PUBLISHER: MarketsandMarkets | PRODUCT CODE: 1780342

PUBLISHER: MarketsandMarkets | PRODUCT CODE: 1780342

Metalized Flexible Packaging Market by Material Type, Structure, Packaging Type, End-Use Industry & Region - Global Forecast to 2030

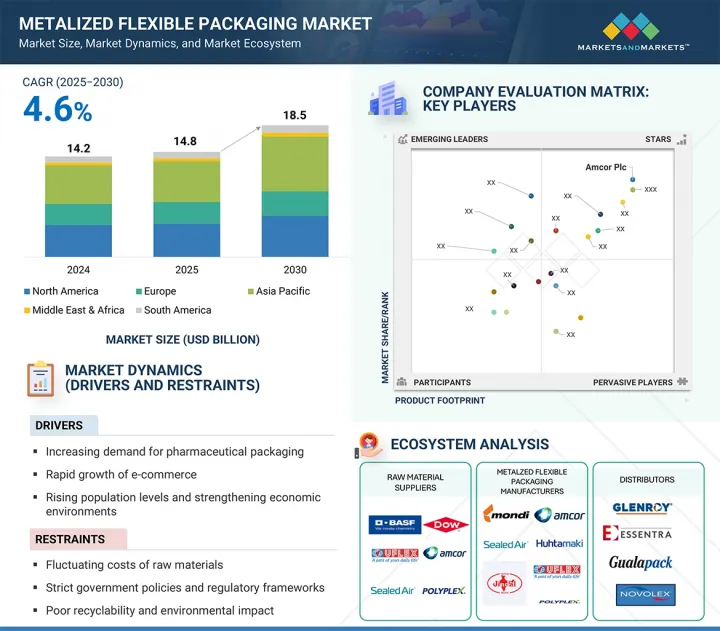

The market for metalized flexible is estimated to grow from USD 14.8 billion in 2025 to USD 18.5 billion in 2030 at a CAGR of 4.6%.

| Scope of the Report | |

|---|---|

| Years Considered for the Study | 2021-2030 |

| Base Year | 2024 |

| Forecast Period | 2025-2030 |

| Units Considered | Value (USD Million) and Volume (Kiloton) |

| Segments | Material Type, Structure, Packaging Type, End-use Industry, and Region |

| Regions covered | North America, Asia Pacific, Europe, Middle East & Africa, and South America |

The metalized flexible packaging industry is likely to expand during the forecast period due to the increasing demand for lightweight yet high-barrier packaging that extends the shelf life of products, the growth of e-commerce and direct-to-consumer retail markets, the rising popularity of more attractive and user-friendly packaging in the food, personal care, and pet food segments, and the growing use in pharmaceuticals that protect against moisture, oxygen, and light. Furthermore, emerging economies are characterized by high consumption, as their disposable incomes have risen and their lifestyles are evolving.

By material type, Alox/SiOx PET accounted for the fastest-growing segment during the forecast period.

Alox/SiOx PET is the fastest-growing type of material in the metallized flexible packaging market, as it provides an exceptional high barrier to oxygen, moisture, and fragrances compared to traditional aluminum foil, while still maintaining flexibility, clarity, and recyclability. Its ultra-thin inorganic coatings applied to PET allow brands to achieve product visibility, high-quality graphics, and structural strength, as seen in stand-up pouches and sachets. This combination of aesthetics, shelf performance, and sustainable pricing is poised to meet the growing consumer expectations and increasingly stringent requirements set by regulatory bodies regarding food safety, extended shelf life, and packaging systems that align with the circular economy, where aerated packaging structures, such as Alox/SiOx PET, become the preferred future-proof flexible packaging material.

By structure, the mono-extruded structures segment accounted for the fastest-growing segment during the forecast period.

The fastest-growing segment within the metalized flexible packaging market is mono-extruded structures, as they effectively combine high-barrier capabilities with full recyclability in a single material film. Brands achieve the same level of protection against moisture and oxygen, and against light, as a traditional laminate, due to the metallization of a mono-layer base. Additionally, recycling is simplified and aligned with consumer expectations compared to a traditional laminate; the only difference in effectiveness lies in moisture resistance. Mono-extruded films are also cost-effective to manufacture and versatile for various packaging forms, such as pouches, sachets, and lidding, making them an ideal choice for cost and convenience in food, pet care, personal care, and pharmaceutical packaging.

By packaging type, the pouches segment was the fastest-growing segment during the forecast period

Pouches are performing exceptionally well as the packaging format with the most active growth in the metalized flexible packaging industry since pouches present an all-in-one high barrier functionality, as well as the benefit of convenience, product sales attractiveness, versatility, and efficiency to the consumer. Their thin portable design makes shipping and storage cheaper, and aspects such as zip-locks, tear notches, and spouts are designed to be able to meet the current consumer trend of portable use with no mess. The metalised coating adds gloss and visual appeal on-shelf and in e-commerce unboxing, and its versatile applications in food, pet care, personal care, and nutraceutical industries have led to its swift market penetration throughout the world.

By end-use industry, the pet food segment accounted for the highest CAGR during the forecast period

The fastest-growing end-use in the metalized flexible packaging market is pet food, as it has been reported that pet owners are actively seeking high-quality, convenient, and smelly-free packaging that retains pet treats, food in wet form, and supplements so that they do not spoil and metalized stand-up pouches that reseal address these requirements to ensure there is good barrier protection, high portability, and shelf presence, both in-store and online.

By region, Asia Pacific is projected to account for the highest CAGR during the forecast period.

The fastest growing metalized flexible packaging market is Asia Pacific, driven by rapid urbanization and a surging middle-income consumer base that creates high demand for packaged and convenience food, personal care, pharmaceutical, and pet care products. This trend is further supported by the remarkable rise of e-commerce and DTC retail, investments in regional manufacturing infrastructure, and the development of metalized packaging designed to protect while being lightweight and appealing to various industries.

- By Company Type: Tier 1: 25%, Tier 2: 42%, Tier 3: 33%

- By Designation: C Level: 20%, Director Level: 30%, Others: 50%

- By Region: North America: 20%, Europe: 10%, Asia Pacific: 40%, Middle East & Africa: 20%, and South America: 10%.

Companies Covered:

Amcor plc (Switzerland), Mondi Plc (UK), Sealed Air Corporation (US), Huhtamaki Oyj (Finland), Transcontinental Inc. (Canada), and Polyplex Corporation Ltd. (India) are some key players in the metalized flexible packaging market.

Research Coverage

The market study examines the metalized flexible packaging market across various segments. It aims to estimate the market size and growth potential across different segments based on material type, structure, packaging type, end-use industry, and region. Additionally, the study includes a thorough competitive analysis of key players, their company profiles, notable observations regarding their products and business offerings, recent developments they have undertaken, and key growth strategies they have adopted to enhance their position in the metalized flexible packaging market.

Key Benefits of Buying the Report

The report is expected to assist market leaders and new entrants in this sector by providing the closest approximations of the revenue figures for the overall metalized flexible packaging market, as well as its segments and sub-segments. This report aims to help stakeholders comprehend the competitive landscape of the market, acquire insights to enhance their business positions, and plan effective go-to-market strategies. Additionally, the report seeks to help stakeholders gauge the market's pulse and provide information on the key drivers, challenges, and opportunities within the market.

