PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1627212

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1627212

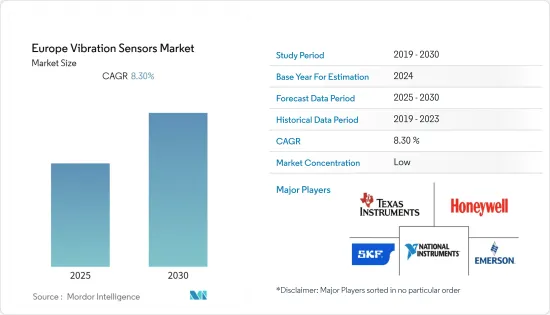

Europe Vibration Sensors - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

The Europe Vibration Sensors Market is expected to register a CAGR of 8.3% during the forecast period.

Key Highlights

- The customization in the vibration sensor is growing with respect to its size, load capacity, and frequency range. They are designed to pinpoint engine problems and eliminate unnecessary engine removals quickly.

- The sensing capabilities with respect to sensors and it's usage reduce with its end-user application. The restraints are technical; response time in analyzing the vibration can't be detected due to heavy signal load.

- The European vibration sensor market has experienced important developments over the past decade resulting in a wide variety of innovative and technologically superior products.

- There has been an increase in demand for a variety of sensors to perform a multitude of functions as vehicles have become more complex over the last five years. Continued growth is anticipated for this market, propelled by enhanced demand for greater driver information, tighter safety controls, and more sophisticated engine management systems to improve fuel economy and reduce emissions. The Europe Vibration Sensors market is comprised of mostly large global corporations with few small market participants.

Europe Vibration Sensors Market Trends

Aerospace & Defense End User to Hold Significant Share

- An increase in situational awareness to drive operations, cost-effective maintenance, and increase in asset utilization are some of the key factors driving the demand for aircraft health monitoring systems.

- The passenger traffic in Europe and other major aviation markets, such as the United Kingdom and Germany, have witnessed growth in terms of the number of passengers and aircraft movements, which is expected to drive the market during the forecast period.

- Turbine engine failures are the primary cause of mechanical failures, which is increasing the costs; hence, users are increasingly turning to prognostic health management (PHM) systems to prevent these losses and to reduce maintenance costs. As vibration is the most common health monitoring parameter in the aerospace engine industry, the development of PHM systems is likely to have a direct impact on the growth of vibration sensors.

Growing Adoption of Industrial IOT in Europe Region

- Over the last decade, IoT solutions have been increasingly adopted for optimizing discrete manufacturing products and environments. Discrete manufacturers (in automotive, industrial machinery), along with process manufacturers, face intense competition. Hence, they are increasingly investing in new technologies that leverage the capabilities of IoT, cloud, and Big Data analytics to enhance their ability to innovate maximize return on their assets.

- With the advent of Industry 4.0, trends, like Industrial IoT (IIoT), smart manufacturing, smart factory, predictive manufacturing, industrial robots, sensors, have made IoT the central backbone of these discrete and process manufacturing environments enabling remote monitoring, continuously scanning capabilities from the equipment on the factory floor, real-time analysis, and supporting new capabilities, such as predictive maintenance.

- Industry 4.0 is aiding the industries' transition from having legacy systems to smart components and smart machines, facilitating digital factories, and later, to an ecosystem of connected plants and enterprises.

- With the smart factory concept coming into force, companies focus on predictive maintenance and manufacturing, which is anticipated to reduce maintenance costs and enhance production capacities. According to the US Department of Energy, predictive maintenance is highly cost-effective, saving roughly 8% to 12% over preventive maintenance and up to 40% over reactive maintenance. Therefore, to improve manufacturing safety and performance, many manufacturing organizations have added condition-based (predictive) maintenance approaches to their maintenance strategies.

- Moreover, according to Wollenhaupt, low maintenance strategies can reduce a company's production capacity by as much as 20%. To identify the problems and prevent them, machine conditioning equipment is one of the most effective maintenance tools.

- This drive for predictive maintenance has driven the technologies, components, and equipment supporting it, thereby augmenting the market's vibration sensors.

Europe Vibration Sensors Industry Overview

The European vibration sensor market is highly fragmented. The presence of global sensor manufacturers with established brand identities in the market is expected to have a profound influence on the intensity of competitive rivalry, as new entrants face challenges in reaching out to consumers. Brand identity plays a strong role in determining buyer behavior. Therefore, well-known companies have a considerable advantage over other players in the market. Some of the key players are Texas Instruments, Honeywell, and Emerson.

- June 2020 - National Instruments Corporations unveiled an updated brand identity, including a new logo, visual identity, enhanced digital experiences, and a brand campaign. Now known simply as NI, it is modernizing the test and measurement industry by coupling its rich software heritage with new cloud and machine learning capabilities.

- April 2020 - Emerson acquired the leading hydroelectric turbine controls company, American Governor Company. The addition of American Governor Company builds on Emerson's technology capabilities and expertise in the renewable and power industry

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition'

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Dyanmics

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Increasing Need for Machine Monitoring and Maintenance

- 4.2.2 Longer Service Life, Self Generating Capability and Wide Range of Frequency of Vibration Sensors

- 4.3 Market Restraints

- 4.3.1 Compatibility With Old Machinery

- 4.3.2 Critical and Hazardous Implication on the Environment

- 4.4 Industry Attractiveness - Porter's 5 Forces

- 4.4.1 Threat of New Entrants

- 4.4.2 Threat of Substitute Products or services

- 4.4.3 Bargaining Power of Suppliers

- 4.4.4 Bargaining Power of Buyers

- 4.4.5 Intensity of competitive rivalry

- 4.5 Industry Value chain analysis

5 Technology Snapshot

- 5.1 Type of Technology

- 5.1.1 Inductive

- 5.1.2 Piezoelectric

- 5.1.3 Magnetic

- 5.1.4 Capacitive

- 5.1.5 Optic Fiber Sensor

6 Europe Vibration sensors market segmentation

- 6.1 By product

- 6.1.1 Accelerometers

- 6.1.2 Proximity Probes

- 6.1.3 Tachometers

- 6.1.4 Others

- 6.2 By Industry

- 6.2.1 Automotive

- 6.2.2 Helathcare

- 6.2.3 Aerospace & Defence

- 6.2.4 Consumer Electronics

- 6.2.5 Oil And Gas

- 6.2.6 Metals and Mining

- 6.2.7 others

- 6.3 By Country

- 6.3.1 United Kingdom

- 6.3.2 Germany

- 6.3.3 France

- 6.3.4 Others

7 Competitive Landscape

- 7.1 Company Profiles

- 7.1.1 SKF AB

- 7.1.2 National Instruments Corporation

- 7.1.3 Texas Instruments Incorporated

- 7.1.4 Analog Devices Inc.

- 7.1.5 Rockwell Automation Inc.

- 7.1.6 Emerson Electric Co

- 7.1.7 Honeywell International Inc.,

- 7.1.8 NXP Semiconductors N.V.

- 7.1.9 TE Connectivity Ltd.

- 7.1.10 Hansford Sensors Ltd.,

- 7.1.11 Bosch Sensortec GmbH (Robert Bosch GmbH)

8 Investment Outlook

9 Future of Europe Vibration Sensors Market