PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1523334

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1523334

Automotive Aluminium Extrusion - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029)

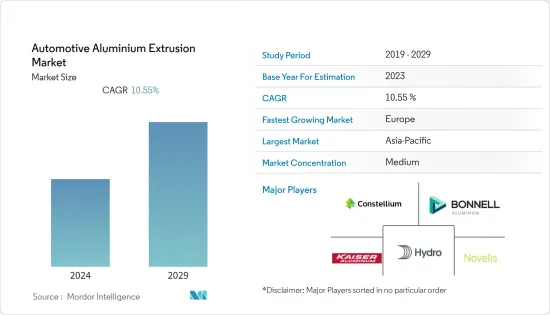

The Automotive Aluminium Extrusion Market size is estimated at USD 32.05 billion in 2024, and is expected to reach USD 64.11 billion by 2029, growing at a CAGR of 10.55% during the forecast period (2024-2029).

The automotive aluminum extrusion market is currently experiencing significant growth. A major force propelling this market is the automotive industry's ongoing shift toward lightweight materials. In response to stringent global emission standards and an increasing focus on fuel efficiency, aluminum extrusions are gaining popularity due to their low weight yet high strength. This trend is particularly crucial in the development of electric vehicles (EVs), where reducing weight is essential for enhancing range and efficiency.

In terms of design, aluminum extrusions offer unparalleled flexibility, allowing for the creation of complex, integrated shapes suitable for various automotive applications. This versatility is advantageous for structural components, chassis, body panels, and crash structures. Additionally, aluminum's excellent thermal conductivity makes it an ideal choice for heat exchangers and EV battery housing applications.

Technological advancements in extrusion technology, including improved alloys and precision manufacturing techniques, have also played a significant role. These advancements have enhanced the quality of aluminum extrusions and made them more cost-effective, broadening their use across the automotive industry.

Economically, the market is influenced by regional trends and developments. Asia-Pacific, known for its booming automotive industry and robust manufacturing capabilities, is a significant player in the aluminum extrusion market. Meanwhile, with their strict emission regulations and high adoption rates of EVs, North America and Europe are driving demand for these materials.

The automotive aluminum extrusion market is poised for continued growth shaped by the industry's move toward lightweight, sustainable, and efficient materials, technological improvements, and the evolving global automotive landscape.

Automotive Aluminium Extrusion Market Trends

Passenger Cars are Fueling the Market's Growth

The dominance of passenger cars in the aluminum extrusion market is primarily driven by the automotive industry's ongoing trend toward lightweight materials. Aluminum extrusions are particularly favored for their exceptional strength-to-weight ratio, which makes them an ideal choice for reducing vehicle weight. This reduction is critical for enhancing fuel efficiency and plays a significant role in lowering emissions, aligning with global environmental standards and consumer preferences for greener vehicles.

The design versatility and performance advantages offered by aluminum extrusions are substantial. They allow for the creation of lightweight and robust complex shapes that meet the stringent aesthetic and functional requirements of modern car designs. The material's inherent resistance to corrosion and overall durability further contribute to the longevity and performance of vehicles.

The escalating production of electric vehicles (EVs) also significantly contributes to the demand for aluminum extrusions in passenger cars. Weight reduction is particularly beneficial in EVs as it directly affects battery range and efficiency, making aluminum an increasingly popular choice for EV structures and battery housings.

Additionally, advancements in extrusion technology have rendered aluminum extrusion a cost-efficient manufacturing process. This aspect is crucial as the automotive industry consistently seeks methods to minimize production costs while maintaining high quality. Aluminum extrusions effectively balance cost and performance, making them highly attractive to vehicle manufacturers.

This increase in global production underscores the growing importance of aluminum extrusions in the automotive industry, consolidating the position of passenger cars as a leading segment in the aluminum extrusion market.

Asia-Pacific Dominates the Market's Growth

Asia-Pacific's dominance in the automotive aluminum extrusion market results from several interconnected factors that reflect its dynamic economic and industrial landscape.

Firstly, the region's rapid industrial growth, especially in powerhouse economies like China, India, and Southeast Asian countries, has significantly propelled the demand for aluminum extrusions. These materials are extensively used across diverse sectors and industries, including automotive, construction, and electronics, which are all flourishing in the region.

