Need help finding what you are looking for?

Contact Us

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1637904

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1637904

United States Ampoules Packaging - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

PUBLISHED:

PAGES: 120 Pages

DELIVERY TIME: 2-3 business days

SELECT AN OPTION

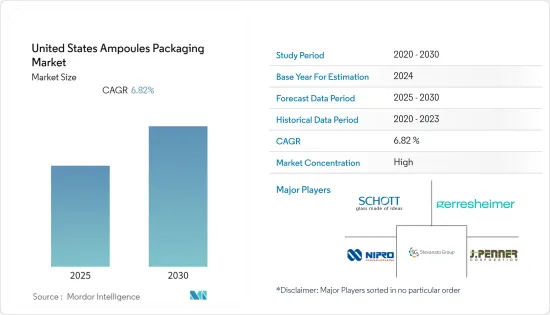

The United States Ampoules Packaging Market is expected to register a CAGR of 6.82% during the forecast period.

Key Highlights

- Ampoules are widely used in pharmaceutical and chemical laboratories to preserve and store medicinal fluids, capsules, and liquids. They have greatly influenced the shelf life of products as they prevent contamination and mix of medicines. Glass ampoules offer high transparency enabling easy inspection of their contents and higher protection as they are relatively impervious to moisture and air and chemically resistant to most medicinal products.

- The emergence of plastic ampoules in the market has been to counter some of the concerns relating to glass particles entering the contents during the breaking of the ampoules. This is expected to create an opportunity for plastic ampoules manufacturers and may be impacted by regulatory upgrades and standards in the respective nation.

- Several players are manufacturing custom-sized glass ampoules to cater to the swelling demand from various end-user industries. Straight stem ampoules and open funnel glass ampoules are manufactured for two different ampoules. Straight-stem ampoules are expected to witness increased demand owing to the growth of the vaccine market. The recent COVID-19 pandemic has provided further impetus to developing the fast-growing vaccine industry.

- Additionally, to maintain the properties of the medications, glass is a preferred material predominantly used in the pharmaceutical ampoule market. For instance, cytotoxic medicines, such as calcium folinate, are primarily packed in 3 mg/ml injection in the 10ml ampoule. Other significant areas of application for ampoules constitute the cosmetics/beauty industry. The growing market for high-quality elixirs and serum products for the face, eye area, hair, and hands have been a significant driver in the studied market.

- However, improper disposal of used ampoules will impede market expansion in the projected timeframe as glass ampoules are more expensive to manufacture and ship compared to plastic ones.

- The spread of COVID-19 negatively impacted the market due to supply chain difficulties brought on by delayed manufacturing. However, the situation drastically changed because more COVID vaccines were produced to counter the spread, which increased the demand for ampoules in the pharmaceutical business, which aided the market expansion during COVID-19.

US Ampoules Packaging Market Trends

High Commodity Value of Glass Resulting in High Recyclability

- Consumers in the United States are placing greater importance on sustainable, eco-friendly packaging solutions, which allows manufacturers to adopt glass ampoules over alternative packaging solutions. Companies such as Gerresheimer serve all market segments of the international pharmaceutical and healthcare industry, covering all aspects of beauty and hygiene.

- Pharmaceutical packaging accounts for a small proportion of waste because most of the packaging solutions use glass as a material. Additionally, glass packaging is 100% recyclable, which makes it a desirable packaging option from an environmental point of view. Moreover, colored glass, such as amber and red-colored glass, protects its contents from ultraviolet rays and specific wavelengths. Glass ampoules can easily sterilize using heat, making them suitable for pharmaceutical packaging.

- Furthermore, strict government regulations regarding the restrictions on the usage of PET material for pharmaceutical packaging further increase the attractiveness of glass packaging for the pharmaceutical industry.

- Also, according to the Glass Packaging Institute (GPI), using recycled glass in the manufacturing of new products reduces the consumption of raw materials, cuts emissions, extends the life of glass-making equipment such as furnaces, and saves energy. For instance, energy costs are reduced by around 2-3% for every 10% crushed recycled glass (cullet) used in the production process.

