PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1550033

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1550033

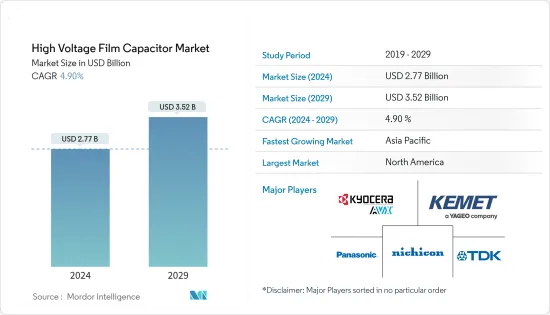

High Voltage Film Capacitor - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029)

The High Voltage Film Capacitor Market size is estimated at USD 2.77 billion in 2024, and is expected to reach USD 3.52 billion by 2029, growing at a CAGR of 4.90% during the forecast period (2024-2029).

The market for high-voltage film capacitors is witnessing growth due to the increasing adoption of renewable energy sources, such as wind and solar power, which require efficient energy storage and conversion systems. High-voltage film capacitors are crucial in these systems for their stability, long lifespan, and high voltage tolerance. Additionally, the demand for electric vehicles, power transmission and distribution, and the continuous improvements in capacitor technology are some of the factors that are driving market growth.

Key Highlights

- High-voltage film capacitors are electrical components that store and release electrical energy at high voltage levels. They are constructed using thin plastic films as the dielectric material sandwiched between metal electrodes. These capacitors are known for their high insulation resistance, stability, and ability to handle high-voltage applications without significant performance degradation.

- High-voltage film capacitors are favored for their high performance, durability, and ability to withstand harsh conditions, making them indispensable in a wide range of high-voltage and high-power applications.

- High-voltage film capacitors are known for their self-healing properties, which allow them to recover from partial dielectric breakdown. In metalized film capacitors, when a dielectric breakdown occurs, the thin metal layer around the breakdown evaporates, isolating the fault and allowing the capacitor to continue functioning.

- The increasing modernization of power grids and the expansion of high-voltage direct current (HVDC) transmission systems are driving the demand for these capacitors, as they help improve the efficiency and reliability of power transmission over long distances. According to the IEA (International Energy Agency), the world electricity demand is anticipated to increase by nearly 80% between 2012 and 2040. Expansion, modernization, digitization, and decentralization of the electricity infrastructure for improved resiliency and a planned investment from organizations such as the World Economic Forum (USD 7.6 trillion allocated for smart grids for the next 25 years) are expected to change various market dynamics in the global scenario.

- Further, utilities worldwide are increasingly adopting technologies like artificial intelligence and digital twinning, coupled with increased government support and initiatives, which are further attracting investments in smart grid projects. For instance, in January 2024, the US Department of Energy announced the development of technologies aimed at modernizing the electric grid, undergrounding power lines, and replacing aging infrastructure with USD 34 million in grants. The program is aimed at advancing solutions to modernize and boost the country's power grid infrastructure by minimizing extreme weather-related disruptions, lowering costs, and accelerating the adoption of renewable energy.

- The impact of macroeconomic factors such as supply chain disruptions, energy prices, sanctions, trade restrictions, and rising inflation, along with the Russia-Ukraine War, has created a challenging environment for the high-voltage film capacitor market. While disruptions and cost increases pose significant challenges, the ongoing push for renewable energy and electric vehicles continues to drive demand, providing some counterbalance to the negative factors.

High Voltage Film Capacitor Market Trends

Automotive Segment is Expected to Witness a Significant Growth Rate

- High-voltage film capacitors play a crucial role in the automotive industry, particularly in electric vehicles, hybrid electric vehicles, and advanced internal combustion engine vehicles. These capacitors are integral in power electronics systems that manage vehicles' flow and conversion of electrical energy.

- In EVs and HEVs, battery management systems use high-voltage film capacitors to stabilize voltage and manage the battery's charging and discharging cycles. This ensures the battery pack's optimal performance and longevity.

- Further, the increasing initiatives for adopting ABS and ADAS are further boosting the segment's growth. As vehicles become more advanced with ADAS features, the power requirements increase. High-voltage film capacitors help manage these power needs, providing stable and reliable power to sensors and processors that enable ADAS functionalities.

- The Indian government has been actively promoting the adoption of ADAS through various regulations and policies. Initiatives to mandate certain ADAS features in new cars are anticipated, mirroring global trends. This regulatory push is likely to accelerate the widespread adoption of these technologies.

