Need help finding what you are looking for?

Contact Us

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1637919

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1637919

MEA Hazardous Location Connectors - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

PUBLISHED:

PAGES: 120 Pages

DELIVERY TIME: 2-3 business days

SELECT AN OPTION

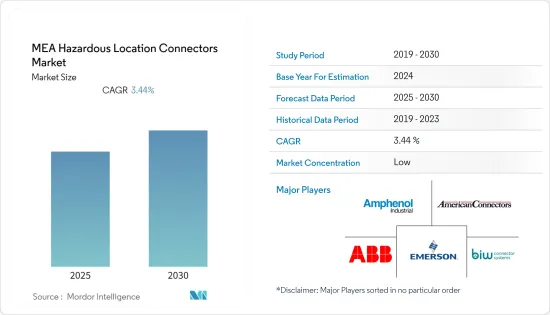

The MEA Hazardous Location Connectors Market is expected to register a CAGR of 3.44% during the forecast period.

Key Highlights

- Increasing industrial safety measures are driving the market's growth. The tools and equipment used in manufacturing can generate heat and flame, therefore increasing the risk of fire, especially in class I locations, because connectors play an essential role in preventing these types of explosions.

- Fiber optic connectors are in trend, as the use of fiber optic communications is becoming more common in improving safety and productivity. It substitutes hard-wiring methods, allowing users to safely make and break optic cables by providing wide operating temperature ranges, including sub-zero operation in the field with minimum downtime during the hazardous time.

- Increasing applications in the industrial sector are accelerating the market growth, as every application requires different connector designs, owing to the industry's need to withstand vibrations, extreme temperatures, and shocks.

- High-quality flexible connectors are used in the oil sectors by properly connecting all metallic non-current carrying equipment to prevent shock. At the same time, waterproof electrical connectors that are rubber molded are used in the wastewater treatment facility.

- Higher product installation and maintenance costs hinder the market's growth, as the PCB-mounted or wire-terminated connector has an additional cost associated with them that makes the set-up cost high.

MEA Hazardous Location Connectors Market Trends

Oil Refineries to have a significant growth

- As the demand for crude oil is growing rapidly, there is a need for safety equipment to prevent any fatality at hazardous locations in the refineries. Some areas of the refinery are inherently dangerous, with levels of explosive chemicals and gases present at all times. Explosion-proof equipment, such as connectors, can be installed inside an enclosure, preventing an internal explosion caused by the spark.

- Thomas & Betts products named mechanical grounding connectors, which are flexible connectors that are very effective by properly connecting all metallic non-current carrying equipment at the oil and gas facility, which significantly reduce the potential for electric shock and explosions.

- Vector Techlok clamp connectors of Freudenberg Oil & Gas Technologies are the most effective and economical pipe connection systems, which can withstand considerable bending moments and axial forces under pressure without leaking to prevent hazardous fatality or bolts becoming loose, which significantly reduces the maintenance costs and significant fatal incidents.

Zone 0 is expected to hold a significant share

- Zone 0 is an area where an explosive atmosphere has been continuously present for an extended period or may occur frequently. The areas classified as Zone 0 have specific characteristics. The continuous presence of flammable gases, vapors, liquids, or the company of such gases for long periods in a region is the condition for the Zone 0 classification.

- For instance, the vapor space above the liquid on the top of a tank or drum can and underground gas storage be classified as Zone 0. The ANSI/NEC classification method considers this environment a Class 1, Division 1 area. Zone 0 hazardous locations are primarily present in the oil and gas sector, owing to flammable gases like natural gases in the industry. The chemical and petroleum industry also has a relatively high presence of Zone 0, owing to the nature of the processes.

- The explosive area in the zone is estimated to be present for more than 1000 hr/year or greater than 10%. These values aid in the determination of safe areas from unsafe areas in the industry.

- The expansion in the oil and gas industry is expected to develop space for the studied market. Additionally, the growing safety concerns regarding incidents like natural gas leaks and the increasing adoption of automation tools for continuous monitoring of the underground gas storage and pipelines are expected to fuel the demand for hazardous location connectors in the Middle East and Africa Region.

MEA Hazardous Location Connectors Industry Overview

The Middle East and Africa Hazardous Location Connectors Market are less concentrated, with only a few prominent companies like American Connectors Inc., Amphenol Industrial Products Group, Thomas and Betts (ABB Group), etc., holding a significant share of the market. The companies in the region are forming multiple partnerships and mergers to increase their market share.

- February 2022 - ITT BIW Connector Systems announced its expanded and redesigned aircraft component line with five new valves and actuators, providing customers with solutions to control fluid handling valves used in fuel, hydraulic, water, and environmental control systems in the aerospace and defense market.

- November 2021 - ITT BIW Connector Systems introduced its ruggedized, modular circular series Veam MOVE - MOD. The flexible design delivers signal, power, and data in a single connector by utilizing a range of snap-in modules with various contact layouts to match individual system requirements.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

Product Code: 48587

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Buyers

- 4.2.2 Bargaining Power of Suppliers

- 4.2.3 Threat of New Entrants

- 4.2.4 Degree of Competition

- 4.2.5 Threat of Substitute Products

- 4.3 Industry Value Chain Analysis

- 4.4 Assessment Of Covid-19 Impact

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Rising Industrial Safety Measures

- 5.1.2 Increasing Applications in the Industrial Sector and Reducing Costs

- 5.1.3 Growing Awareness among Industry Personnel

- 5.2 Market Restraints

- 5.2.1 Complexity of Standards

- 5.2.2 Product Installation and Maintenance Costs

6 MARKET SEGMENTATION

- 6.1 By Class

- 6.1.1 Class I

- 6.1.2 Class II

- 6.1.3 Class III

- 6.2 By Hazardous Zones

- 6.2.1 Zone 0

- 6.2.2 Zone 1

- 6.2.3 Zone 2

- 6.3 By Applications

- 6.3.1 Food & Beverage Processing

- 6.3.2 Oil & Gas Production

- 6.3.3 Oil Refineries

- 6.3.4 Petrochemical Refineries

- 6.3.5 Pharmaceutical Manufacturing

- 6.3.6 Wastewater Treatment Facilities

- 6.3.7 Other Applications

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 American Connectors, Inc.

- 7.1.2 Thomas & Betts ( ABB Group)

- 7.1.3 ITT BIW Connector Systems

- 7.1.4 Emersion Industrial Automation

- 7.1.5 Amphenol Industrial Products Group

- 7.1.6 Hubbell-Killark

- 7.1.7 Crouse-Hinds (Eaton)

- 7.1.8 Vantage Technology

8 INVESTMENT ANALYSIS

9 FUTURE OF THE MARKET

Have a question?

SELECT AN OPTION

Have a question?

Questions? Please give us a call or visit the contact form.