller

- 6.2.3.3 Pallet

- 6.2.3.4 Overhead

- 6.2.4 Palletizer

- 6.2.4.1 Conventional

- 6.2.4.2 Robotic

- 6.2.5 Sortation System

- 6.2.1 Mobile Robots

- 6.3 By End-User

- 6.3.1 Airport

- 6.3.2 Automotive

- 6.3.3 Food and Beverage

- 6.3.4 Retail/Warehousing/Distribution Centers/Logistic Centers

- 6.3.5 General Manufacturing

- 6.3.6 Pharmaceuticals

- 6.3.7 Post and Parcel

- 6.3.8 Electronics and Semiconductor Manufacturing

- 6.3.9 Other End-Users

- 6.4 By Country

- 6.4.1 United States

- 6.4.2 Canada

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 JBT Corporation

- 7.1.2 Honeywell Intelligrated (Honeywell International Inc.)

- 7.1.3 SSI SCHEFER AG

- 7.1.4 Daifuku Co. Limited

- 7.1.5 Kardex Group

- 7.1.6 Beumer Group GMBH & Co. KG

- 7.1.7 Jungheinrich AG

- 7.1.8 Murata Machinery Limited

- 7.1.9 TGW Logistics Group GmbH

- 7.1.10 Witron Logistik

- 7.1.11 System Logistics

- 7.1.12 Interroll Group

8 INVESTMENT ANALYSIS

9 FUTURE OF THE MARKET

Have a question?

SELECT AN OPTION

Have a question?

Questions? Please give us a call or visit the contact form.