The report provides insights on the following pointers:

- Analysis of key drivers (rapid growth of e-commerce), restraints (poor recyclability and environmental impact), opportunities (expansion of pet food packaging), and challenges (intensifying competition from emerging high-barrier alternatives) influencing the growth of the metalized flexible packaging market.

- Product Development/Innovation: Detailed insights on upcoming technologies, research & development activities, and new product & service launches in the metalized flexible packaging market

- Market Development: Comprehensive information about profitable markets - the report analyses the metalized flexible packaging market across varied regions

Market Diversification: Exhaustive information about new products & services, untapped geographies, recent developments, and investments in the metalized flexible packaging market

- Competitive Assessment: In-depth assessment of market shares, growth strategies, and service offerings of leading players like as Amcor plc (Switzerland), Mondi Plc (UK), Sealed Air Corporation (US), Huhtamaki Oyj (Finland), and Transcontinental Inc. (Canada) in the metalized flexible packaging market. The report also helps stakeholders understand the pulse of the metalized flexible packaging market and provides them with information on key market drivers, restraints, challenges, and opportunities.

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 STUDY OBJECTIVES

- 1.2 MARKET DEFINITION

- 1.3 STUDY SCOPE

- 1.3.1 METALIZED FLEXIBLE PACKAGING MARKET SEGMENTATION AND REGIONAL SCOPE

- 1.3.2 INCLUSIONS AND EXCLUSIONS

- 1.3.3 YEARS CONSIDERED

- 1.3.4 CURRENCY CONSIDERED

- 1.3.5 UNITS CONSIDERED

- 1.4 STAKEHOLDERS

- 1.5 LIMITATIONS

- 1.6 SUMMARY OF CHANGES

2 RESEARCH METHODOLOGY

- 2.1 RESEARCH DATA

- 2.1.1 SECONDARY DATA

- 2.1.1.1 Critical secondary inputs

- 2.1.1.2 Key data from secondary sources

- 2.1.2 PRIMARY DATA

- 2.1.2.1 Critical primary inputs

- 2.1.2.2 Key primary participants

- 2.1.2.3 Key data from primary sources

- 2.1.2.4 Key industry insights

- 2.1.2.5 Breakdown of interviews with experts

- 2.1.1 SECONDARY DATA

- 2.2 BASE NUMBER CALCULATION

- 2.2.1 ESTIMATION OF METALIZED FLEXIBLE PACKAGING MARKET SIZE BASED ON MARKET SHARE ANALYSIS

- 2.2.2 SUPPLY-SIDE APPROACH-1

- 2.2.3 SUPPLY-SIDE APPROACH-2

- 2.2.4 SUPPLY-SIDE APPROACH-3

- 2.3 FACTOR ANALYSIS

- 2.3.1 INTRODUCTION

- 2.3.2 DEMAND-SIDE ANALYSIS

- 2.3.3 SUPPLY-SIDE ANALYSIS

- 2.4 MARKET SIZE ESTIMATION

- 2.4.1 MARKET SIZE ESTIMATION METHODOLOGY: BOTTOM-UP APPROACH

- 2.4.2 MARKET SIZE ESTIMATION METHODOLOGY: TOP-DOWN APPROACH

- 2.5 DATA TRIANGULATION

- 2.6 RESEARCH ASSUMPTIONS

- 2.7 RESEARCH LIMITATIONS

- 2.8 RESEARCH LIMITATIONS AND RISK ASSESSMENT

3 EXECUTIVE SUMMARY

4 PREMIUM INSIGHTS

- 4.1 ATTRACTIVE OPPORTUNITIES FOR PLAYERS IN METALIZED FLEXIBLE PACKAGING MARKET

- 4.2 METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE

- 4.3 METALIZED FLEXIBLE PACKAGING MARKET, BY STRUCTURE

- 4.4 METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE

- 4.5 METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY

- 4.6 ASIA PACIFIC: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY AND COUNTRY

- 4.7 METALIZED FLEXIBLE PACKAGING MARKET, BY KEY COUNTRY

5 MARKET OVERVIEW

- 5.1 INTRODUCTION

- 5.2 MARKET DYNAMICS

- 5.2.1 DRIVERS

- 5.2.1.1 Rising population and strengthening economies

- 5.2.1.2 Increasing demand for pharmaceutical packaging

- 5.2.1.3 Rapid growth of e-commerce

- 5.2.1.4 Rising demand for easy-to-use food packaging solutions

- 5.2.2 RESTRAINTS

- 5.2.2.1 Fluctuating costs of raw materials

- 5.2.2.2 Stringent government policies and regulatory frameworks

- 5.2.3 OPPORTUNITIES

- 5.2.3.1 Increasing demand for packaging personal care and cosmetics products

- 5.2.3.2 Growing demand for pet food packaging

- 5.2.3.3 Sustainable and new metalized flexible packaging solutions

- 5.2.4 CHALLENGES

- 5.2.4.1 Poor recyclability and environmental impact

- 5.2.4.2 Supply chain disruptions

- 5.2.1 DRIVERS

- 5.3 TRENDS/DISRUPTIONS IMPACTING CUSTOMER BUSINESS

- 5.4 ECOSYSTEM ANALYSIS

- 5.5 VALUE CHAIN ANALYSIS

- 5.6 REGULATORY LANDSCAPE

- 5.6.1 REGULATORY LANDSCAPE

- 5.6.1.1 Regulatory bodies, government agencies, and other organizations

- 5.6.2 KEY REGULATIONS

- 5.6.2.1 NSF/ANSI standards

- 5.6.1 REGULATORY LANDSCAPE

- 5.7 PRICING ANALYSIS

- 5.7.1 AVERAGE SELLING PRICE TREND OF KEY PLAYERS, BY END-USE INDUSTRY,2024

- 5.7.2 AVERAGE SELLING PRICE TREND, BY REGION, 2021-2030

- 5.8 TRADE ANALYSIS

- 5.8.1 EXPORT SCENARIO (HS CODE 7607)

- 5.8.2 IMPORT SCENARIO (HS CODE 7607)

