Need help finding what you are looking for?

Contact Us

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1627126

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1627126

Latin America Process Automation - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

PUBLISHED:

PAGES: 120 Pages

DELIVERY TIME: 2-3 business days

SELECT AN OPTION

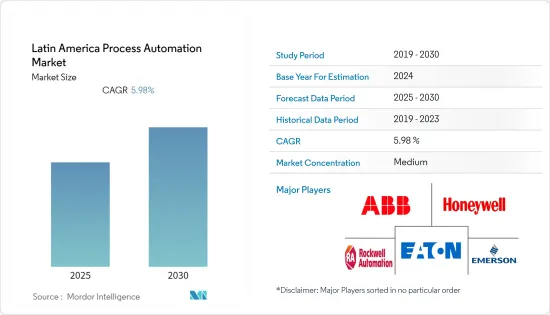

The Latin America Process Automation Market is expected to register a CAGR of 5.98% during the forecast period.

Key Highlights

- Automation has become an essential part of modern manufacturing and industrial processes. It helps enterprises to realize the priorities above. Companies worldwide are automating their operations with the help of different technologies like SCADA, DCS, MES, and PLC. The demand for these technologies is escalating, and many vendors are manufacturing solutions to help enterprises achieve higher efficiency in their manufacturing processes.

- The IoT demand trend is expected to shift toward industrial space from consumer demand over the near future, primarily driven by various Industry 4.0 applications. Countries like Mexico and Brazil are on the verge of the industrial revolution, as data is being used on a large scale for production while integrating it with various manufacturing systems throughout the supply chain.

- Moreover, big data analytics allows an enterprise to use factory automation to shift from reactionary practices to predictive ones. This change targets to improve the efficiency of the process and performance of the product.

- Automation of manufacturing processes has offered various benefits, such as effortless monitoring, reduction of waste, and production speed. This technology offers customers an improved quality with standardization and dependable products within time and at a much lower cost.

- Further, connecting the industrial machinery and equipment and obtaining real-time data have played a vital role in the adoption of SCADA, HMI, PLC systems, and software that offer visualization; thus enables reducing the faults in the product, reducing downtime, scheduling maintenance, and switching from being in the reactive state to predictive and prescriptive stages for decision-making.

Latin America Process Automation Market Trends

Pharmaceutical Industry is Expected to Hold Significant Market Share

- The pharmaceutical industry is highly regulated due to the importance placed on public health safety. Accuracy, repeatability, and control are the key benefits of an automated system, helping to enhance productivity, safety, and cleanliness in pharmaceutical manufacturing facilities. The need for process optimization, regulatory compliance, and enhancements in the supply chain are driving investment in automation technologies across the pharmaceutical industry.

- Automation is embedded in primary aspects such as Active Pharma Ingredients (API) and other secondary aspects, including packaging and distribution. Digital transformation provides new operational efficiency, quality, process automation, and employee productivity to pharmaceutical companies in the region.

- Moreover, an increase in the need for process automation solutions to various processes such as manufacturing, testing, drug development, packaging, and distribution are among the factors that are likely to propel the growth in the pharmaceutical industry in the process automation and instrumentation market.

- Automation offers better control of processes and the ability to monitor processes from remote locations. It assists in automatically creating reports, entering essential data, and sharing real-time information. Automation is transforming pharma concerning product development, commercial production, and real-time monitoring. It can foster manufacturing excellence by adopting sensors and systems to help companies achieve compliance at the lowest costs.

- Further, many pharma companies in Latin America have mobilized their employees to remote working conditions. In such a scenario, automation helps them continue the essential processes unobstructed. Automation in drug discovery enhances the reliability of the entire process by minimizing manual errors, augments the throughput, and improves the ability to reproduce.

Mexico Accounts for the Largest Market Share

- IoT solutions in Latin America, specifically Mexico, have grown from servicing the supply chain process to adding visibility to healthcare, government offices, and hospitality industries. The rapidly growing implementation of Wi-Fi, RFID, Bluetooth, and sensors have brought on the IoT revolution, which is believed to be the most transformative technology for the next decade by 99% of respondents.

- The increasing demand for connected and wearables devices is also aiding the growth of the market in the country. With the high rate of adoption of connected devices and sensors and the enabling of M2M communication, there has been a surge in the data points generated in the manufacturing industry.

- The IoT demand trend is expected to shift toward industrial space from consumer demand over the near future, primarily driven by various Industry 4.0 applications. Furthermore, process industries, such as chemical and petrochemical, paper and pulp, water and wastewater treatment, energy and utilities, oil and gas, pharmaceutical, food, and beverages, are expected to fuel growth. Similar trends were observed in the Latin American market as well.

- With cyber-attacks increasing in smart factories in Mexico, there is growing concern about using Industrial Control Systems. The government has plans to curb the rise of such crimes. This aligns with the growing trend of industrial control systems manufactured in the country for smart factories to avoid the risk of cybersecurity breaches.