In the automotive industry, Asia-Pacific stands out as a major consumer market and a key manufacturing and exporting hub. Countries such as China, Japan, and South Korea have large automotive industries that are increasingly turning to lightweight materials like aluminum extrusions. The need for better fuel efficiency and adherence to strict emission standards largely drives this shift.

The region has also made substantial advancements in manufacturing technologies and capabilities aided by the availability of cheap labor and technological investments. This trend has established Asia-Pacific as a cost-effective production center for aluminum extrusions.

Additionally, the region's significant export potential, catering to markets in Europe and North America, is underpinned by its extensive production capacity and the global demand for aluminum extrusions.

Automotive Aluminium Extrusion Industry Overview

The automotive aluminum extrusion market is moderately consolidated. The market is characterized by the presence of considerably large players that have tie-ups with major automotive manufacturers. The companies are entering strategic partnerships, acquisitions, and product developments to expand their brand portfolios.

Some of the important players in the market include Novelis Inc., Constellium NV, Norsk Hydro ASA, Kaiser Aluminum, and Kobelco Aluminum Products & Extrusions Inc. Key players are investing in expanding their facilities worldwide. For instance,

- In September 2023, Hindalco Industries Ltd announced a technology partnership with Metra SpA, an Italian company renowned for its expertise in crafting structured and high-value aluminum extrusions.

- This collaboration strategically aims to enhance Hindalco's capabilities in producing large-scale aluminum extrusion and advanced fabrication technology. This partnership signifies a significant step for Hindalco to leverage Metra SpA's specialized knowledge to expand its production scope and technological prowess in the aluminum extrusion domain.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Drivers

- 4.1.1 Rising Demand for Electric Vehicles Fueling the Market's Growth

- 4.2 Market Restraints

- 4.2.1 Fluctuating Raw Material Prices Anticipate to Restrain the Market's Growth

- 4.3 Industry Attractiveness - Porter's Five Forces Analysis

- 4.3.1 Bargaining Power of Suppliers

- 4.3.2 Bargaining Power of Consumers

- 4.3.3 Threat of New Entrants

- 4.3.4 Intensity of Competitive Rivalry

- 4.3.5 Threat of Substitute Products

5 MARKET SEGMENTATION

- 5.1 Type

- 5.1.1 Body Structure

- 5.1.2 Interiors

- 5.1.3 Exteriors

- 5.1.4 Other Types

- 5.2 Application

- 5.2.1 Passenger Cars

- 5.2.2 Light Commercial Vehicles

- 5.2.3 Medium and Heavy-duty Commercial Vehicles

- 5.2.4 Buses

- 5.3 Geography

- 5.3.1 North America

- 5.3.1.1 United States

- 5.3.1.2 Canada

- 5.3.1.3 Rest of North America

- 5.3.2 Europe

- 5.3.2.1 Germany

- 5.3.2.2 United Kingdom

- 5.3.2.3 France

- 5.3.2.4 Spain

- 5.3.2.5 Rest of Europe

- 5.3.3 Asia-Pacific

- 5.3.3.1 India

- 5.3.3.2 China

- 5.3.3.3 Japan

- 5.3.3.4 South Korea

- 5.3.3.5 Rest of Asia-Pacific

- 5.3.4 Rest of the World

- 5.3.4.1 South America

- 5.3.4.2 Middle East and Africa

- 5.3.1 North America

6 COMPETITIVE LANDSCAPE**

- 6.1 Vendor Market Share

- 6.2 Company Profiles *

- 6.2.1 Constellium SE

- 6.2.2 Norsk Hydro ASA

- 6.2.3 Novelis Inc.

- 6.2.4 Kobelco Aluminum Products & Extrusions Inc.

- 6.2.5 Bonnell Aluminum Extrusion Company

- 6.2.6 Kaiser Aluminum Corp.

- 6.2.7 Innoval Technology

- 6.2.8 SMS Schimmer

- 6.2.9 Omnimax International

- 6.2.10 Walter Klein GmbH & Co. KG

- 6.2.11 BENTELER International

7 MARKET OPPORTUNITIES AND FUTURE TRENDS