- The Glass Packaging Institute has set a target and plans to achieve a 50% recycling rate in the United States by 2030. However, the United States needs to catch up to the glass recycling rate, with around 37% of container glass being recycled. Europe has achieved a higher glass recycling rate of about 74%. Municipalities and Materials Recovery Facilities are attempting to increase the United States glass recycling rate through certifications and pilot programs.

- According to IQVIA, sales of brand-name drugs accounted for an 84% share of the money spent on medicines in the United States in 2021. The total amount spent on medicines reached about USD 574 billion in 2021. The spending increased year on year between 2012 and 2021, raising the total by USD 255 billion. The increased spending will undoubtedly impact the demand for ampoules in the projected time.

Pharmaceutical Industry will have a Significant Share

- Pharmaceutical glass ampoules demand is expected to increase due to the growing need for vaccine storage. Also, owing to the increasing health-related issues among the people living in the United States, manufacturing to meet the demand has increased dramatically. Even though many businesses faced negatively affected demand during the COVID-19 pandemic, few sectors, including the pharmaceutical glass industry, witnessed growth.

- Additionally, glassmakers such as Schott and Gerresheimer AG have reported increased demand from the pharmaceutical sector for ampoules, bottles, and vials to meet COVID-19 vaccine-related developments.

- Concerns such as light and ultraviolet penetration led to the growth in the use of ampoules in the pharmaceutical market. Ampoules offer better protection and security from various wavelengths of radiation and are mandatory for storing several medications. The moldable characteristic of plastic ampoules has stimulated ampoule manufacturing in multiple shapes and sizes for different uses in the pharmaceutical sector.

- Moreover, the choice of unit-dose parenteral packaging for consumers over multi-dose packaging has increased. Plastic ampoules provide fixed dosages to help pharmaceutical companies control costs by reducing drug overfill and other inefficiencies in the production process. Hence, plastic ampoules are especially advantageous for pharmaceutical companies dealing with costly drugs.

- Furthermore, the leading pharmaceutical companies in the United States hold a significant share of the global pharmaceutical markets, which is evident from the fact that the united states had 40.8% in 2021. For instance, according to IQVIA, In 2021, the United States held the position as the world's largest national pharmaceutical market, accounting for around 41% of all pharmaceutical expenditures. With a nearly 12% market share, China has established itself as the second-largest market.

US Ampoules Packaging Industry Overview

The United States Ampoules Packaging Market is consolidated due to the presence of few vendors in the market and the maturity status of the industry in the region. The market players are finding new ways, such as strategic partnerships or launching new products, to accelerate the development of ampoule packaging in the United States.

- January 2022: The Ritedose Corporation announced the development of and planned to commercialize the first new way to dispense single-dose liquid medications in two decades. After five years of research and development, the blow-fill-seal unit dosage technology creator introduced SuredoseRxTM, a simpler and more practical method for healthcare professionals to dispense and for patients to consume single doses of liquid drugs. The company is debuting three of its most popular liquid drugs in a new, single-dose, blow-fill-seal ampoule for generic liquid medications from Ritedose Corp. to reduce the risk of spills and contamination.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

Product Code: 48413

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Threat of New Entrants

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Bargaining Power of Suppliers

- 4.2.4 Threat of Substitute Products

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Industry Value Chain Analysis

- 4.4 Assessment of the Impact of COVID-19 on the Industry

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Demand for Tamper-proof Pharmaceutical Product Packaging

- 5.1.2 Commodity Value of Glass Increased with Recyclability

- 5.2 Market Restraints

- 5.2.1 Concerns Regarding Dumping of Used Ampoules

6 MARKET SEGMENTATION

- 6.1 By Material

- 6.1.1 Glass

- 6.1.2 Plastics

- 6.2 By End-user

- 6.2.1 Pharmaceutical

- 6.2.2 Personal Care and Cosmetic

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Schott AG

- 7.1.2 J. Penner Corporation

- 7.1.3 Gerresheimer AG

- 7.1.4 Stevanato Group

- 7.1.5 Accu-Glass, LLC

- 7.1.6 Nipro Pharma Packaging International NV

- 7.1.7 James Alexander Corporation

- 7.1.8 Wheaton Group (DWK Life Sciences, Inc.)

8 INVESTMENT ANALYSIS

9 FUTURE OF THE MARKET

Have a question?

SELECT AN OPTION

Have a question?

Questions? Please give us a call or visit the contact form.