- Further, technologies and terminologies such as process discovery, process optimization, process intelligence, and process orchestration are becoming a more significant part of Robotic Process Automation (RPA). There is an ongoing trend of increasing a closer relationship between business process management (BPM) and RPA in the future.

Latin America Process Automation Industry Overview

The Latin American Process Automation Market is moderately fragmented, with few new entrants and few dominant players. The companies keep on innovating and entering into strategic partnerships to retain their market share. Some of the recent developments in the market are:

- July 2021 - Rockwell Automation, Inc announced a partnership with Kezzler AS, cloud-based product digitization and traceability platform, to help manufacturers capture the journey of their products from raw material sources to point-of-sale or beyond using cloud-based supply chain solutions that focus on product traceability.

- May 2020 - OleumTech, wireless industrial automation and IoT solutions provider announced the launch of new intelligent pressure transmitters (HGPT Smart Gauge Pressure Transmitters). These transmitters are an addition to its fast-growing H Series line of hardwired process instrumentation and claimed to deliver remarkable performance, accuracy, and reliability ideal for process industries, such as petrochemical, chemical, power, upstream oil, and gas wastewater.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

Product Code: 49570

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHADOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Industry Value Chain Analysis

- 4.4 Market Drivers (Growing emphasis on energy efficiency & cost reduction| Demand for Safety Automation Systems| Emergence of IIoT)

- 4.5 Market Challenges (Cost & Implementation Challenges)

- 4.6 Industry Standards & Regulations

- 4.7 Analysis of the major Industrial Automation hubs in the Mexico, Brazil, and Argentina - To be identified based on the investor activity & expansion activities undertaken over the last 3 years

5 ASSESSMENT OF THE IMPACT OF COVID-19 ON THE PROCESS AUTOMATION INDUSTRY IN LATIN AMERICA

- 5.1 Analysis of the key themes identified based on the near & medium-term effects of the pandemic - V-shaped recovery, Mid-range recovery & Slump recovery

- 5.2 Mexico Process Automation Market - Base variable analysis based on end-user performance

- 5.3 Brazil Process Automation Market - Base variable analysis based on end-user performance

- 5.4 Argentina Process Automation Market - Base variable analysis based on end-user performance

- 5.5 Impact of Supply-related challenges & the role of market regulations in spurring activity

6 MARKET SEGMENTATION

- 6.1 By Communication Protocol

- 6.1.1 Wired

- 6.1.2 Wireless

- 6.2 By System Type

- 6.2.1 By System Hardware

- 6.2.1.1 Supervisory Control and Data Acquisition System (SCADA)

- 6.2.1.2 Distributed Control System (DCS)

- 6.2.1.3 Programmable Logic Controller (PLC)

- 6.2.1.4 Manufacturing Execution System (MES)

- 6.2.1.5 Valves & Actuators

- 6.2.1.6 Electric Motors

- 6.2.1.7 Human Machine Interface (HMI)

- 6.2.1.8 Process Safety Systems

- 6.2.1.9 Sensors and Transmitters

- 6.2.2 By Software Type

- 6.2.2.1 APC (Standalone & Customized Solutions)

- 6.2.2.1.1 Advanced Regulatory Control

- 6.2.2.1.2 Multivariable Model

- 6.2.2.1.3 Inferential & Sequential

- 6.2.2.2 Data Analytics and Reporting-based Software

- 6.2.2.3 Other Software and Services

- 6.2.1 By System Hardware

- 6.3 By End-user Industry

- 6.3.1 Oil and Gas

- 6.3.2 Chemical and Petrochemical

- 6.3.3 Power and Utilities

- 6.3.4 Water and Wastewater

- 6.3.5 Food and Beverage

- 6.3.6 Paper and Pulp

- 6.3.7 Pharmaceutical

- 6.3.8 Other End-user Industries

- 6.4 By Country

- 6.4.1 Mexico

- 6.4.2 Brazil

- 6.4.3 Argentina

- 6.4.4 Rest of the Latin America

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 ABB Ltd

- 7.1.2 Honeywell International Inc.

- 7.1.3 Rockwell Automation

- 7.1.4 Emerson Electric Co.

- 7.1.5 Eaton Corporation

- 7.1.6 Siemens AG

- 7.1.7 Schneider Electric

- 7.1.8 General Electric Co.

- 7.1.9 Mitsubishi Electric

- 7.1.10 Fuji Electric

- 7.1.11 Delta Electronics Limited

- 7.1.12 Yokogawa Electric

8 ANALYSIS OF MAJOR INNOVATORS & CHALLENGERS IN THE PROCESS AUTOMATION INDUSTRY

9 INVESTMENT ANALYSIS & MARKET OUTLOOK

Have a question?

SELECT AN OPTION

Have a question?

Questions? Please give us a call or visit the contact form.