PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1643054

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1643054

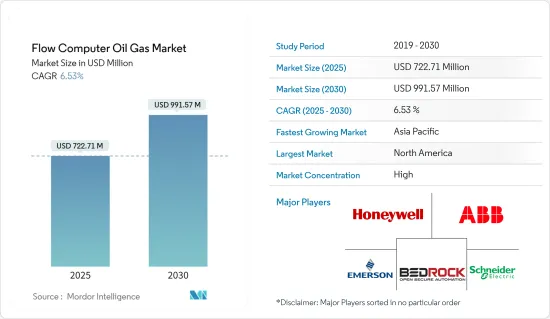

Flow Computer Oil Gas - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

The Flow Computer Oil Gas Market size is estimated at USD 722.71 million in 2025, and is expected to reach USD 991.57 million by 2030, at a CAGR of 6.53% during the forecast period (2025-2030).

The overall function of a flow computer is to calculate and record the flow rate using industry-standard algorithms as natural gas and several hydrocarbons pass through a segmented section of the pipeline. These meters could be but are not limited to orifice meters, ultrasonic meters, linear meters, or Coriolis meters. A typical orifice measurement application requires a differential pressure transmitter, static pressure transducer, and temperature probe.

Key Highlights

- Traditional oil and gas production site designs had one or two wells per pad. In contrast, modern production well pad designs integrate numerous wells, each of which may produce oil, natural gas, and water. Whereas wellhead and facility controls were once performed in separate locations, many more sites perform everything at the same location: the well pad. The economics of the modern oil and gas field requires concentrating measurement and control in a single location.

- The concentration at the wellhead has increased the demand for flow computers, which are supported by sophisticated control algorithms and the ability to provide real-time and historical data to multiple users. As more and more users discover the competitive advantage and productivity improvements they can gain from better data analysis and the requirements to collect, store, process, and transmit data, increasing the demand for high-tech flow computers increases.

- The development of a rugged, single platform equipped with consolidated measurement and controls, edge computing, advanced connectivity, and intrinsic cybersecurity is being sought after by many players in the oil and gas industry. This factor has led to expanding flow computer processing capabilities.

- The most critical risks that a company will face if somebody gets unauthorized access to oil and gas companies' infrastructure are planted sabotage/shutdown, equipment damage, production disruption, utility interruption, product quality, undetected spills, compliance violation, illegal pipeline tapping, safety violation, etc. Specific tactics threaten hackers to try and compromise communications or find a way to maintain a presence in corporate networks for espionage purposes, such as DNS hijacking, attacking webmail and corporate VPN servers, or even scraping publicly available information for data.

- Due to the COVID-19 pandemic, the oil and gas industry witnessed a slowdown in supply growth in the United States and other non-OPEC countries. The global oil demand is expected to contract in 2020, according to a study by the International Energy Agency (IEA). IEA had predicted that the daily need for crude oil was likely to decrease in 2020, from 100.1 million barrels in 2019 to 91.7 million barrels in 2020, due to the economic and mobility impacts of the COVID-19 pandemic which included widespread shutdowns across the world.

Flow Computer Oil Gas Market Trends

Evolving Data Computational Capacity of Flow Computers

- The development of single, rugged platform equipped with consolidated measurement and controls, edge computing, advanced connectivity and intrinsic cyber security by many players for the oil and gas industry has led to the expansion of flow computer processing capabilities.

- Many players like Quorum are already offering integrated solutions for core processing demands across the upstream, midstream and downstream segments of the value chain. Quorum offers its software platform to more than 75% of the top oil and gas producers in the United States.

- Further product improvements in new and traditional technology flowmeters are also contributing to the data capturing ability of such systems. Vortex and turbine suppliers have now started offering flowmeters with two sensors and simultaneously calibrated dual flowmeter. FCI expanded its Adaptive Sensor Technology (AST) to offer ST80 Series Thermal Mass Flow Meter that has enhanced the rangeability, accuracy, extended service life, and reliability for process industry air/gas flow measurement.