- 5.9 TECHNOLOGY ANALYSIS

- 5.9.1 KEY TECHNOLOGIES

- 5.9.1.1 Lamination

- 5.9.1.2 Mono-extrusion

- 5.9.1.3 Co-extrusion

- 5.9.2 COMPLEMENTARY TECHNOLOGIES

- 5.9.2.1 High-barrier coatings

- 5.9.2.2 Laser scoring and micro-perforation

- 5.9.3 ADJACENT TECHNOLOGIES

- 5.9.3.1 Smart packaging

- 5.9.1 KEY TECHNOLOGIES

- 5.10 PATENT ANALYSIS

- 5.10.1 INTRODUCTION

- 5.11 CASE STUDY ANALYSIS

- 5.11.1 NEW BLISTER PACKAGING TECHNOLOGY DEVELOPED FOR GSK

- 5.11.2 CELPLAST DEVELOPED LIGHTER, RECYCLABLE, HIGH-BARRIER PACKAGING SOLUTIONS TO MEET INDUSTRY DEMAND

- 5.12 KEY STAKEHOLDERS AND BUYING CRITERIA

- 5.12.1 KEY STAKEHOLDERS IN BUYING PROCESS

- 5.12.2 BUYING CRITERIA

- 5.13 KEY CONFERENCES AND EVENTS, 2025-2026

- 5.14 INVESTMENT AND FUNDING SCENARIO

- 5.15 IMPACT OF GEN AI/AI ON METALIZED FLEXIBLE PACKAGING MARKET

- 5.15.1 INTRODUCTION

- 5.16 PORTER'S FIVE FORCES ANALYSIS

- 5.16.1 THREAT OF NEW ENTRANTS

- 5.16.2 THREAT OF SUBSTITUTES

- 5.16.3 BARGAINING POWER OF SUPPLIERS

- 5.16.4 BARGAINING POWER OF BUYERS

- 5.16.5 INTENSITY OF COMPETITIVE RIVALRY

- 5.17 MACROECONOMIC ANALYSIS

- 5.17.1 INTRODUCTION

- 5.17.2 GDP TRENDS AND FORECASTS, 2021-2028

- 5.18 IMPACT OF 2025 US TARIFF ON METALIZED FLEXIBLE PACKAGING MARKET

- 5.18.1 INTRODUCTION

- 5.18.2 KEY TARIFF RATES

- 5.18.3 PRICE IMPACT ANALYSIS

- 5.18.4 IMPACT ON COUNTRY/REGION

- 5.18.4.1 US

- 5.18.4.2 China

- 5.18.4.3 Europe

- 5.18.5 IMPACT ON END-USE INDUSTRIES

6 METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY

- 6.1 INTRODUCTION

- 6.2 FOOD

- 6.2.1 GROWTH OF E-COMMERCE SECTOR TO DRIVE MARKET

- 6.3 BEVERAGE

- 6.3.1 INCREASING NEED FOR LONGER SHELF LIFE PACKAGING TO FUEL GROWTH

- 6.4 PERSONAL CARE

- 6.4.1 VERSATILITY AND PRODUCT PROTECTION FROM DAMAGE DUE TO MOISTURE OR GAS TO BOOST MARKET

- 6.5 PHARMACEUTICALS

- 6.5.1 INCREASING AWARENESS ABOUT HEALTH AND HEALTHCARE SPENDING TO FUEL MARKET

- 6.6 PET FOOD

- 6.6.1 DEMAND FOR RELIABLE, EFFECTIVE PACKAGING SOLUTIONS THAT PRESERVE QUALITY AND SAFETY TO PROPEL MARKET

- 6.7 OTHER END-USE INDUSTRIES

7 METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE

- 7.1 INTRODUCTION

- 7.2 ALUMINUM-FOIL-BASED FLEXIBLE PACKAGING

- 7.2.1 GOOD THERMAL AND MECHANICAL PROPERTIES TO DRIVE MARKET

- 7.2.2 ALUMINUM PAPER

- 7.2.3 ALUMINUM PAPER POLYMER

- 7.2.4 ALUMINUM POLYMER

- 7.3 METALIZED FILM FLEXIBLE PACKAGING

- 7.3.1 GROWING DEMAND FOR READY-TO-EAT FOOD AND LONGER SHELF LIFE OF PACKAGED PRODUCTS TO BOOST MARKET

- 7.3.2 MET PP/PE

- 7.3.3 MET PET/PE

- 7.3.4 OTHER METALIZED FILM PACKAGING

- 7.4 ALOX/SIOX PP

- 7.4.1 INCREASING DEMAND FOR SUSTAINABLE AND RECYCLABLE PACKAGING MATERIALS TO PROPEL MARKET

- 7.5 ALOX/SIOX PET

- 7.5.1 BARRIER PERFORMANCE AND SUSTAINABILITY TO DRIVE GROWTH

- 7.6 OTHER ALOX/SIOX METALIZED FLEXIBLE PACKAGING

8 METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE

- 8.1 INTRODUCTION

- 8.2 POUCHES

- 8.2.1 RISING POPULARITY OF READY-TO-EAT FOODS TO DRIVE MARKET

- 8.3 BAGS

- 8.3.1 INCREASING DEMAND FROM HEALTHCARE AND FOOD SECTORS TO PROPEL MARKET

- 8.4 WRAPS

- 8.4.1 HIGH DEMAND FOR FLEXIBLE PLASTIC PACKAGING TO BOOST MARKET

- 8.5 ROLLSTOCK

- 8.5.1 LEAK-PROOF AND HIGH OXYGEN BARRIER PROPERTIES TO FUEL MARKET

- 8.6 OTHER PACKAGING TYPES

9 METALIZED FLEXIBLE PACKAGING MARKET, BY STRUCTURE

- 9.1 INTRODUCTION

- 9.2 LAMINATED STRUCTURES

- 9.2.1 HIGH BARRIER PROPERTIES TO DRIVE MARKET

- 9.3 MONO-EXTRUDED STRUCTURES

- 9.3.1 SUSTAINABILITY AND RECYCLABILITY TO BOOST MARKET

- 9.4 OTHER STRUCTURES

10 METALIZED FLEXIBLE PACKAGING MARKET, BY REGION

- 10.1 INTRODUCTION

- 10.2 ASIA PACIFIC

- 10.2.1 CHINA

- 10.2.1.1 Strong pharmaceutical production base to drive market

- 10.2.2 INDIA

- 10.2.2.1 Rising e-commerce industry to fuel market

- 10.2.3 JAPAN

- 10.2.3.1 Growing demand for generic drugs to drive market

- 10.2.4 SOUTH KOREA

- 10.2.4.1 Implementation of rigorous standards and rules to boost market

- 10.2.5 REST OF ASIA PACIFIC

- 10.2.1 CHINA

- 10.3 EUROPE

- 10.3.1 GERMANY

- 10.3.1.1 Increasing manufacturing activities and government initiatives toward circular economy to boost market

- 10.3.2 UK

- 10.3.2.1 Growth of healthcare industry to propel market

- 10.3.3 FRANCE

- 10.3.3.1 Surge in retail sales of packaged foods and growing health concerns to fuel market

- 10.3.4 ITALY

- 10.3.4.1 Rising demand from retail and healthcare industries to drive growth

- 10.3.5 SPAIN

- 10.3.5.1 Growing demand from food & beverage industry to fuel market

- 10.3.6 RUSSIA

- 10.3.6.1 Increasing awareness and need for eco-friendly solutions to boost market

- 10.3.7 REST OF EUROPE

- 10.3.1 GERMANY

- 10.4 NORTH AMERICA

- 10.4.1 US

- 10.4.1.1 Rising e-commerce sector to drive market

- 10.4.2 CANADA

- 10.4.2.1 Increasing demand for convenient, lightweight, and sustainable packaging solutions to propel growth

- 10.4.3 MEXICO

- 10.4.3.1 Increasing demand for convenience food and changing lifestyles to fuel growth

- 10.4.1 US

- 10.5 SOUTH AMERICA

- 10.5.1 BRAZIL

- 10.5.1.1 Rising demand from food processing industry to drive market

- 10.5.2 ARGENTINA

- 10.5.2.1 Rising consumption of packaged meat products to propel market

- 10.5.3 REST OF SOUTH AMERICA

- 10.5.1 BRAZIL

- 10.6 MIDDLE EAST & AFRICA

- 10.6.1 GCC COUNTRIES

- 10.6.1.1 UAE

- 10.6.1.1.1 Rapidly expanding food and beverage industry to drive market

- 10.6.1.2 Saudi Arabia

- 10.6.1.2.1 Rising urban population and changing consumer preferences to fuel demand

