PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1692475

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1692475

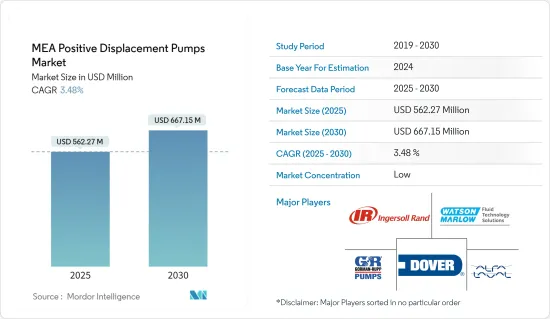

MEA Positive Displacement Pumps - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

The MEA Positive Displacement Pumps Market size is estimated at USD 562.27 million in 2025, and is expected to reach USD 667.15 million by 2030, at a CAGR of 3.48% during the forecast period (2025-2030).

Positive displacement pumps are used for pumping high-viscosity fluids, including oil, paints, resins, or foodstuffs. They are selected in applications where accurate dosing or high-pressure output is required. Unlike centrifugal pumps, the production of a positive displacement pump is not affected by pressure. Thus, they are also likely to be preferred in any situation where the supply is irregular.

To evaluate the market revenue for the Middle East & African positive displacement market, the sales of positive displacement pumps across the Middle East & Africa have been tracked. Different types of pumps are considered in the report, including diaphragm, piston, gear, lobe, progressive, screw, vane, and peristaltic, which are used in multiple end-user industries like oil and gas, chemicals, food and beverage, water and wastewater, pharmaceuticals, power generation, among others. The competitive landscape has been taken to calculate positive displacement pump penetration and how players involve themselves in organic and inorganic growth strategies.

A positive displacement pump operates by trapping a set amount of water and pushing it into the discharge piping. Some models of positive displacement pumps feature an expanding cavity on the suction side and a shrinking cavity on the discharge side. Positive displacement pumps are known for their operation of trapping a fixed volume of fluid in a cavity and then pushing that fluid into the discharge pipe. On the other hand, centrifugal pumps transfer the motor's kinetic energy to the liquid through a spinning impeller, which draws in fluid and increases velocity to move the liquid to the discharge point.

Positive displacement pumps are integral to various oil and gas operations stages, including exploration, extraction, refinement, and distribution. These pumps are crucial for handling high-viscosity fluids and providing consistent flow rates, which make them suitable for critical applications in the oil and gas sector. The ability of these pumps to work at lower speeds reduces the risk of damage when handling high-viscosity oils and slurries, further enhancing their utility in the industry.

The high initial investment required for positive displacement pumps is a significant barrier to market growth. These pumps are often more expensive than other types, which can deter potential buyers, especially small and medium-sized enterprises. In addition, the difficulty of maintaining these pumps further adds to the overall cost, affecting their sales and market penetration.

The swift growth of civic water utility infrastructure in emerging regions like the Middle East & Africa has resulted in a higher need for positive displacement pumps. There has been a significant rise in the demand for sewage treatment in both the public and industrial sectors, leading to an increased installation of pumping units. Implementing technologies such as desalination and zero-liquid discharge (ZLD) is anticipated to further drive the market for positive displacement pumps in civic and industrial sectors.

MEA Positive Displacement Pumps Market Trends

Growth in the Construction Sector Boosting the Demand for Furniture Products

- The diaphragm pump, also called an AODD (Air Operated Double Diaphragm), is a type of double diaphragm positive displacement pump operated using compressed air. Diaphragm pumps utilize a pneumatic valve to alternate compressed air between the pump's two sides. They excel at managing liquids of diverse viscosities, including those with suspended solids. This type of pump, due to its design configurations and type of materials used, is also capable of safely and efficiently handling particularly aggressive chemicals.

- The diaphragm pump is positioned above the fluid level and can aspirate it, even starting from dry when it has no liquid inside. The distance between the pump and the fluid level results in loss loads. If the pump is not potted, the maximum height at which the fluid can be aspirated cannot exceed 6 m, while if the pump is potted, we can reach 9.5 m.

- In some applications, two fluids need to be pumped, but there is not enough room to accommodate two separate pumps. Various companies offer the opportunity to customize their pumps by splitting both delivery and suction. This means that with the same pump, customers can pump two fluids, for example, of two different colors. The fluids, however, need to have similar viscosity and density characteristics.

- The growing demand in water and wastewater treatment, oil and gas, food and beverage, and pharmaceutical industries is a significant driver of market growth. For instance, in Kuwait, hydrocarbons contribute 50% of its GDP, with oil accounting for approximately 90% of export earnings and fiscal revenues. Kuwait planned to increase its oil production capacity to 4.0 million barrels per day by 2035 and gas capacity to 42.5 million cubic meters per day by 2040. KPC aims for net zero by 2050, presenting opportunities in the energy transition. Kuwait intends to invest USD 48 billion in exploration and drilling over the next five years to expand its oil production from existing and mature oil fields.

