PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1519945

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1519945

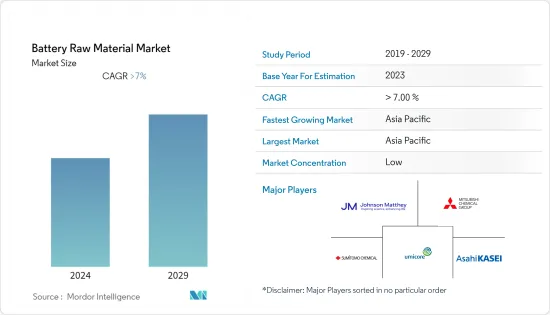

Battery Raw Material - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029)

The Battery Raw Material Market size is estimated at USD 58.70 billion in 2024, and is expected to reach USD 97.23 billion by 2029, growing at a CAGR of 10.62% during the forecast period (2024-2029).

The COVID-19 pandemic disrupted the battery materials market. Lockdown measures, factory closures, and restrictions on movement led to disruptions in mining operations, ore processing facilities, and logistics networks, impacting the supply of raw materials. The resumption of economic activities across industries, including automotive, electronics, and energy, contributed to the recovery of the battery raw materials market.

Key Highlights

- The market for battery raw materials is proliferating due to the increasing use of these products in the automotive and consumer electronics sectors.

- However, the growth of the battery raw materials market is expected to be hampered by strict safety regulations for batteries through storage and transport.

- The rising research and development activities in vanadium flow technology and increasing demand for portable electronics and consumer devices are expected to provide opportunities for the battery raw material market in the coming years.

- The growing consumption of automotive and consumer electronics batteries in countries such as China and India is driving Asia-Pacific to dominate the global market.

Battery Raw Material Market Trends

Automotive Segment to Dominate the Market

- With the rapid rise in the adoption of electric vehicles, the car industry is undergoing a significant change. Various critical raw materials are required for the Lithium-ion battery, which is a crucial energy storage. As EV sales continue to surge globally, the demand for these battery raw materials has skyrocketed, driving growth in the automotive segment of the battery raw materials market.

- According to the estimate released by the International Organization of Motor Vehicle Manufacturers (OICA), around 81.63 million vehicles were sold around the world in 2022.

- Furthermore, according to the Federal Motor Transport Authority, Flensburg, the registration of the total number of battery electric cars in Germany increased from 136,617 units in 2020 to 1,013,009 units in 2023.

- In the consumer electronics and automotive sectors, Asia-Pacific countries such as China, Japan, South Korea, and India are experiencing strong growth in the use of battery raw materials, which is expected to drive the market over the forecast period.

- The expansion of EV charging infrastructure worldwide has bolstered consumer confidence in EVs and fueled the adoption of electric vehicles. Governments, utilities, and private companies are investing heavily in the deployment of charging stations, fast-charging networks, and smart grid technologies. Thus, this supports the growing fleet of EVs. This infrastructure development has created a robust market for battery raw materials to meet the increasing demand for lithium-ion batteries in automotive applications.

- According to the data published by the Federal Network Agency, in Germany, there were 87,155 public sites with average speed recharging for EVs available in October 2023 and 21,111 public quick charge stations.

- The increase in the adoption of electric vehicles aligns with the clean energy policy. The Chinese government intends to relax restrictions on the import of vehicles by automobile manufacturers into China in order to narrow the supply gap for demand.

- The market for battery materials is expected to be driven by all of the above factors during the forecast period.

Asia-Pacific to Dominate the Market

- Asia-Pacific is an important manufacturing hub for a wide range of sectors, from automotive to electronics and renewables. The region hosts a large number of battery manufacturers, cell producers, and suppliers of battery raw materials. This concentration of manufacturing facilities drives demand for battery raw materials in Asia-Pacific.

- The Asia-Pacific market for electric vehicles is growing at a rapid rate in countries such as China, Japan, and South Korea. These countries are the biggest producers and consumers of electric vehicles in the world. The production of lithium-ion batteries for EVs requires significant quantities of battery raw materials such as lithium, cobalt, nickel, and graphite, contributing to the dominance of Asia-Pacific in the battery raw materials market.

