PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1852121

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1852121

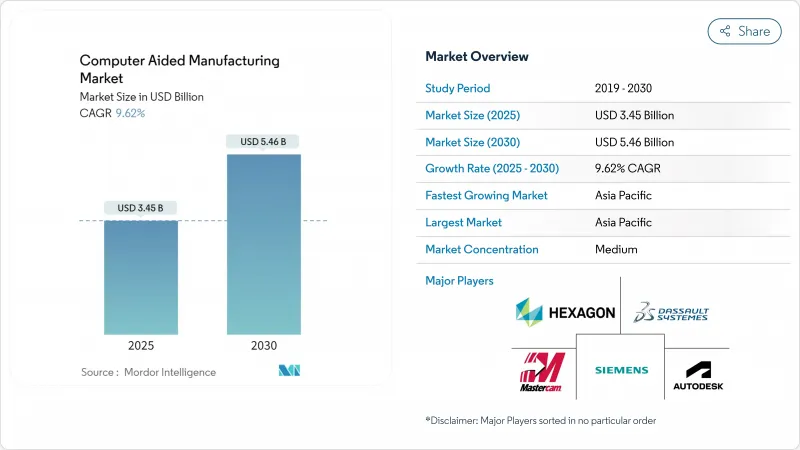

Computer Aided Manufacturing - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

The Computer Aided Manufacturing market size reached USD 3.45 billion in 2025 and is forecast to expand to USD 5.46 billion by 2030, registering a 9.62% CAGR.

Growth stems from the shift to hybrid subtractive-plus-additive production cells, the fusion of artificial intelligence with tool-path generation, and government re-shoring incentives that favor domestic semiconductor packaging and electric-vehicle components. Vendors able to blend cloud-native collaboration with on-premises security benefit from aerospace programs that span multiple continents while respecting defense-grade intellectual-property protocols. Platform consolidation is intensifying as Siemens, Autodesk, and Dassault Systemes embed real-time machine analytics inside their design-to-manufacturing suites, giving users predictive maintenance insight that trumps pure programming speed.

Global Computer Aided Manufacturing Market Trends and Insights

Rise in Hybrid Machining Centers Transforms Production Economics

Hybrid systems integrate laser or directed-energy deposition with high-speed finishing inside one enclosure, eliminating secondary setups and cutting raw-material waste by up to 40%. Siemens NX now automates bead-on-wall deposition and finishing toolpaths so manufacturers deposit material only where needed before achieving aerospace-grade surface finish, reducing overall cycle time for complex titanium parts by 25-30%. Real-world rollouts still hinge on operators trained to synchronize additive and subtractive motions within microsecond windows, a skill set in short supply across most job shops.

Industry 4.0 Digital Threads Enable Predictive Manufacturing

Closed-loop platforms connect CAM programming parameters to real-time spindle power, vibration, and tool-wear sensors. Hexagon algorithms detect impending tool failure 15-20 minutes in advance and auto-adjust feed rates to hold surface quality within tolerance, mitigating scrap on fragile aerospace alloys. These solutions require dense sensor networks and high-throughput analytics, restricting adoption to plants where part value justifies the capital outlay.

Open-Source CAM Alternatives Challenge Commercial Pricing Models

FreeCAD PathWorkbench now outputs 2.5-axis G-code at no license cost, making it a credible entry-level choice for schools and micro-workshops. Commercial vendors counter by bundling AI-driven optimization and cloud collaboration, features that exceed the computing means of most community projects, yet must guard against basic modules edging toward commoditization.

Other drivers and restraints analyzed in the detailed report include:

- Ultra-Precision Packaging Lines Drive CAM Innovation

- EV Platform Localization Accelerates Precision Machining Demand

- Skills Gap in CNC Programming Constrains Market Expansion

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Cloud-hosted suites still represent a minority of the overall Computer Aided Manufacturing market, but their 10.9% CAGR through 2030 underscores an irreversible direction. Aerospace groups with plants on three continents rely on browser-based toolpath editing to hand off jobs overnight, trimming lead times by 20-25%. Defense contractors resist full migration because ITAR rules demand onsite data sovereignty; consequently, hybrid stacks local post-processors linked to cloud solvers form the bridge. Edge gateways retrofit older machines lacking OPC-UA or MTConnect, letting them stream encrypted data without controller replacement. Subscription models shift costs from capital budgets to operating expenses, a boon for small shops that previously deferred software upgrades. Cloud analytics also enable vendors to benchmark spindle utilization across an anonymized fleet, feeding predictive-maintenance dashboards that slash unscheduled downtime. As zero-trust architectures mature, even conservative sectors plan pilot migrations by 2027, suggesting the Computer Aided Manufacturing market will cross a psychological cloud-adoption threshold within the next budget cycle.