Asia-Pacific is Expected to Hold Significant Market Share

- Saudi Arabia is one of the world's largest producers and exporters of oil and gas. It plays a significant role in shaping the market's demand for positive displacement pumps. The country's oil and gas industry, driven by its vast reserves and strategic initiatives, demands various equipment and technologies, including positive displacement pumps.

- The Government of Saudi Arabia has been actively investing in the oil and gas sector, identifying new oil fields, expanding existing fields, and enhancing production. These investments contribute to the growth of the oil and gas industry in the region and subsequently drive the demand for PD pumps.

- In November 2023, Saudi Aramco unveiled two fresh natural gas finds in the Empty Quarter region. The Al-Hiran gas field's discovery was solidified as it exhibited a flow rate of 30 million standard cubic feet per day, accompanied by 1,600 barrels of condensate daily. Similarly, the Al-Mahakik gas field's presence was affirmed as gas emanating at 0.85 million standard cubic feet. In February 2024, Saudi Aramco found an additional 15 Tcf of natural gas and 2 billion barrels of condensate in the onshore Jafurah unconventional field as the world's biggest oil exporter pushes ahead with efforts to expand gas production.

- Saudi Arabia's 2030 Vision calls for leveraging the Kingdom's location, strategic partnerships, energy sources, and logistics to stimulate a new phase of industrialization and automation in the country. It also aims to bring manufacturing half of the Kingdom's military needs within the Kingdom by 2030 and to automate the Kingdom's renewable energy and industrial manufacturing sector.

- In 2023, the Ministry of Environment, Water and Agriculture (MEWA) announced that it would allocate USD 80 billion to water projects within the coming years. This aligns with the United Nations Sustainable Development Goals (SDGs), which aim to enable equal access to clean and safe water globally.

- MEWA aims to satisfy 90% of Saudi Arabia's water demand through desalination by 2030, with the remaining 10% sourced from ground and surface water. To bridge the projected water deficit of 4.5 million m3/day, new urban desalination facilities are deemed necessary, aligning with the current urban water needs and the assured water supply.

MEA Positive Displacement Pumps Industry Overview

The MEA positive displacement pumps market is highly fragmented, with the presence of major players like Dover Corporation, Ingersoll Rand Inc., Watson-Marlow Fluid Technology Solutions (Spirax Group PLC), Alfa Laval AB, and Gorman-Rupp Corporation (Gorman-Rupp Company). Players in the market are adopting strategies such as partnerships and acquisitions to enhance their product offerings and gain sustainable competitive advantage.

June 2024 - Ingersoll Rand Inc. successfully finalized its acquisition of ILC Dover (ILC). In addition, the company bolstered its portfolio by acquiring Complete Air and Power Solutions (CAPS), Del PD Pumps & Gear Pvt. Ltd (Del Pumps), and Fruvac Ltd (Fruitland Manufacturing) for a consolidated sum of around USD 150 million.

September 2023 - Busch unveiled its latest innovation, the energy-efficient R5 RA vacuum pump. This pump boasts a sleek, hygienic design, lower heat emissions, and streamlined maintenance. The Ecotorque variable speed drive, an optional feature, delivers an impressive 50% boost in energy efficiency and a 20% uptick in pumping speed. Moreover, this accessory expands the pump's voltage range, enhancing its global usability.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumption and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Industry Value Chain Analysis

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Increasing Demand for PD Pumps Due to Huge Scarcity in the Disposable Water Level and Groundwater Adulteration

- 5.1.2 Increasing Demand From the Oil and Gas Industry

- 5.2 Market Challenges

- 5.2.1 High Cost and Compatibility Issues

6 MARKET SEGMENTATION

- 6.1 By Type of Pump

- 6.1.1 Diaphragm Pump

- 6.1.2 Piston Pump

- 6.1.3 Gear Pump

- 6.1.4 LobePump

- 6.1.5 Progressive Cavity Pump

- 6.1.6 Screw Pump

- 6.1.7 Vane Pump

- 6.1.8 Peristaltic Pump

- 6.1.9 Plunger Pump

- 6.2 By End-user Industry

- 6.2.1 Oil and Gas

- 6.2.2 Chemicals

- 6.2.3 Food and Beverage

- 6.2.4 Water and Wastewater

- 6.2.5 Pharmaceutical

- 6.2.6 Power Generation

- 6.2.7 Other End-user Industries

- 6.3 By Country

- 6.3.1 Saudi Arabia

- 6.3.2 United Arab Emirates

- 6.3.3 Kuwait

- 6.3.4 Africa

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Dover Corporation

- 7.1.2 Ingersoll Rand Inc.

- 7.1.3 Watson-Marlow Fluid Technology Solutions (Spirax Group PLC)

- 7.1.4 Alfa Laval AB

- 7.1.5 Gorman-Rupp Corporation (Gorman-Rupp Company)

- 7.1.6 Busch Vacuum Solutions Inc. (Busch Group)

- 7.1.7 Celeros Flow Technology Inc.

- 7.1.8 Flowserve Corporation

- 7.1.9 Atlas Copco AB

- 7.1.10 Xylem Inc.

8 MARKET OUTLOOK