PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1687279

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1687279

Semiconductor Foundry - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

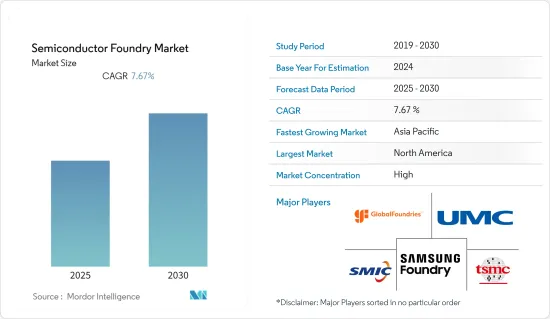

The Semiconductor Foundry Market is expected to register a CAGR of 7.67% during the forecast period.

Key Highlights

- Close partnerships between governments across borders, especially in South Korea and the United States, are anticipated to help the growth of the foundry market. Further, governments are encouraging companies to disclose semiconductor production information without revealing trade secrets to identify bottlenecks and prevent supply chain disruptions. The United States government asked firms like Samsung and Taiwan Semiconductor Manufacturing to voluntarily fill out a form detailing such information.

- Advanced analytics, when applied correctly, can drastically enhance operations and margins while simultaneously spurring growth. Despite this, many companies, including several semiconductor companies, have been slow to adopt these strategies.

- Owing to the increasing availability of high-speed connectivity, rising cloud adoption, and increasing use of data processing and analytics, the adoption of the Internet of Things (IoT) is growing steadily. For instance, as per Ericsson, there were 1.9 billion cellular IoT connections in the world in 2022, which is expected to grow to 5.5 billion in 2027, registering a CAGR of 19% over the period.

- Slowing innovation may lead to fewer new users adopting the technology, reducing the money chipmakers have for funding new developments. This may create a self-reinforcing cycle that steadily makes the economics of universal chips less attractive, slowing down technical progress.

- Despite the effects of the COVID-19 pandemic, the global semiconductor market observed robust growth in the latter half of 2020, which continued in 2021 as well. The industry was riddled with a high deficit and increasing demand, leading to a significant supply chain gap primarily attributed to the COVID-19 pandemic. The initial spread of the virus led to the shutting down or the reduction of foundry capacity utilization, fearing the decreasing demand for the chips across major sectors, like automotive. The diminished output led to a global shortage of semiconductors as the demand increased despite the initial estimates by semiconductor foundries.

Semiconductor Foundry Market Trends

Consumer Electronics and Communication to be the Largest End-user Industry

- Consumer electronics is one of the prominent application segments for the semiconductor foundry market. The growing adoption of consumer electronics devices, such as laptops, earphones, wearables, and smartphones, has propelled the segment's growth.

- Semiconductors are essential components of consumer electronics, enabling key features, such as advances in different applications like communication, computing, and others. In addition, the rapid development in the technology and size of consumer electronics has also been leading to the demand for advanced semiconductor technology.

- According to the Consumer Technology Association (CTA), in the United States, consumer technology industry revenue is projected to grow by 2.8% from 2021's impressive 9.6% growth over the year before. Strong demand for smartphones, health devices, automotive technologies, and streaming services would help the market to propel much of the projected revenue.

- In January 2023, Apple announced its plan to develop its new MacBook Air and iMac with the Apple M3 processor, built on a 3-nanometer process. In line with these plans, in December 2022, TSMC began mass production of its 3-nanometer chip process for the next generations of Mac, iPhone, and other Apple devices.

- Furthermore, the growth in wearables has also been leading to the adoption of new miniaturized chips, which propels the growth of semiconductor foundries that manufacture such chips in bulk. According to Cisco Systems, the number of connected wearable devices in North America reached 439 million in 2022 from 378.8 million in 2021. Globally, the number of connected wearable devices crossed 1 billion.

North America to Hold Significant Market Share

- The market for semiconductor manufacturing in North America is expanding significantly due to the growing use of semiconductor technology in connected devices and the automotive sector. The North American foundry market is predicted to be dominated by the United States because of the sector's intense competition from international and local competitors.

- Although America's position has faced numerous challenges throughout the years, it has always survived, owing to its resilience and capacity to move more quickly. Since the 1990s, the U.S. semiconductor sector has led the world in chip sales, holding close to 50% of the annual global market share, according to SIA. Additionally, American semiconductor companies continue to lead or be very competitive in research and development, design, and manufacturing process technology.

- Approximately 47% of the chips sold worldwide are created in the United States, according to the Semiconductor Industry Association (SIA). This discrepancy creates severe threats to the economy and national security of the United States, which is why both business insiders and politicians have recently started to demand the construction of semiconductor fabs in the country. Due to this, with capital investments for new fabs, Intel, Samsung, and TSMC have all expressed a willingness to grow their businesses in the United States, which will significantly support the country's future semiconductor manufacturing sector.

- For instance, Intel initially declared intentions to invest more than USD 20 billion in creating two new cutting-edge chip facilities in Ohio in January 2022. As part of Intel's IDM 2.0 plan, the investment will assist increase production in meeting the soaring demand for advanced semiconductors, powering a new generation of cutting-edge products from the business.

