PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1640586

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1640586

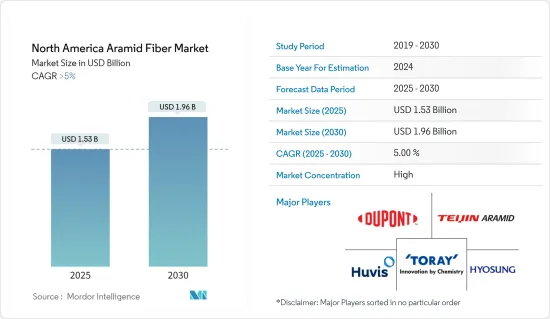

North America Aramid Fiber - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

The North America Aramid Fiber Market size is estimated at USD 1.53 billion in 2025, and is expected to reach USD 1.96 billion by 2030, at a CAGR of greater than 5% during the forecast period (2025-2030).

The North America Aramid Fibers Market had been negatively affected by the COVID-19 pandemic. The United States was worst hit by the COVID pandemic in the region. The COVID pandemic resulted in lockdowns in the United States, Canada, and Mexico, affecting the automotive, electrical and electronics, aerospace, and defense end-user industries, thereby affecting the market for aramid fibers. However, the market recovered well after the restrictions were lifted. The market recovered significantly, owing to the rise in consumption of aramid fibers in automotive, electrical, and electronics end-user industries.

Key Highlights

- Over the short term, the increasing demand for lightweight materials in aerospace and defense industries, the increase in demand for lightweight materials in the automotive industry, and the rising usage of aramid fibers as a potential substitute for steel materials are excepted to drive the market.

- The non-biodegradable nature of aramid fibers and the increasing prices of raw materials are hindering market growth.

- The advancements in aramid materials manufacturing technology are expected to create opportunities for the market during the forecast period.

- The United States is expected to dominate the market due to the rising demand for aramid fibers from automotive, aerospace and defense, electrical, and electronics end-user industries. It is also expected to register the highest CAGR during the forecast period.

North America Aramid Fiber Market Trends

Aerospace and Defense End-User Industry to Dominated the Market

- Aramids are used for components and structural applications in all aircraft and spacecraft, ranging from hot air balloons and gliders to fighter planes, passenger airliners, and space shuttles. The aramid fibers are generally used in wing assemblies, helicopter rotor blades, seat propellers, and enclosures for instruments and internal parts.

- Every year, the aerospace industry uses a higher proportion of aramid fibers in constructing each new generation of aircraft due to the provision of an all-weather operation of commercial aircraft and enhanced vision systems. Moreover, characteristics such as temperature stability and durability will further fuel the growth of the aerospace composites market over the coming years.

- The United States is one of the significant markets for OEMs of airplanes in the North American region. Airbus and Boeing are the largest manufacturers of airplanes in the country. For instance, Airbus delivered 735 commercial aircraft in 2023, an 11% increase on 2022. 2,319 gross orders (2,094 net), including 1,835 A320 Family and 300 A350 Family aircraft. Similarly, Boeing Aeroplane OEM company received orders for 57 Boeing Max 8 jets, with delivery expected through 2025.

- According to data from the Bureau of Transportation Statistics, in 2022, airlines in the United States carried 853 million passengers at a growth rate of 30% compared to 674 million passengers in 2021. Thus, several airline companies are expanding their fleet and procuring aircraft with advanced capabilities to cater to the increasing air passenger demand.

- Mexico is one of the prominent players in the North American Aerospace Industry. Aerospace manufacturing in Mexico now produces everything from engines, cargo doors, fuselages, engine parts, landing gear assemblies, connection systems, and many other components essential for an aircraft to function.

- The number of passengers traveling by airplane is increasing in Mexico. Thus, the demand for new civil aircraft is increasing in the country. According to Mexican Aerospace Industry Federation, A.C. (FEMIA), Mexico's aerospace sector grew from 100 manufacturing firms and organizations in 2004 to 368 by mid-2022. Today these firms primarily include manufacturers and maintenance-repair-overhaul facilities (MROs) for civil aircraft.