- 10.6.1.3 Rest of GCC countries

- 10.6.1.1 UAE

- 10.6.2 SOUTH AFRICA

- 10.6.2.1 Growth of pharmaceutical industry to boost market

- 10.6.3 REST OF MIDDLE EAST & AFRICA

- 10.6.1 GCC COUNTRIES

11 COMPETITIVE LANDSCAPE

- 11.1 OVERVIEW

- 11.2 KEY PLAYER STRATEGIES/RIGHT TO WIN

- 11.3 REVENUE ANALYSIS, 2020-2024

- 11.4 MARKET SHARE ANALYSIS, 2024

- 11.5 COMPANY VALUATION AND FINANCIAL METRICS

- 11.5.1 COMPANY VALUATION

- 11.5.2 FINANCIAL METRICS

- 11.6 BRAND/PRODUCT COMPARISON

- 11.7 COMPANY EVALUATION MATRIX: KEY PLAYERS, 2024

- 11.7.1 STARS

- 11.7.2 EMERGING LEADERS

- 11.7.3 PERVASIVE PLAYERS

- 11.7.4 PARTICIPANTS

- 11.7.5 COMPANY FOOTPRINT: KEY PLAYERS, 2024

- 11.7.5.1 Company footprint

- 11.7.5.2 Region footprint

- 11.7.5.3 Structure footprint

- 11.7.5.4 Packaging type footprint

- 11.7.5.5 End-use industry footprint

- 11.8 COMPANY EVALUATION MATRIX: STARTUPS/SMES, 2024

- 11.8.1 PROGRESSIVE COMPANIES

- 11.8.2 RESPONSIVE COMPANIES

- 11.8.3 DYNAMIC COMPANIES

- 11.8.4 STARTING BLOCKS

- 11.8.5 COMPETITIVE BENCHMARKING: STARTUPS/SMES, 2024

- 11.8.5.1 Detailed list of key startups/SMEs

- 11.8.5.2 Competitive benchmarking of key startups/SMEs

- 11.9 COMPETITIVE SCENARIO

- 11.9.1 PRODUCT LAUNCHES

- 11.9.2 DEALS

- 11.9.3 EXPANSIONS

12 COMPANY PROFILES

- 12.1 KEY PLAYERS

- 12.1.1 AMCOR PLC

- 12.1.1.1 Business overview

- 12.1.1.2 Products/Solutions/Services offered

- 12.1.1.3 Recent developments

- 12.1.1.3.1 Product launches

- 12.1.1.3.2 Deals

- 12.1.1.3.3 Expansions

- 12.1.1.4 MnM view

- 12.1.1.4.1 Right to win

- 12.1.1.4.2 Strategic choices

- 12.1.1.4.3 Weaknesses and competitive threats

- 12.1.2 MONDI

- 12.1.2.1 Business overview

- 12.1.2.2 Products/Solutions/Services offered

- 12.1.2.3 Recent developments

- 12.1.2.3.1 Deals

- 12.1.2.3.2 Expansions

- 12.1.2.4 MnM view

- 12.1.2.4.1 Right to win

- 12.1.2.4.2 Strategic choices

- 12.1.2.4.3 Weaknesses and competitive threats

- 12.1.3 SEALED AIR CORPORATION

- 12.1.3.1 Business overview

- 12.1.3.2 Products/Solutions/Services offered

- 12.1.3.3 Recent developments

- 12.1.3.3.1 Deals

- 12.1.3.4 MnM view

- 12.1.3.4.1 Right to win

- 12.1.3.4.2 Strategic choices

- 12.1.3.4.3 Weaknesses and competitive threats

- 12.1.4 HUHTAMAKI OYJ

- 12.1.4.1 Business overview

- 12.1.4.2 Products/Solutions/Services offered

- 12.1.4.3 Recent developments

- 12.1.4.3.1 Deals

- 12.1.4.4 MnM view

- 12.1.4.4.1 Right to win

- 12.1.4.4.2 Strategic choices

- 12.1.4.4.3 Weaknesses and competitive threats

- 12.1.5 TOPPAN HOLDINGS INC.

- 12.1.5.1 Business overview

- 12.1.5.2 Products/Solutions/Services offered

- 12.1.5.3 Recent developments

- 12.1.5.3.1 Deals

- 12.1.5.4 MnM view

- 12.1.5.4.1 Right to win

- 12.1.5.4.2 Strategic choices

- 12.1.5.4.3 Weaknesses and competitive threats

- 12.1.6 TRANSCONTINENTAL INC.

- 12.1.6.1 Business overview

- 12.1.6.2 Products/Solutions/Services offered

- 12.1.6.3 Recent developments

- 12.1.6.3.1 Product launches

- 12.1.6.3.2 Deals

- 12.1.6.3.3 Expansions

- 12.1.6.4 MnM view

- 12.1.7 POLYPLEX CORPORATION LIMITED

- 12.1.7.1 Business overview

- 12.1.7.2 Products/Solutions/Services offered

- 12.1.7.3 MnM view

- 12.1.8 COSMO FIRST LIMITED

- 12.1.8.1 Business overview

- 12.1.8.2 Products/Solutions/Services offered

- 12.1.8.3 Recent developments

- 12.1.8.3.1 Deals

- 12.1.8.4 MnM view

- 12.1.9 UFLEX LIMITED

- 12.1.9.1 Business overview

- 12.1.9.2 Products/Solutions/Services offered

- 12.1.9.3 Recent developments

- 12.1.9.3.1 Product launches

- 12.1.9.4 MnM view

- 12.1.10 JPFL FILMS PRIVATE LIMITED

- 12.1.10.1 Business overview

- 12.1.10.2 Products/Solutions/Services offered

- 12.1.10.3 Recent developments

- 12.1.10.3.1 Deals

- 12.1.10.4 MnM view

- 12.1.1 AMCOR PLC

- 12.2 OTHER PLAYERS

- 12.2.1 ESTER INDUSTRIES LIMITED

- 12.2.2 CONSTANTIA FLEXIBLES

- 12.2.3 TAGHLEEF INDUSTRIES

- 12.2.4 POLINAS

- 12.2.5 DUNMORE

- 12.2.6 GR (SHANDONG) NEW MATERIAL CO.,LTD.

- 12.2.7 SHANGHAI RUITU NEW MATERIALS TECHNOLOGY CO., LTD.

- 12.2.8 XIAMEN CHANGSU INDUSTRIAL CO., LTD.

- 12.2.9 CELPLAST METALLIZED PRODUCTS LIMITED

- 12.2.10 ULTIMET FILMS LIMITED

- 12.2.11 ACCRUED PLASTIC LTD.

- 12.2.12 ALL FOILS, INC.

