PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1521901

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1521901

Pallet Pooling/Rentals - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029)

The Pallet Pooling/Rentals Market size in terms of shipment volume is expected to grow from 6.15 Billion units in 2024 to 7.89 Billion units by 2029, at a CAGR of 5.11% during the forecast period (2024-2029).

Key Highlights

- Pallet pooling/rentals is a share-and-reuse framework based on circular economy principles. It offers a sustainable and efficient alternative to traditional single-use pallets. Various pallets, such as plastic pallets, wood pallets, and others, are circulated among stakeholders, including producers, distributors, retailers, and transporters, fostering efficiency and sustainability. This method has gained traction as a pivotal pallet management strategy,

- Various key players, such as PECO, PCT, IGPS, and CHEP, are encouraging the reduction of single-use pallets and offering end users the opportunity to switch to multi-use pallets. Manufacturers such as PCT provide online platforms for pallet users to establish personalized pallet pools, fostering sustainability by connecting them directly with suppliers and customers.

- There is a rising focus on lightweight and sustainable materials in the design and manufacture of pallets. Providers in the pallet pooling sector are increasingly turning to materials such as plastic, metal alloys, composite wood, and presswood pallets. These materials provide durability and strength and align with environmental sustainability goals. Additionally, they help cut down on transportation costs and lower carbon emissions.

- Reverse logistics, encompassing product returns, recalls, and recycling, is increasingly pivotal in the pallet pooling market. Providers in this sector now offer reverse logistics solutions to aid companies in streamlining pallet returns, enhancing asset utilization, and curbing waste in their supply chains.

- Additionally, trends such as pallet stockpiling underscore the underconsumption of pallet assets. Smart pallet monitoring technologies facilitate a digital shift in the availability and usage of pallet stocks.

- However, supply chain continuity faces a significant threat due to pallet theft, which is driven by supply shortages and soaring demand. CHEP, one of the key players in the market, estimates that Europe witnesses the theft of millions of pallets annually, either with their cargo or used illicitly. Given the industry's growing dependence on pallet circularity, these losses are becoming potential disruptions to the supply chain.

- However, smart pallet monitoring minimizes losses by offering real-time data insights on shipments and pallets. These insights are channeled to a dashboard, accessible remotely, and equipped with pre-set alerts, geofencing, and tracking features. Thus, remote monitoring technology can track shipments throughout the supply chain, even in high-risk shipping zones and with high-value shipments, ensuring timely delivery and efficient pallet circulation. In case of theft, these smart monitoring systems significantly enhance the chances of recovery.

Pallet Pooling/Rentals Market Trends

Rising Demand for Plastic Pallets in Pooling Systems

- In the dynamic logistics and supply chain management landscape, businesses increasingly use innovative transportation solutions, such as plastic pallet pooling systems. These solutions aim to enhance efficiency, reduce costs, and promote environmental sustainability.

- Plastic pallets are lighter than their traditional counterparts, making them easier to handle and transport. Reduced weight of plastic pallets not only streamlines logistics but also enhances fuel efficiency in transportation, ultimately reducing carbon emissions.

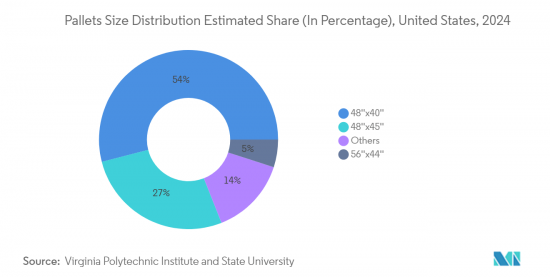

- Plastic pallets are typically manufactured from high-density polyethylene (HDPE) or polypropylene (PP). They are available in different shapes, designs, and sizes in various countries; for instance, plastic pallets with sizes 48''x48'', 48''x45'', and others are popular in the United States.

- Additionally, plastic pallets can be tailored to specific requirements, optimizing warehouse operations. Businesses can maximize space utilization and reduce waste by customizing plastic pallets to accommodate various products.

- Moreover, plastic pallets are gaining popularity in pooling systems among various users due to their beneficial properties, such as being nonabsorbent of moisture, durable, and recyclable. The durability of plastic pallets ensures a longer use period and minimizes the need for frequent replacements. This longevity translates into fewer resources being used over time, contributing to resource conservation and waste reduction.

- Plastic pallets are increasingly favored in pooling systems for various advantages, such as being resistant to moisture and recyclable. Moreover, plastic pallets' durability extends their lifespan and reduces the frequency of replacements. This longevity not only conserves resources but also aids in waste reduction. Businesses can significantly reduce their environmental footprint and support a more sustainable future by opting for plastic pallets in the pooling system, thus increasing the popularity of plastic pallets in the pooling system globally.

- Also, due to their uniformity, plastic pallets enable precise calibration of automated palletizers, conveyor belts, and automated storage and retrieval systems (ASRS). Their nail and splinter-free design minimizes equipment damage, ensuring automated systems run at peak efficiency, reducing downtime, and boosting demand for plastic pallets in the pooling system globally.