- According to the data published by the China Association of Automobile Manufacturers (CAAM), in China, approximately 5.4 million battery electric vehicles were sold in 2022, an increase of 83,5 % compared to 2021. In the same year, there was an increase of 151.91% in sales of plugin hybrids to over 1.5 million vehicles in China from a year earlier.

- According to the data published by the Automobile Inspection & Registration Information Association, Japan (AIRIA), in 2023, the number of electric passenger cars in use in Japan increased to about 162.39 thousand vehicles, which was an increase from 10 years ago.

- In India, according to Vahan's data, EV sales in March 2023 increased by 82 % Y-o-Y, with 1,39,789 units sold compared to 77,128 EVs sold in March 2022. In total, sales increased by a staggering 157% in the period, from 4,58,746 to 11,80,597 during fiscal year 2022.

- Therefore, the demand for battery raw materials in the region during the forecast period is expected to be driven by all these market developments.

Battery Raw Material Industry Overview

The battery raw material market is fragmented, with the presence of a few large-sized players and a large number of small players operating. The major players (not in any particular order) include Umicore, Asahi Kasei Corporation, Johnson Matthey, Sumitomo Chemical Co. Ltd, and Mitsubishi Chemical Corporation.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Growing Demand from Consumer Electronics

- 4.1.2 Rising Application in Automotive Industry

- 4.2 Restraints

- 4.2.1 Stringent Safety Regulations for Batteries through Storage and Transportation

- 4.2.2 Other Restraints

- 4.3 Industry Value Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Buyers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION (Market Size in Value)

- 5.1 By Battery Type

- 5.1.1 Lead-acid

- 5.1.2 Lithium-ion

- 5.1.3 Other Battery Types (Nickel-metal Hydride (NiMH), and Solid-state Batteries)

- 5.2 By Material

- 5.2.1 Cathode

- 5.2.2 Anode

- 5.2.3 Electrolyte

- 5.2.4 Separator

- 5.3 By Application

- 5.3.1 Consumer Electronics

- 5.3.2 Automotive

- 5.3.3 Industrial

- 5.3.4 Telecommunication

- 5.3.5 Other Applications (Renewable Energy Storage)

- 5.4 By Geography

- 5.4.1 Asia-Pacific

- 5.4.1.1 China

- 5.4.1.2 India

- 5.4.1.3 Japan

- 5.4.1.4 South Korea

- 5.4.1.5 Thailand

- 5.4.1.6 Malaysia

- 5.4.1.7 Indonesia

- 5.4.1.8 Vietnam

- 5.4.1.9 Rest of Asia-Pacific

- 5.4.2 North America

- 5.4.2.1 United States

- 5.4.2.2 Canada

- 5.4.2.3 Mexico

- 5.4.3 Europe

- 5.4.3.1 Germany

- 5.4.3.2 United Kingdom

- 5.4.3.3 France

- 5.4.3.4 Italy

- 5.4.3.5 Spain

- 5.4.3.6 Turkey

- 5.4.3.7 Russia

- 5.4.3.8 NORDIC

- 5.4.3.9 Rest of Europe

- 5.4.4 Rest of the World

- 5.4.4.1 South America

- 5.4.4.2 Middle East and Africa

- 5.4.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Share (%) **/ Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 Asahi Kasei Corporation

- 6.4.2 BASF SE

- 6.4.3 Celgard LLC

- 6.4.4 ENTEK

- 6.4.5 ITOCHU Corporation

- 6.4.6 Johnson Matthey

- 6.4.7 Mitsubishi Chemical Corporation.

- 6.4.8 NICHIA CORPORATION

- 6.4.9 Sumitomo Chemical Co. Ltd

- 6.4.10 Targray Technology International Inc.

- 6.4.11 Umicore

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Research and Development in Vanadium Flow Technology in Batteries

- 7.2 Increasing Demand for Portable Electronics and Consumer Devices