- 12.2.13 MANUCOR SPA

- 12.2.14 SRF LIMITED

- 12.2.15 KAVERI METALLISING & COATING IND. PRIVATE LIMITED

13 ADJACENT AND RELATED MARKET

- 13.1 INTRODUCTION

- 13.2 LIMITATIONS

- 13.2.1 FLEXIBLE PACKAGING MARKET

- 13.2.1.1 Market definition

- 13.2.1.2 Flexible packaging market, by material

- 13.2.1.3 Flexible packaging market, by packaging type

- 13.2.1.4 Flexible packaging market, by printing technology

- 13.2.1.5 Flexible packaging market, by application

- 13.2.1.6 Flexible packaging market, by region

- 13.2.1 FLEXIBLE PACKAGING MARKET

14 APPENDIX

- 14.1 DISCUSSION GUIDE

- 14.2 CUSTOMIZATION OPTIONS

- 14.3 RELATED REPORTS

- 14.4 KNOWLEDGESTORE: MARKETSANDMARKETS' SUBSCRIPTION PORTAL

- 14.5 AUTHOR DETAILS

List of Tables

- TABLE 1 ROLES OF COMPANIES IN METALIZED FLEXIBLE PACKAGING ECOSYSTEM

- TABLE 2 NORTH AMERICA: LIST OF REGULATORY BODIES, GOVERNMENT AGENCIES, INDUSTRY ASSOCIATIONS, AND OTHER ORGANIZATIONS

- TABLE 3 EUROPE: LIST OF REGULATORY BODIES, GOVERNMENT AGENCIES, INDUSTRY ASSOCIATIONS, AND OTHER ORGANIZATIONS

- TABLE 4 ASIA PACIFIC: LIST OF REGULATORY BODIES, GOVERNMENT AGENCIES, INDUSTRY ASSOCIATIONS, AND OTHER ORGANIZATIONS

- TABLE 5 MIDDLE EAST & AFRICA: LIST OF REGULATORY BODIES, GOVERNMENT AGENCIES, INDUSTRY ASSOCIATIONS, AND OTHER ORGANIZATIONS

- TABLE 6 SOUTH AMERICA: LIST OF REGULATORY BODIES, GOVERNMENT AGENCIES, INDUSTRY ASSOCIATIONS, AND OTHER ORGANIZATIONS

- TABLE 7 INDICATIVE PRICING ANALYSIS OF METALIZED FLEXIBLE PACKAGING, BY END-USE INDUSTRY, 2024 (USD/KG)

- TABLE 8 AVERAGE SELLING PRICE TREND OF METALIZED FLEXIBLE PACKAGING, BY REGION, 2021-2030 (USD/KG)

- TABLE 9 EXPORT DATA FOR HS CODE 7607-COMPLIANT PRODUCTS, BY COUNTRY, 2020-2024 (USD MILLION)

- TABLE 10 IMPORT DATA FOR HS CODE 7607-COMPLIANT PRODUCTS, BY COUNTRY, 2020-2024 (USD MILLION)

- TABLE 11 LIST OF KEY PATENTS, 2022-2024

- TABLE 12 INFLUENCE OF STAKEHOLDERS ON BUYING PROCESS, BY END-USE INDUSTRY

- TABLE 13 BUYING CRITERIA FOR KEY END-USE INDUSTRIES

- TABLE 14 LIST OF CONFERENCES AND EVENTS, 2025-2026

- TABLE 15 METALIZED FLEXIBLE PACKAGING MARKET: PORTER'S FIVE FORCES ANALYSIS

- TABLE 16 GLOBAL GDP GROWTH PROJECTIONS, BY REGION, 2021-2028 (USD TRILLION)

- TABLE 17 KEY TARIFF RATES IMPOSED ON VARIOUS COUNTRIES AS PER RECENT RECIPROCAL TARIFFS ANNOUNCED BY US ADMINISTRATION, 2025

- TABLE 18 METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (USD MILLION)

- TABLE 19 METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (USD MILLION)

- TABLE 20 METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (KILOTON)

- TABLE 21 METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (KILOTON)

- TABLE 22 METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (USD MILLION)

- TABLE 23 METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (USD MILLION)

- TABLE 24 METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (KILOTON)

- TABLE 25 METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (KILOTON)

- TABLE 26 METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (USD MILLION)

- TABLE 27 METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (USD MILLION)

- TABLE 28 METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (KILOTON)

- TABLE 29 METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (KILOTON)

- TABLE 30 METALIZED FLEXIBLE PACKAGING MARKET, BY STRUCTURE, 2021-2023 (USD MILLION)

- TABLE 31 METALIZED FLEXIBLE PACKAGING MARKET, BY STRUCTURE, 2024-2030 (USD MILLION)

- TABLE 32 METALIZED FLEXIBLE PACKAGING MARKET, BY STRUCTURE, 2021-2023 (KILOTON)

- TABLE 33 METALIZED FLEXIBLE PACKAGING MARKET, BY STRUCTURE, 2024-2030 (KILOTON)

- TABLE 34 METALIZED FLEXIBLE PACKAGING MARKET, BY REGION, 2021-2023 (USD MILLION)

- TABLE 35 METALIZED FLEXIBLE PACKAGING MARKET, BY REGION, 2024-2030 (USD MILLION)

- TABLE 36 METALIZED FLEXIBLE PACKAGING MARKET, BY REGION, 2021-2023 (KILOTON)

- TABLE 37 METALIZED FLEXIBLE PACKAGING MARKET, BY REGION, 2024-2030 (KILOTON)

- TABLE 38 ASIA PACIFIC: METALIZED FLEXIBLE PACKAGING MARKET, BY COUNTRY, 2021-2023 (USD MILLION)

- TABLE 39 ASIA PACIFIC: METALIZED FLEXIBLE PACKAGING MARKET, BY COUNTRY, 2024-2030 (USD MILLION)

- TABLE 40 ASIA PACIFIC: METALIZED FLEXIBLE PACKAGING MARKET, BY COUNTRY, 2021-2023 (KILOTON)

- TABLE 41 ASIA PACIFIC: METALIZED FLEXIBLE PACKAGING MARKET, BY COUNTRY, 2024-2030 (KILOTON)

- TABLE 42 ASIA PACIFIC: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (USD MILLION)

- TABLE 43 ASIA PACIFIC: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (USD MILLION)

- TABLE 44 ASIA PACIFIC: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (KILOTON)

- TABLE 45 ASIA PACIFIC: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (KILOTON)

- TABLE 46 ASIA PACIFIC: METALIZED FLEXIBLE PACKAGING MARKET, BY STRUCTURE, 2021-2023 (USD MILLION)

- TABLE 47 ASIA PACIFIC: METALIZED FLEXIBLE PACKAGING MARKET, BY STRUCTURE, 2024-2030 (USD MILLION)

- TABLE 48 ASIA PACIFIC: METALIZED FLEXIBLE PACKAGING MARKET, BY STRUCTURE, 2021-2023 (KILOTON)

- TABLE 49 ASIA PACIFIC: METALIZED FLEXIBLE PACKAGING MARKET, BY STRUCTURE, 2024-2030 (KILOTON)

- TABLE 50 ASIA PACIFIC: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (USD MILLION)

- TABLE 51 ASIA PACIFIC: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (USD MILLION)

- TABLE 52 ASIA PACIFIC: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (KILOTON)

- TABLE 53 ASIA PACIFIC: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (KILOTON)

- TABLE 54 ASIA PACIFIC: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (USD MILLION)

- TABLE 55 ASIA PACIFIC: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (USD MILLION)