The on-premises base nevertheless remains indispensable for plants with air-gapped networks and proprietary alloy formulations. Vendors court these accounts by licensing digital-thread modules that reside behind the firewall yet sync selected metadata to a cloud vault for remote experts. This twin-track strategy stabilizes license renewals while boosting recurring revenue as customers graduate to hybrid analytics. Over time, discrete pricing between deployment modes may vanish as platform subscription tiers simply toggle cloud compute credits on or off. With cyber-insurance premiums now reflecting machine-tool network exposure, CFOs increasingly factor security accreditation into total cost of ownership. Consequently, the Computer-Aided Manufacturing market is evolving toward flexible tenancy rather than binary cloud-versus-on-site choices.

Automotive held 36.2% revenue in 2024, making it the anchor segment of the broader Compute Aided Manufacturing market. Yet the shift from internal-combustion machining to electric-vehicle parts challenges long-standing toolpath libraries. Battery tray milling demands thin-wall strategies that manage chatter while sustaining throughput in high-silicon aluminum. Meanwhile, aerospace and defense, though smaller, command premium licenses for 5-axis and composite machining. Medical-device firms adopt AI-assisted parameter tuning to meet ISO 13485 traceability, letting single-operator cells hit sub-10 µm tolerances without manual edits. Electronics and semiconductor packaging operators require thermal-aware drill sequencing to prevent copper delamination during 100,000-rpm via drilling, a niche that the latest CAM modules fulfill through physics solvers. Cross-pollination is rising: medical device shops replicate aerospace surface-finish routines, while automotive tiers import wafer-fab cleanliness protocols for battery modules, expanding the total addressable market of Computer Aided Manufacturing.

Diversification inside automaking is equally profound. Gigacasting of structural components eliminates dozens of stamped parts, but introduces massive CNC finishing of die-cast aluminum, requiring high material-removal rates and robust tool-life models. Suppliers investing in these cells demand software that auto-compensates for tool-wear drift across 20-hour unmanned shifts. In contrast, niche hypercar builders focus on carbon-fiber trim, using 5-axis routers and probe-based path updates each production cycle. Such divergence means one vertical now spans multiple CAM license tiers, ensuring that the Computer Aided Manufacturing market retains depth even if overall car volumes level off.

The Computer Aided Manufacturing Market Report is Segmented by Deployment Model (On-Premises, and Cloud-Based), End-User Industry (Aerospace and Defense, Automotive, Medical Devices, and More), Component (Software, and Services), Manufacturing Process (Milling, Turning, Drilling, and More), and Geography (North America, South America, Europe, Asia-Pacific, and More). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific's 47.1% share underscores its manufacturing heft, yet the region still wrestles with CNC protocol fragmentation that complicates plug-and-play interoperability. Chinese policy favors indigenous CAM algorithms tied to homegrown controllers, spurring parallel ecosystems that global vendors must bridge through dual-language post-processors and open-API tool libraries. Japan's machine OEMs integrate CAM directly into control firmware, shortening toolpath load times but locking customers into proprietary stacks. India's Production Linked Incentive schemes subsidize CAM licenses if tied to workforce upskilling, giving vendors a foothold in an emerging mid-market that could rival traditional giants by 2030.

North American users lead in cloud adoption, partly because the CHIPS Act funnels USD 52 billion into regional fabs that require distributed programming sooner than brick-and-mortar capacity is completed. Europe champions energy-efficient machining, mandating compressed-air reduction and tool reuse targets that CAM strategy simulators now model in kilowatt-hours per part. Data-sovereignty rules add friction, but tier-one suppliers accept localized data lakes in exchange for cross-plant optimization algorithms. These regional nuances ensure the Computer Aided Manufacturing market maintains broad diversification, cushioning it against localized downturns.

- Autodesk Inc.

