PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1644458

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1644458

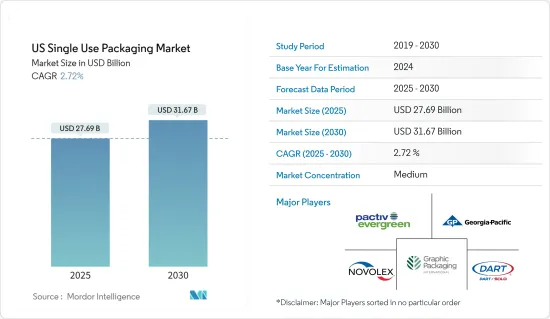

US Single Use Packaging - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

The US Single Use Packaging Market size is estimated at USD 27.69 billion in 2025, and is expected to reach USD 31.67 billion by 2030, at a CAGR of 2.72% during the forecast period (2025-2030).

The demand for single-use packaging in the country is anticipated to increase due to its high convenience and printability. Single-use plastic packaging is required by several businesses to avoid cross-contamination and disease. It will accelerate the expansion of the market for single-use packaging.

Key Highlights

- The increasing need for small and more convenient packaging and a strong visual impact is expected to contribute to the growth of single-use packaging over the forecast period. Single-use packaging is for products used only once before they are thrown away or recycled. These items are plastic bags, straws, coffee stirrers, soda and water bottles, and most food packaging.

- The United States' flexible plastic packaging industry is witnessing healthy growth as it implemented innovative solutions for the several packaging challenges it faced. According to the Flexible Packaging Association (FPA), brand owners are adopting pouches, films, and bags as a go-to packaging solution, partly due to rising acceptance by American consumers.

- The pharmaceutical industry is driving the expansion of single-use plastic packaging in the nation's market. Medical equipment, supplies, syringes, and medications are frequently packaged in single-use plastic since it decreases the possibility of contamination, protecting the end-users interests. Further, the market for single-use plastic beverage containers is predicted to expand due to the rising production of various package sizes to meet the growing demand for bottled water, soft drinks, alcoholic beverages, ready-to-drink beverages, and milk.

- However, growing issues with single-use plastic packaging include waste and disposal management. Environmental risks and a rise in plastic waste result from improper disposal. It will probably hamper the market for single-use plastic packaging in the country.

- The United States has witnessed a significant acceleration in e-commerce, driven by lockdowns imposed due to the outbreak of COVID-19. However, the pandemic made a dent in retail sales at the start of 2020. Such factors negatively impacted the usage of flexible plastic packaging in the US retail landscape in the respective months. However, the retail sector in the United States witnessed a significant surge in late 2020, which bounced back the usage of single-use flexible plastic packaging in the region. Further, the Russia-Ukraine war has an impact on the overall packaging ecosystem.

US Single Use Packaging Market Trends

Flexible Single-use Plastic Packaging Products Offering Increased Convenience and Utility

- According to Biologicaldiversity.org, American citizens use 100 billion plastic bags annually, which require 12 million barrels (1907.85 million liters) of oil to manufacture. Americans use an average of 365 plastic bags per person per year. People in Denmark use an average of four plastic bags per year.

- Moreover, the spread of coronavirus has temporarily increased the adoption of single-use plastic due to its barrier properties. The primary users are restaurants, grocery stores, and e-commerce vendors. Grocery stores have sharply increased plastic bag usage. Households are generating up to 50% more waste by volume than pre-pandemic, indicating increased demand. Still, as soon as the state achieves near-normal scenarios, the pre-covid established regulations to ban single-use plastics are expected to subside the circulation of these packaging materials.

- In comparing single-use packaging to reusable tableware in quick-service restaurants (QSR), single-use systems have their advantages, particularly in carbon emissions and freshwater consumption. These are due to the energy and water needed to wash, sanitize, and dry multi-use tableware. In the baseline scenario, the polypropylene-based multi-use system generated over 2.5 times more CO2 emissions and used 3.6 times the amount of freshwater than the paper-based single-use system.

- As a result, the market for single-use plastics might sustain if the vendors in the market introduce packaging with higher recycling rates or include materials that help in decomposition. The above concerns have led to the entry of new players in the market that are introducing bio-based single-use plastic products.

- According to the ITC, in 2021, the value of imports of plastic waste and scrap amounted to around USD 368.729 million, a 58.28% growth in imports from the previous year, indicating the demand for an increase in the transformation of plastic debris to single-use plastic.

Healthcare and Pharmaceutical Segment to Witness Significant Growth Rates

- The growing usage of single-use packaging, plastic-based packaging materials, and the increasing demand for medical products and packaging amid the pandemic has significantly spiked plastic waste generation worldwide. One primary need was disposing plastic-based parts of the coronavirus testing kits employing RT-PCR for hygienic concerns.