- TABLE 56 ASIA PACIFIC: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (KILOTON)

- TABLE 57 ASIA PACIFIC: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (KILOTON)

- TABLE 58 CHINA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (USD MILLION)

- TABLE 59 CHINA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (USD MILLION)

- TABLE 60 CHINA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (KILOTON)

- TABLE 61 CHINA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (KILOTON)

- TABLE 62 CHINA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (USD MILLION)

- TABLE 63 CHINA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (USD MILLION)

- TABLE 64 CHINA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (KILOTON)

- TABLE 65 CHINA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (KILOTON)

- TABLE 66 CHINA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (USD MILLION)

- TABLE 67 CHINA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (USD MILLION)

- TABLE 68 CHINA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (KILOTON)

- TABLE 69 CHINA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (KILOTON)

- TABLE 70 INDIA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (USD MILLION)

- TABLE 71 INDIA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (USD MILLION)

- TABLE 72 INDIA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (KILOTON)

- TABLE 73 INDIA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (KILOTON)

- TABLE 74 INDIA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (USD MILLION)

- TABLE 75 INDIA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (USD MILLION)

- TABLE 76 INDIA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (KILOTON)

- TABLE 77 INDIA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (KILOTON)

- TABLE 78 INDIA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (USD MILLION)

- TABLE 79 INDIA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (USD MILLION)

- TABLE 80 INDIA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (KILOTON)

- TABLE 81 INDIA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (KILOTON)

- TABLE 82 JAPAN: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (USD MILLION)

- TABLE 83 JAPAN: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (USD MILLION)

- TABLE 84 JAPAN: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (KILOTON)

- TABLE 85 JAPAN: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (KILOTON)

- TABLE 86 JAPAN: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (USD MILLION)

- TABLE 87 JAPAN: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (USD MILLION)

- TABLE 88 JAPAN: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (KILOTON)

- TABLE 89 JAPAN: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (KILOTON)

- TABLE 90 JAPAN: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (USD MILLION)

- TABLE 91 JAPAN: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (USD MILLION)

- TABLE 92 JAPAN: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (KILOTON)

- TABLE 93 JAPAN: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (KILOTON)

- TABLE 94 SOUTH KOREA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (USD MILLION)

- TABLE 95 SOUTH KOREA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (USD MILLION)

- TABLE 96 SOUTH KOREA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (KILOTON)

- TABLE 97 SOUTH KOREA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (KILOTON)

- TABLE 98 SOUTH KOREA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (USD MILLION)

- TABLE 99 SOUTH KOREA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (USD MILLION)

- TABLE 100 SOUTH KOREA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (KILOTON)

- TABLE 101 SOUTH KOREA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (KILOTON)

- TABLE 102 SOUTH KOREA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (USD MILLION)

- TABLE 103 SOUTH KOREA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (USD MILLION)

- TABLE 104 SOUTH KOREA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (KILOTON)

- TABLE 105 SOUTH KOREA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (KILOTON)

- TABLE 106 REST OF ASIA PACIFIC: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (USD MILLION)

- TABLE 107 REST OF ASIA PACIFIC: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (USD MILLION)

- TABLE 108 REST OF ASIA PACIFIC: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (KILOTON)

- TABLE 109 REST OF ASIA PACIFIC: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (KILOTON)

- TABLE 110 REST OF ASIA PACIFIC: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (USD MILLION)

- TABLE 111 REST OF ASIA PACIFIC: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (USD MILLION)

- TABLE 112 REST OF ASIA PACIFIC: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (KILOTON)

- TABLE 113 REST OF ASIA PACIFIC: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (KILOTON)

- TABLE 114 REST OF ASIA PACIFIC: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (USD MILLION)

- TABLE 115 REST OF ASIA PACIFIC: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (USD MILLION)

- TABLE 116 REST OF ASIA PACIFIC: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (KILOTON)

- TABLE 117 REST OF ASIA PACIFIC: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (KILOTON)

- TABLE 118 EUROPE: METALIZED FLEXIBLE PACKAGING MARKET, BY COUNTRY, 2021-2023 (USD MILLION)

- TABLE 119 EUROPE: METALIZED FLEXIBLE PACKAGING MARKET, BY COUNTRY, 2024-2030 (USD MILLION)

- TABLE 120 EUROPE: METALIZED FLEXIBLE PACKAGING MARKET, BY COUNTRY, 2021-2023 (KILOTON)

- TABLE 121 EUROPE: METALIZED FLEXIBLE PACKAGING MARKET, BY COUNTRY, 2024-2030 (KILOTON)

- TABLE 122 EUROPE: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (USD MILLION)

- TABLE 123 EUROPE: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (USD MILLION)

- TABLE 124 EUROPE: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (KILOTON)

- TABLE 125 EUROPE: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (KILOTON)

- TABLE 126 EUROPE: METALIZED FLEXIBLE PACKAGING MARKET, BY STRUCTURE, 2021-2023 (USD MILLION)

- TABLE 127 EUROPE: METALIZED FLEXIBLE PACKAGING MARKET, BY STRUCTURE, 2024-2030 (USD MILLION)

- TABLE 128 EUROPE: METALIZED FLEXIBLE PACKAGING MARKET, BY STRUCTURE, 2021-2023 (KILOTON)

- TABLE 129 EUROPE: METALIZED FLEXIBLE PACKAGING MARKET, BY STRUCTURE, 2024-2030 (KILOTON)

- TABLE 130 EUROPE: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (USD MILLION)

- TABLE 131 EUROPE: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (USD MILLION)

- TABLE 132 EUROPE: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (KILOTON)

- TABLE 133 EUROPE: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (KILOTON)

- TABLE 134 EUROPE: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (USD MILLION)

- TABLE 135 EUROPE: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (USD MILLION)

- TABLE 136 EUROPE: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (KILOTON)

- TABLE 137 EUROPE: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (KILOTON)

- TABLE 138 GERMANY: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (USD MILLION)

- TABLE 139 GERMANY: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (USD MILLION)

- TABLE 140 GERMANY: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (KILOTON)

- TABLE 141 GERMANY: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (KILOTON)

- TABLE 142 GERMANY: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (USD MILLION)

- TABLE 143 GERMANY: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (USD MILLION)

- TABLE 144 GERMANY: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (KILOTON)

- TABLE 145 GERMANY: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (KILOTON)

- TABLE 146 GERMANY: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (USD MILLION)

- TABLE 147 GERMANY: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (USD MILLION)

- TABLE 148 GERMANY: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (KILOTON)

- TABLE 149 GERMANY: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (KILOTON)

- TABLE 150 UK: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (USD MILLION)

- TABLE 151 UK: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (USD MILLION)

- TABLE 152 UK: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (KILOTON)

- TABLE 153 UK: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (KILOTON)

- TABLE 154 UK: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (USD MILLION)

- TABLE 155 UK: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (USD MILLION)

- TABLE 156 UK: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (KILOTON)

- TABLE 157 UK: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (KILOTON)

- TABLE 158 UK: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (USD MILLION)

- TABLE 159 UK: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (USD MILLION)

- TABLE 160 UK: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (KILOTON)

- TABLE 161 UK: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (KILOTON)

- TABLE 162 FRANCE: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (USD MILLION)