- The introduction of these sensors have led to the possibility to create new internal and external applications for flow computeres. For instance, predictive maintenance along with virtual- and augmented-reality capabilities has the potential to enable remote maintenance and technical support thereby reducing flow measurement costs in day to day operations.

- The launch of these sensors has led to the possibility of creating new external and internal applications for flow computers. For instance, predictive maintenance and virtual- and augmented-reality capabilities can enable remote maintenance and technical support, thereby, reducing flow measurement costs in day-to-day operations.

North America to Hold the Largest Market Share

- North America is one of the significant producers of oil and gas across the globe. According to U.S. Energy Information Administration (EIA), in 2020, the United States produced 18.40 million barrels per day (MMb/d) of petroleum and consumed about 18.12 MMb/d. In addition, the country exported 8.51 MMb/d and imported about 7.86 MMb/d of petroleum.

- The government's support is also triggering the growth in the flow measurement devices in the oil and gas industry, which plays a significant role in driving the market for flow computers. For instance, the Bureau of Safety and Environment Enforcement (BSEE) direct final rule came into effect at the end of February 2021.

- Also, according to the United States Department of Transportation, there are more than 2.6 million miles of pipeline that delivers million cubic feet of natural gas and hundreds of billions of tons of petroleum every year.

- Such a vast network of pipelines requires gas metering stations raising the demand for flow metering solutions such as ultrasonic, orifice, and other flow meters.

- The new flow computers launched in the region are conducive to the typical SCADA processes. For instance, the FB1000 and FB2000 flow computers for oil and gas offered by Emerson Electric can be integrated with SCADA and other field devices to accelerate deployment and minimize the time in the field.

Flow Computer Oil Gas Industry Overview

The competitive landscape for the Flow Computer in the Oil and Gas Market is moderately consolidated, with few players like ABB Ltd, Honeywell International Inc., Schneider Electric SE dominating the market. Some of the recent developments of the market are as follows:-

- Feb 2020 - Bedrock Automation has introduced full integration of its flow computer functionality into the existing OSA platform. The new OSA + Flow family integrates industry-leading Flow-Cal measurement applications with the high performance, security, and simplicity of the Bedrock Automation platform.

- Feb 2021 - Quorum announced the merger with Aucerna, a provider of integrated planning, execution, and reserves software for the energy industry, and acquisition of TietoEVRY's entire oil and gas software business As per Quorum, this deal will position Quorum as a global leader for energy software across the upstream, midstream, and downstream sectors of the energy value chain.

- March 2021 - The company announced that Utah Gas Corp. achieved its project milestone with the implementation of FLOWCAL gas measurement software. After the implementation, measurement processes were on time and within budget, and the successfully completed its first monthly close cycle.company

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Value Chain Analysis

- 4.3 Assessment of Impact of COVID-19 on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Growing Need for Reliable Flow and High-tech Computing Systems

- 5.1.2 Continually Evolving Data Computational Capacity of Flow Computers

- 5.2 Market Restraints

- 5.2.1 Cyber-Security Threats Deterring Deployment of Advanced Flow Computer Systems

- 5.2.2 Dynamic Changes in Oil & Gas Prices leading to Reduced Investment in Infrastructure

6 MARKET SEGMENTATION

- 6.1 By Offering

- 6.1.1 Hardware

- 6.1.2 Software

- 6.2 By Geography

- 6.2.1 North America

- 6.2.2 Europe

- 6.2.3 Asia Pacific

- 6.2.4 Latin America

- 6.2.5 Middle East and Africa

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Schneider Electric SE

- 7.1.2 ABB Ltd.

- 7.1.3 Honeywell International Inc.

- 7.1.4 Emerson Electric Company

- 7.1.5 Bedrock Automation Platforms, Inc. (Maxim Integrated Products, Inc.)

- 7.1.6 Yokogawa Electric Corporation

- 7.1.7 Quorum Business Solutions, Inc.

- 7.1.8 OMNI Flow Computers, Inc.

- 7.1.9 Dynamic Flow Computers, Inc.

- 7.1.10 Flowmetrics Inc.

8 INVESTMENT ANALYSIS

9 FUTURE OF THE MARKET