North America Dominates the Pallet Pooling/Rentals System

- The increasing emphasis on sustainability in North America drives end users to embrace pallet pooling systems. Pallet pooling, a management strategy, fosters pallet reuse and cost savings and is an underappreciated environmental best practice.

- Additionally, pallet pooling offers several benefits to users, such as reducing the need to manufacture new pallets and resulting in lower cost per trip compared to single-use pallets, which is gaining attention among the end users in this region.

- In North America, two primary pallet pooling models are prevalent, especially in industries like the fast-moving consumer goods (FMCG) sector. These models include third-party rental and the Grocery Manufacturers Association (GMA) common pool.

- Pallets with dimensions 48"x40" are commonly referred to as GMA pallets and are widely used in North America. Notably, Pallet rental is dominated by a handful of large players in the United States, which need extensive pallet inventories and a robust retrieval network.

- Small rental providers in North America also provide tailored pallet solutions to less complex supply chains. Users benefit from renting premium-quality pallets at a lower cost than purchasing a new pallet, thus supporting the growth of this region's pallet pooling/rental market.

Pallet Pooling/Rentals Industry Overview

The pallets pooling/rental market is fragmented, with various global and local players operating. The market players have adopted key developmental strategies, such as new technological advancements, to fuel the pallets pooling/rental market growth in terms of value sales. The companies also continuously focus on R&D to keep a strong foothold in the market and boost the demand for pallets on a rental basis. Key pallet pooling/rental market players include iGPS Logistics, LLC, Orbis Corporation, CHEP (Brambles Limited), PECO Pallet Inc., and IFCO Management GmbH.

In January 2024, IFCO, the world's leading provider of Reusable Packaging Containers (RPCs), launched 'Dora,' a reusable plastic pallet in Europe. It will be available through IFCO's circular pooling system. Dora effortlessly integrates into current fresh grocery supply chains. This integration not only enhances logistics efficiency but also bolsters sustainability efforts for both suppliers and retailers. The IFCO Plastic Pallet enhances efficiency, reduces transportation costs, and improves safety in critical areas of the transportation sector.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Value Chain Analysis

- 4.3 Industry Attractiveness - Porter's Five Forces Analysis

- 4.3.1 Bargaining Power of Suppliers

- 4.3.2 Bargaining Power of Buyers

- 4.3.3 Threat of New Entrants

- 4.3.4 Threat of Substitute Products

- 4.3.5 Intensity of Competitive Rivalry

- 4.4 Industry Regulations, Policies, and Standards for Pallet Management Globally

- 4.5 Emerging Trends in Pallet Industry & Development of New Pallet Formats

- 4.6 Pallet Volume Shipment Analysis: Overall Pallets Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Growing Innovation in Custom Pallet Design

- 5.1.2 Rising Demand for Plastic Pallets in Pooling System

- 5.2 Market Restraint

- 5.2.1 Increase in Pallet Theft in the Supply Chain

6 MARKET SEGMENTATION

- 6.1 By Material Type

- 6.1.1 Plastic

- 6.1.2 Wood

- 6.1.3 Cardboard

- 6.1.4 Metals

- 6.2 By End-user Industries

- 6.2.1 Transportation & Warehousing

- 6.2.2 Food & Beverages

- 6.2.3 Pharmaceuticals

- 6.2.4 Retail

- 6.2.5 Manufacturing

- 6.2.6 Other End-user Industries

- 6.3 Geography***

- 6.3.1 North America

- 6.3.1.1 United States

- 6.3.1.2 Canada

- 6.3.2 Europe

- 6.3.2.1 France

- 6.3.2.2 Germany

- 6.3.2.3 Italy

- 6.3.2.4 Spain

- 6.3.2.5 United Kingdom

- 6.3.3 Asia

- 6.3.3.1 China

- 6.3.3.2 India

- 6.3.3.3 Japan

- 6.3.3.4 Australia & New Zealand

- 6.3.4 Latin America

- 6.3.4.1 Brazil

- 6.3.4.2 Mexico

- 6.3.4.3 Argentina

- 6.3.5 Middle East and Africa

- 6.3.5.1 United Arab Emirates

- 6.3.5.2 Saudi Arabia

- 6.3.5.3 Egypt

- 6.3.5.4 South Africa

- 6.3.1 North America

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles*

- 7.1.1 CHEP (Brambles Limited)

- 7.1.2 PECO Pallet Inc.

- 7.1.3 iGPS Logistics LLC

- 7.1.4 Orbis Corporation

- 7.1.5 EXZOD India Private Limited

- 7.1.6 IFCO Management GmbH

- 7.1.7 LEAP India Private Limited

- 7.1.8 Schoeller Allibert

- 7.1.9 CABKA Group GMBH

- 7.1.10 NEFAB Group

- 7.1.11 La Palette Rouge

8 INVESTMENT ANALYSIS

9 FUTURE OF THE MARKET