- TABLE 163 FRANCE: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (USD MILLION)

- TABLE 164 FRANCE: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (KILOTON)

- TABLE 165 FRANCE: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (KILOTON)

- TABLE 166 FRANCE: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (USD MILLION)

- TABLE 167 FRANCE: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (USD MILLION)

- TABLE 168 FRANCE: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (KILOTON)

- TABLE 169 FRANCE: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (KILOTON)

- TABLE 170 FRANCE: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (USD MILLION)

- TABLE 171 FRANCE: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (USD MILLION)

- TABLE 172 FRANCE: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (KILOTON)

- TABLE 173 FRANCE: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (KILOTON)

- TABLE 174 ITALY: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (USD MILLION)

- TABLE 175 ITALY: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (USD MILLION)

- TABLE 176 ITALY: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (KILOTON)

- TABLE 177 ITALY: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (KILOTON)

- TABLE 178 ITALY: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (USD MILLION)

- TABLE 179 ITALY: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (USD MILLION)

- TABLE 180 ITALY: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (KILOTON)

- TABLE 181 ITALY: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (KILOTON)

- TABLE 182 ITALY: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (USD MILLION)

- TABLE 183 ITALY: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (USD MILLION)

- TABLE 184 ITALY: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (KILOTON)

- TABLE 185 ITALY: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (KILOTON)

- TABLE 186 SPAIN: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (USD MILLION)

- TABLE 187 SPAIN: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (USD MILLION)

- TABLE 188 SPAIN: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (KILOTON)

- TABLE 189 SPAIN: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (KILOTON)

- TABLE 190 SPAIN: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (USD MILLION)

- TABLE 191 SPAIN: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (USD MILLION)

- TABLE 192 SPAIN: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (KILOTON)

- TABLE 193 SPAIN: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (KILOTON)

- TABLE 194 SPAIN: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (USD MILLION)

- TABLE 195 SPAIN: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (USD MILLION)

- TABLE 196 SPAIN: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (KILOTON)

- TABLE 197 SPAIN: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (KILOTON)

- TABLE 198 RUSSIA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (USD MILLION)

- TABLE 199 RUSSIA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (USD MILLION)

- TABLE 200 RUSSIA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (KILOTON)

- TABLE 201 RUSSIA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (KILOTON)

- TABLE 202 RUSSIA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (USD MILLION)

- TABLE 203 RUSSIA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (USD MILLION)

- TABLE 204 RUSSIA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (KILOTON)

- TABLE 205 RUSSIA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (KILOTON)

- TABLE 206 RUSSIA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (USD MILLION)

- TABLE 207 RUSSIA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (USD MILLION)

- TABLE 208 RUSSIA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (KILOTON)

- TABLE 209 RUSSIA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (KILOTON)

- TABLE 210 REST OF EUROPE: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (USD MILLION)

- TABLE 211 REST OF EUROPE: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (USD MILLION)

- TABLE 212 REST OF EUROPE: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (KILOTON)

- TABLE 213 REST OF EUROPE: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (KILOTON)

- TABLE 214 REST OF EUROPE: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (USD MILLION)

- TABLE 215 REST OF EUROPE: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (USD MILLION)

- TABLE 216 REST OF EUROPE: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (KILOTON)

- TABLE 217 REST OF EUROPE: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (KILOTON)

- TABLE 218 REST OF EUROPE: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (USD MILLION)

- TABLE 219 REST OF EUROPE: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (USD MILLION)

- TABLE 220 REST OF EUROPE: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (KILOTON)

- TABLE 221 REST OF EUROPE: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (KILOTON)

- TABLE 222 NORTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY COUNTRY, 2021-2023 (USD MILLION)

- TABLE 223 NORTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY COUNTRY, 2024-2030 (USD MILLION)

- TABLE 224 NORTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY COUNTRY, 2021-2023 (KILOTON)

- TABLE 225 NORTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY COUNTRY, 2024-2030 (KILOTON)

- TABLE 226 NORTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (USD MILLION)

- TABLE 227 NORTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (USD MILLION)

- TABLE 228 NORTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (KILOTON)

- TABLE 229 NORTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (KILOTON)

- TABLE 230 NORTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY STRUCTURE, 2021-2023 (USD MILLION)

- TABLE 231 NORTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY STRUCTURE, 2024-2030 (USD MILLION)

- TABLE 232 NORTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY STRUCTURE, 2021-2023 (KILOTON)

- TABLE 233 NORTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY STRUCTURE, 2024-2030 (KILOTON)

- TABLE 234 NORTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (USD MILLION)

- TABLE 235 NORTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (USD MILLION)

- TABLE 236 NORTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (KILOTON)

- TABLE 237 NORTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (KILOTON)

- TABLE 238 NORTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (USD MILLION)

- TABLE 239 NORTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (USD MILLION)

- TABLE 240 NORTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (KILOTON)

- TABLE 241 NORTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (KILOTON)

- TABLE 242 US: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (USD MILLION)

- TABLE 243 US: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (USD MILLION)

- TABLE 244 US: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (KILOTON)

- TABLE 245 US: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (KILOTON)

- TABLE 246 US: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (USD MILLION)

- TABLE 247 US: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (USD MILLION)

- TABLE 248 US: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (KILOTON)

- TABLE 249 US: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (KILOTON)

- TABLE 250 US: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (USD MILLION)

- TABLE 251 US: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (USD MILLION)

- TABLE 252 US: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (KILOTON)

- TABLE 253 US: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (KILOTON)

- TABLE 254 CANADA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (USD MILLION)

- TABLE 255 CANADA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (USD MILLION)

- TABLE 256 CANADA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (KILOTON)

- TABLE 257 CANADA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (KILOTON)

- TABLE 258 CANADA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (USD MILLION)

- TABLE 259 CANADA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (USD MILLION)

- TABLE 260 CANADA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (KILOTON)

- TABLE 261 CANADA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (KILOTON)

- TABLE 262 CANADA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (USD MILLION)

- TABLE 263 CANADA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (USD MILLION)

- TABLE 264 CANADA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (KILOTON)

- TABLE 265 CANADA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (KILOTON)

- TABLE 266 MEXICO: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (USD MILLION)

- TABLE 267 MEXICO: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (USD MILLION)

- TABLE 268 MEXICO: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (KILOTON)

- TABLE 269 MEXICO: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (KILOTON)

- TABLE 270 MEXICO: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (USD MILLION)

- TABLE 271 MEXICO: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (USD MILLION)

- TABLE 272 MEXICO: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (KILOTON)

- TABLE 273 MEXICO: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (KILOTON)

- TABLE 274 MEXICO: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (USD MILLION)

- TABLE 275 MEXICO: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (USD MILLION)

- TABLE 276 MEXICO: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (KILOTON)

- TABLE 277 MEXICO: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (KILOTON)

- TABLE 278 SOUTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY COUNTRY, 2021-2023 (USD MILLION)

- TABLE 279 SOUTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY COUNTRY, 2024-2030 (USD MILLION)

- TABLE 280 SOUTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY COUNTRY, 2021-2023 (KILOTON)

- TABLE 281 SOUTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY COUNTRY, 2024-2030 (KILOTON)

- TABLE 282 SOUTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (USD MILLION)

- TABLE 283 SOUTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (USD MILLION)