- Siemens Digital Industries Software (Siemens AG)

- Dassault Systemes SE

- Hexagon AB (Hexagon Manufacturing Intelligence)

- CNC Software LLC (Mastercam)

- HCL Technologies Ltd.

- OPEN MIND Technologies AG

- SolidCAM Ltd.

- Cimatron Ltd.

- NTT Data Engineering Systems Corp.

- BobCAD-CAM Inc.

- MecSoft Corporation

- PTC Inc.

- ZWSOFT Co. Ltd.

- SmartCAMcnc Inc.

- GibbsCAM (3D Systems Corp.)

- Hypertherm Inc.

- SprutCAM Tech Ltd.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Rise in hybrid (subtractive + additive) machining centres

- 4.2.2 Expanding adoption of Industry 4.0-ready digital threads

- 4.2.3 Demand for ultra-precision parts in advanced packaging lines

- 4.2.4 Agile production needs for EV platform localisation

- 4.2.5 Shift toward cloud-native CAM for multi-site collaboration

- 4.2.6 Government re-shoring incentives for strategic sectors

- 4.3 Market Restraints

- 4.3.1 Proliferation of open-source / low-cost CAM alternatives

- 4.3.2 Persistent skills gap in NC programming and post-processing

- 4.3.3 IP-security concerns with cloud adoption in defence firms

- 4.3.4 Fragmented machine-tool controller standards

- 4.4 Industry Value Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Impact of Macroeconomic Factors

- 4.8 Porter's Five Forces Analysis

- 4.8.1 Bargaining Power of Suppliers

- 4.8.2 Bargaining Power of Buyers

- 4.8.3 Threat of New Entrants

- 4.8.4 Threat of Substitutes

- 4.8.5 Intensity of Competitive Rivalry

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Deployment Model

- 5.1.1 On-Premises

- 5.1.2 Cloud-Based

- 5.2 By End-User Industry

- 5.2.1 Aerospace and Defence

- 5.2.2 Automotive

- 5.2.3 Medical Devices

- 5.2.4 Energy and Utilities

- 5.2.5 Electronics and Semiconductor

- 5.2.6 Industrial Machinery

- 5.3 By Component

- 5.3.1 Software

- 5.3.2 Services

- 5.4 By Manufacturing Process

- 5.4.1 Milling

- 5.4.2 Turning

- 5.4.3 Drilling

- 5.4.4 Multi-Axis / 5-Axis

- 5.4.5 Additive Manufacturing

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 South America

- 5.5.2.1 Brazil

- 5.5.2.2 Argentina

- 5.5.2.3 Rest of South America

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Russia

- 5.5.3.5 Rest of Europe

- 5.5.4 Asia-Pacific

- 5.5.4.1 China

- 5.5.4.2 Japan

- 5.5.4.3 India

- 5.5.4.4 South Korea

- 5.5.4.5 South-East Asia

- 5.5.4.6 Rest of Asia-Pacific

- 5.5.5 Middle East and Africa

- 5.5.5.1 Middle East

- 5.5.5.1.1 Saudi Arabia

- 5.5.5.1.2 United Arab Emirates

- 5.5.5.1.3 Rest of Middle East

- 5.5.5.2 Africa

- 5.5.5.2.1 South Africa

- 5.5.5.2.2 Egypt

- 5.5.5.2.3 Rest of Africa

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Autodesk Inc.

- 6.4.2 Siemens Digital Industries Software (Siemens AG)

- 6.4.3 Dassault Systemes SE

- 6.4.4 Hexagon AB (Hexagon Manufacturing Intelligence)

- 6.4.5 CNC Software LLC (Mastercam)

- 6.4.6 HCL Technologies Ltd.

- 6.4.7 OPEN MIND Technologies AG

- 6.4.8 SolidCAM Ltd.

- 6.4.9 Cimatron Ltd.

- 6.4.10 NTT Data Engineering Systems Corp.

- 6.4.11 BobCAD-CAM Inc.

- 6.4.12 MecSoft Corporation

- 6.4.13 PTC Inc.

- 6.4.14 ZWSOFT Co. Ltd.

- 6.4.15 SmartCAMcnc Inc.

- 6.4.16 GibbsCAM (3D Systems Corp.)

- 6.4.17 Hypertherm Inc.

- 6.4.18 SprutCAM Tech Ltd.

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-Need Assessment