- Further, Automotive Industry Standard 145 requires every vehicle sold in India to have airbags, SBR, ABS, and SWS. The recently introduced AIS 197: BNCAP (Bharat New Car Assessment Program), with its stricter crash testing norms, is expected to catalyze the uptake of passive and active safety, laying the groundwork for ADAS becoming a mandatory requirement.

Asia-Pacific is Expected to Witness Significant Market Growth

- Industrial expansion, renewable energy projects, transportation electrification, consumer electronics growth, smart grid development, technological advancements, supportive government policies, and increasing energy demand propel the growth of high-voltage film capacitors in Asia-Pacific.

- China has been one of the world's largest automotive markets for the past years and is becoming a powerhouse for automotive technology. The country may considerably impact the automotive industry in the coming years as it is open to technological progress. Moreover, with the arrival of Industry 4.0, China is expected to see massive growth in the automation and industry sector, owing to schemes like "Made in China 2025."

- Further, in January of this year, China's BYD outpaced Tesla in becoming the world's largest producer of pure-electric vehicles. The surge is fuelled by rising EV demand in China, where 40% of vehicles sold are electric. This shift toward electric vehicles and the development of electric public transportation systems in Asia-Pacific are driving the demand for high-voltage film capacitors.

- The consumer electronics and telecommunication industries in India are also witnessing significant growth. These industries are expected to create a favorable market scenario for the development of the country's high-voltage film capacitor market. According to ICEA, India can achieve a value of USD 100 billion in the manufacturing of laptops and tablets by 2025. Furthermore, according to IBEF, the Indian appliances and consumer electronics industry is expected to more than double to reach USD 21.18 billion.

- Further, the Indian telecom tower industry has grown significantly by 65% over the past seven years. FDI in the telecommunication sector during 2022-2023 was USD 694 million compared to USD 668 million during 2021-2022.

High Voltage Film Capacitor Industry Overview

The high-voltage film capacitor market is highly competitive, with several vendors of different sizes. As organizations continue to invest strategically in offsetting the present slowdowns, the market is anticipated to encounter a number of partnerships, mergers, and acquisitions. The key companies operating in the market include TDK Corporation, KYOCERA AVX, Kemet Corporation, and Vishay Intertechnology.

- April 2024: Kyocera AVX released two new snap-in aluminum electrolytic capacitors series. The SNA and SNL Series deliver high reliability, high voltage, and high CV performance over long lifetimes. In addition, both series are lead-free compatible and RoHS compliant, rated for temperatures extending from -25°C to +105°C, and ideal for use in commercial and industrial applications, including frequency converters, solar inverters, power inverters, energy storage systems, and power supplies.

- April 2024: KEMET Corporation announced launching the R41P, a Y2/X1 film capacitor whose smaller size (40% smaller than the R41T) is particularly impressive in applications where space requirements and costs are prioritized. Accordingly, the component has a lower THB value and a shorter service life at high temperatures. This capacitor series is suitable for use in filters for suppressing electromagnetic interference (EMI) in "line-to-ground" and "across-the-line" applications that require safety classification Y2/X1.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumption and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Threat of New Entrants

- 4.2.2 Bargaining Power of Buyers/Consumers

- 4.2.3 Bargaining Power of Suppliers

- 4.2.4 Threat of Substitute Products

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Industry Value Chain Analysis

- 4.4 Impact of COVID-19 Aftereffects and Other Macroeconomic Factors on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Growing Demand for Electric Vehicles

- 5.1.2 Rising Demand for Smart Grids

- 5.1.3 Increasing Demand for Energy Efficient Technologies

- 5.2 Market Restraints

- 5.2.1 Limited Availability of Raw Materials

- 5.2.2 High Production Cost

6 ANALYSIS OF WOUND TYPE AND LAMINATE TYPE

7 MARKET SEGMENTATION

- 7.1 By End-user Industry

- 7.1.1 Automotive

- 7.1.2 Aerospace and Defense

- 7.1.3 Oil and Gas

- 7.1.4 Drives and Inverters (Non-automotive)

- 7.1.5 Other End-user Industries

- 7.2 By Geography

- 7.2.1 North America

- 7.2.2 Europe

- 7.2.3 Asia-Pacific

- 7.2.4 Australia and New Zealand

- 7.2.5 Latin America

- 7.2.6 Middle East and Africa

8 COMPETITIVE LANDSCAPE

- 8.1 Company Profiles

- 8.1.1 TDK Corporation

- 8.1.2 KYOCERA AVX Components Corporation

- 8.1.3 Nichicon Corporation

- 8.1.4 Kemet Corporation

- 8.1.5 Panasonic Industry Co. Ltd

- 8.1.6 Vishay Intertechnology nc.

- 8.1.7 WIMA GmbH & Co. KG

9 MARKET OUTLOOK