- In addition, TSMC declared in November 2022 that it will start producing 3-nanometer chips at its Arizona factory, where it now supplies Apple, in 2024. The Arizona factory of TSMC is a component of the Biden administration's plan to promote chip manufacturing in the country.

- Moreover, Canada is in a unique position, with economic, financial, and political systems, a highly-trained workforce, and a significant reputation internationally as a country that is open for business and is poised to take essential steps to emerge as a prominent region in the future semiconductor foundry landscape. IBM Microelectronics in Quebec still packages advanced computer chips and is now taking on new optical component technologies required for 5G.

Semiconductor Foundry Industry Overview

Owing to the consolidated nature of the market, foundries in the industry are competing intensely to gain access to fabless vendor deals to expand their presence and market share further. In addition, these players are increasingly investing in increasing their production capabilities.

The levels of market penetration for the existing top 5 vendors, TSMC, Samsung Electronics, UMC, GlobalFoundries, and SMIC, are significantly high, and these vendors are competing to gain a higher market share each year. In recent times, 5G and IoT have emerged as some of the significant drivers for units to be produced, and this is expected to be a strategic focus for foundries over the coming years. The level of innovation, time-to-market, and performance are the key terms by which the players differentiate themselves in the market. With growing consolidation, technological advancement, and geopolitical scenarios, the market studied is witnessing fluctuations.

In December 2022, Taiwan Semiconductor Manufacturing Co (TSMC) announced that it would more than triple its planned investment in Arizona, United States, to USD 40 billion from a previously announced USD 12 billion. The Arizona plants would produce 3-nm and 4-nm chips used for iPhone processors.

In December 2022, Samsung Electronics Ltd. announced plans to step up chip production capacity at its largest semiconductor fabrication plant in South Korea in 2023.

In October 2022, US Senator Patrick Leahy and GlobalFoundries announced the award of USD 30 million in federal funding to advance the development and production of next-generation gallium nitride (GaN) on silicon semiconductors at GF's Fab facility in Essex Junction, Vermont. The USD 30 million federal funding will enable GF to purchase tools and extend the development and implementation of 200 mm GaN wafer manufacturing in making chips for high-power applications, including electric vehicles, industrial motors, and energy applications.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Foundry Capacity Utilization Trends

- 4.4 Industry Value Chain Analysis

- 4.5 Impact of COVID-19 on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Optimization of Semiconductor Processes through Analytics

- 5.1.2 Automotive, IoT, and AI Sectors are Driving the Market

- 5.2 Market Challenges

- 5.2.1 Moores Law is about Reaching its Physical Limitation

- 5.3 Major Industry Partnerships

- 5.4 Foundry Trends Related to Semiconductor Products

6 MARKET SEGMENTATION

- 6.1 By Technology Node

- 6.1.1 10/7/5 nm

- 6.1.2 16/14 nm

- 6.1.3 20 nm

- 6.1.4 28 nm

- 6.1.5 45/40 nm

- 6.1.6 65 nm

- 6.1.7 Other Technology Nodes

- 6.2 By Application

- 6.2.1 Consumer Electronics and Communication

- 6.2.2 Automotive

- 6.2.3 Industrial

- 6.2.4 HPC

- 6.2.5 Other Applications

- 6.3 By Geography

- 6.3.1 North America

- 6.3.2 Europe, Middle East and Africa

- 6.3.3 Asia Pacific

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 TSMC Limited

- 7.1.2 Globalfoundries Inc.

- 7.1.3 United Microelectronics Corporation (UMC)

- 7.1.4 Semiconductor Manufacturing International Corporation (SMIC)

- 7.1.5 Samsung Electronics Co. Ltd (Samsung Foundry)

- 7.1.6 Dongbu Hitek Co. Ltd

- 7.1.7 Intel Corporation

- 7.1.8 Hua Hong Semiconductor Limited

- 7.1.9 Powerchip Technology Corporation

- 7.1.10 STMicroelectronics NV

- 7.1.11 Tower Semiconductor Ltd.

- 7.1.12 Vanguard International Semiconductor Corporation

- 7.1.13 X-FAB Silicon Foundries

- 7.1.14 NXP Semiconductors NV

- 7.1.15 Renesas Electronics Corporation

- 7.1.16 Microchip Technologies Inc.

- 7.1.17 Texas Instruments Inc.

8 OVERALL SEMICONDUCTOR (O-S-D AND IC) SALES BY IDMS DURING THE STUDY PERIOD AND KEY TRENDS AND DYNAMICS INFLUENCING THE GROWTH

9 FOUNDRY SALES BY IDMS DURING THE STUDY PERIOD

10 VENDOR MARKET SHARES BY TOP 5 IDMS BASED ON SEMICONDUCTOR SALES AND AN INDICATION OF THE PERCENTAGE SHARES BY CATEGORY (O-S-D VS IC) DURING THE STUDY PERIOD

11 VENDOR MARKET SHARE ANALYSIS - PUREPLAY COMPANIES

12 INVESTMENT ANALYSIS

13 FUTURE OF THE MARKET