- Although single-use plastics are increasingly banned worldwide, concerns of cross-contamination by reusing plastic bags and containers have forced countries like the United States to temporarily revoke or defer bans on single-use plastics during the COVID-19 pandemic. Further, a statewide ban on plastic bags in New York initiated in March 2020 was put on hold in May 2020 owing to the pandemic. California and Oregon also suspended their bans on plastic bags, while Connecticut, Delaware, Hawaii, New Jersey, New Mexico, Oregon, Washington, etc., postponed similar prohibitions.

- The majority of PPEs are made up of polymers like polyurethane (PU), polypropylene (PP), polycarbonate (PC), low-density polyethylene (LDPE), and polyvinyl chloride (PVC). PS and LDPE are rarely recycled plastics; PET and HDPE are widely recycled, while PVC and PP are often not recycled.

- An effective material is needed to meet the vast healthcare needs best while considering its influence on the environment. However, maintaining the degree of sterility and sanitation necessary for protecting patients and employees while identifying appropriate and reasonably priced alternatives to plastic is difficult. The growing population puts extra strain on the ability to provide medical supplies on a large scale and on time. Thus, it is anticipated that single-use plastics will continue contributing significant shares in the healthcare sector.

- According to the CMS, national health expenditure per capita is expected to exceed USD 17,000 in 2028. The increase in the health expenditure values may drive the market by necessitating the adoption of sterilizing products increasing the number of single-use packaging companies to witness significant growth in the pharmaceutical sector.

US Single Use Packaging Industry Overview

The single-use packaging market in the United States is moderately consolidated, with new firms entering the market as well as the entry of a few dominant firms, including Dart Container Corporation, Georgia-Pacific LLC, Graphic Packaging International Inc, Novolex, and others. The firms keep innovating and entering strategic partnerships to retain their market share.

In July 2022, Georgia-Pacific's Broadway mill received an investment of USD 500 million for expansion. The expenditures will significantly improve the company's retail consumer tissue and towel business. Through-air-dried (TAD) technology is being used to construct a new paper mill and add related infrastructure and conversion tools. Georgia-Pacific's premium brands will be able to grow, and their premium private label products, as well as those of present and future clients, will be supported by the changes. 2024 is the projected completion date.

In April 2022, Georgia-Pacific constructed new facilities in McDonough, Georgia, and Jonestown, Pennsylvania, where they will manufacture an original, recyclable paper-padded envelope. Georgia-Pacific has more than tripled its capacity to help satisfy the rising demand for more environmentally friendly e-commerce packaging solutions when paired with the newly increased manufacturing capacity of a third production line at the company's factory in the Phoenix region.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Supply Chain Analysis

- 4.3 Industry Attractiveness - Porter Five Forces

- 4.3.1 Bargaining Power of Suppliers

- 4.3.2 Bargaining Power of Consumers

- 4.3.3 Threat of New Entrants

- 4.3.4 Threat of Substitute Products

- 4.3.5 Intensity of Competitive Rivalry

- 4.4 Key Standards and Regulations

- 4.5 Assessment of Impact of COVID-19 on the Market

- 4.6 Overview of the Global Single-use Packaging Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Ongoing Trend Toward Lightweight and Use of Sustainable Solutions (such as Paper-based Cups)

- 5.1.2 Flexible Single-use Packaging Products Offering Increased Convenience and Utility

- 5.2 Market Challenges

- 5.2.1 Stringent Regulations as Major Impediment to the Growth of Single-use Plastic Packaging Products

- 5.2.2 Rising Environmental Concerns due to Single-use Plastic

6 Market Segmentation

- 6.1 By Material

- 6.1.1 Paper and Paperboard

- 6.1.2 Plastics

- 6.1.3 Aluminium

- 6.1.4 Other Materials

- 6.2 By End-user Industry

- 6.2.1 Food

- 6.2.2 Beverage

- 6.2.3 Healthcare and Pharmaceutical

- 6.2.4 Personal Care

- 6.2.5 Other End-user Industries

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Dart Container Corporation

- 7.1.2 Georgia-Pacific LLC

- 7.1.3 Graphic Packaging International Inc.

- 7.1.4 Novolex

- 7.1.5 Pactiv LLC

- 7.1.6 Snapsil Corporation

- 7.1.7 Berry Global Inc.

- 7.1.8 Amcor Plc

- 7.1.9 PPC Flexible Packaging LLC

- 7.1.10 Fuling Plastic USA, Inc.

8 INVESTMENT ANALYSIS

9 FUTURE OF THE MARKET