- Thus, the aerospace and defense industry growth is expected to drive the region's aramid fibers market.

United States to Dominate the Market

- The United States dominated the aramid fiber market in the North American region. The United States is one of the fastest emerging economies and has become one of the biggest production houses in the world today. The country's manufacturing sector is one of the significant contributors to the country's economy.

- The United States is one of the region's significant markets for Aramid Fibers. These are sued in various end-user industries such as aerospace and defense: Automotive, electric and electronics, and sporting goods. In the United States, the automotive and aerospace sectors registered significant market growth, thereby driving the market for aramid fibers in the country.

- The United States electronics market is the largest in the world, acting as one of the leading potential zones for the market studied. There is a significant increase in the number of manufacturing plants and development centers in the United States, primarily due to the focus on developing high-end products.

- In the United States, the rapid pace of innovation in terms of the advancement of technologies and R&D activities in the electronics industry is driving the demand for newer and faster electronic products. According to the Consumer Technology Association, the retail revenue from consumer electronics/technology sales in the United States was estimated at USD 505 billion in 2022, compared to USD 461 billion in 2021. the growth in sales is an estimation of enhanced consumption of aramid fibers from the electronics segment of the country.

- The automobile industry in the United States is the second-largest after China, contributing significantly to the regional and global automobile markets. The country houses major automakers producing and exporting vehicles to other economies in the Americas, Europe, and the Asia Pacific.

- According to OICA (The Organisation Internationale des Constructeurs d'Automobiles), vehicle production in the country reached a total of 10.06 million units in 2022, compared to 9006 million units manufactured in 2021, at a growth rate of 10%.

- Overall, the growth of industries such as automotive and electronics will likely drive the market for aramid fibers in the country during the forecast period.

North America Aramid Fiber Industry Overview

The North America aramid fiber market is consolidated in nature. Some of the key players in the market (not in any particular order) include Dupont, Huvis Corp, HYOSUNG, Teijin Aramid, and TORAY INDUSTRIES, INC.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Increasing Demand for Light Weight Materials in Aerospace and Defense Industries

- 4.1.2 The Increase in Demand for Light Weight Materials in Automotive Industry

- 4.1.3 The Rising Usage of Aramid Fibers as a Potential Substitute for Steel Materials

- 4.2 Restraints

- 4.2.1 Non-Biodegradable Nature of Aramid Fibers

- 4.2.2 The Increasing Prices of Rawmaterials

- 4.3 Industry Value-Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Buyers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION (Market Size in Value)

- 5.1 Product Type

- 5.1.1 Para-aramid

- 5.1.2 Meta-aramid

- 5.2 End-user Industry

- 5.2.1 Aerospace and Defense

- 5.2.2 Automotive

- 5.2.3 Electrical and Electronics

- 5.2.4 Sporting Goods

- 5.2.5 Other End-user Industries (Oil & Gas, Telecommunication, etc.)

- 5.3 By Geography

- 5.3.1 North America

- 5.3.1.1 United States

- 5.3.1.2 Canada

- 5.3.1.3 Mexico

- 5.3.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Share (%)**/Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 Aramid Hpm, LLC.

- 6.4.2 Bally Ribbon Mills

- 6.4.3 Dupont

- 6.4.4 Huvis Corp

- 6.4.5 HYOSUNG

- 6.4.6 KERMEL

- 6.4.7 Shenma Industrial Co. Ltd.

- 6.4.8 Teijin Aramid

- 6.4.9 TORAY INDUSTRIES, INC.

- 6.4.10 Yantai Tayho Advanced Materials Co.,Ltd.

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Advancements in Aramid Materials Manufacturing Technology

- 7.2 Other Opportunities