- TABLE 284 SOUTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (KILOTON)

- TABLE 285 SOUTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (KILOTON)

- TABLE 286 SOUTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY STRUCTURE, 2021-2023 (USD MILLION)

- TABLE 287 SOUTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY STRUCTURE, 2024-2030 (USD MILLION)

- TABLE 288 SOUTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY STRUCTURE, 2021-2023 (KILOTON)

- TABLE 289 SOUTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY STRUCTURE, 2024-2030 (KILOTON)

- TABLE 290 SOUTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (USD MILLION)

- TABLE 291 SOUTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (USD MILLION)

- TABLE 292 SOUTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (KILOTON)

- TABLE 293 SOUTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (KILOTON)

- TABLE 294 SOUTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (USD MILLION)

- TABLE 295 SOUTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (USD MILLION)

- TABLE 296 SOUTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (KILOTON)

- TABLE 297 SOUTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (KILOTON)

- TABLE 298 BRAZIL: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (USD MILLION)

- TABLE 299 BRAZIL: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (USD MILLION)

- TABLE 300 BRAZIL: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (KILOTON)

- TABLE 301 BRAZIL: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (KILOTON)

- TABLE 302 BRAZIL: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (USD MILLION)

- TABLE 303 BRAZIL: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (USD MILLION)

- TABLE 304 BRAZIL: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (KILOTON)

- TABLE 305 BRAZIL: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (KILOTON)

- TABLE 306 BRAZIL: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (USD MILLION)

- TABLE 307 BRAZIL: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (USD MILLION)

- TABLE 308 BRAZIL: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (KILOTON)

- TABLE 309 BRAZIL: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (KILOTON)

- TABLE 310 ARGENTINA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (USD MILLION)

- TABLE 311 ARGENTINA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (USD MILLION)

- TABLE 312 ARGENTINA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (KILOTON)

- TABLE 313 ARGENTINA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (KILOTON)

- TABLE 314 ARGENTINA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (USD MILLION)

- TABLE 315 ARGENTINA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (USD MILLION)

- TABLE 316 ARGENTINA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (KILOTON)

- TABLE 317 ARGENTINA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (KILOTON)

- TABLE 318 ARGENTINA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (USD MILLION)

- TABLE 319 ARGENTINA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (USD MILLION)

- TABLE 320 ARGENTINA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (KILOTON)

- TABLE 321 ARGENTINA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (KILOTON)

- TABLE 322 REST OF SOUTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (USD MILLION)

- TABLE 323 REST OF SOUTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (USD MILLION)

- TABLE 324 REST OF SOUTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (KILOTON)

- TABLE 325 REST OF SOUTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (KILOTON)

- TABLE 326 REST OF SOUTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (USD MILLION)

- TABLE 327 REST OF SOUTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (USD MILLION)

- TABLE 328 REST OF SOUTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (KILOTON)

- TABLE 329 REST OF SOUTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (KILOTON)

- TABLE 330 REST OF SOUTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (USD MILLION)

- TABLE 331 REST OF SOUTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (USD MILLION)

- TABLE 332 REST OF SOUTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (KILOTON)

- TABLE 333 REST OF SOUTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (KILOTON)

- TABLE 334 MIDDLE EAST & AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY COUNTRY, 2021-2023 (USD MILLION)

- TABLE 335 MIDDLE EAST & AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY COUNTRY, 2024-2030 (USD MILLION)

- TABLE 336 MIDDLE EAST & AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY COUNTRY, 2021-2023 (KILOTON)

- TABLE 337 MIDDLE EAST & AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY COUNTRY, 2024-2030 (KILOTON)

- TABLE 338 MIDDLE EAST & AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (USD MILLION)

- TABLE 339 MIDDLE EAST & AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (USD MILLION)

- TABLE 340 MIDDLE EAST & AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (KILOTON)

- TABLE 341 MIDDLE EAST & AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (KILOTON)

- TABLE 342 MIDDLE EAST & AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY STRUCTURE, 2021-2023 (USD MILLION)

- TABLE 343 MIDDLE EAST & AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY STRUCTURE, 2024-2030 (USD MILLION)

- TABLE 344 MIDDLE EAST & AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY STRUCTURE, 2021-2023 (KILOTON)

- TABLE 345 MIDDLE EAST & AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY STRUCTURE, 2024-2030 (KILOTON)

- TABLE 346 MIDDLE EAST & AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (USD MILLION)

- TABLE 347 MIDDLE EAST & AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (USD MILLION)

- TABLE 348 MIDDLE EAST & AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (KILOTON)

- TABLE 349 MIDDLE EAST & AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (KILOTON)

- TABLE 350 MIDDLE EAST & AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (USD MILLION)

- TABLE 351 MIDDLE EAST & AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (USD MILLION)

- TABLE 352 MIDDLE EAST & AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (KILOTON)

- TABLE 353 MIDDLE EAST & AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (KILOTON)

- TABLE 354 GCC COUNTRIES: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (USD MILLION)

- TABLE 355 GCC COUNTRIES: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (USD MILLION)

- TABLE 356 GCC COUNTRIES: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (KILOTON)

- TABLE 357 GCC COUNTRIES: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (KILOTON)

- TABLE 358 GCC COUNTRIES: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (USD MILLION)

- TABLE 359 GCC COUNTRIES: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (USD MILLION)

- TABLE 360 GCC COUNTRIES: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (KILOTON)

- TABLE 361 GCC COUNTRIES: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (KILOTON)

- TABLE 362 GCC COUNTRIES: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (USD MILLION)

- TABLE 363 GCC COUNTRIES: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (USD MILLION)

- TABLE 364 GCC COUNTRIES: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (KILOTON)

- TABLE 365 GCC COUNTRIES: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (KILOTON)

- TABLE 366 UAE: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (USD MILLION)

- TABLE 367 UAE: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (USD MILLION)

- TABLE 368 UAE: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (KILOTON)

- TABLE 369 UAE: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (KILOTON)

- TABLE 370 UAE: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (USD MILLION)

- TABLE 371 UAE: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (USD MILLION)

- TABLE 372 UAE: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (KILOTON)

- TABLE 373 UAE: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (KILOTON)

- TABLE 374 UAE: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (USD MILLION)

- TABLE 375 UAE: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (USD MILLION)

- TABLE 376 UAE: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (KILOTON)

- TABLE 377 UAE: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (KILOTON)

- TABLE 378 SAUDI ARABIA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (USD MILLION)

- TABLE 379 SAUDI ARABIA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (USD MILLION)

- TABLE 380 SAUDI ARABIA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (KILOTON)

- TABLE 381 SAUDI ARABIA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (KILOTON)

- TABLE 382 SAUDI ARABIA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (USD MILLION)

- TABLE 383 SAUDI ARABIA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (USD MILLION)

- TABLE 384 SAUDI ARABIA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (KILOTON)

- TABLE 385 SAUDI ARABIA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (KILOTON)

- TABLE 386 SAUDI ARABIA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (USD MILLION)

- TABLE 387 SAUDI ARABIA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (USD MILLION)

- TABLE 388 SAUDI ARABIA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (KILOTON)

- TABLE 389 SAUDI ARABIA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (KILOTON)

- TABLE 390 REST OF GCC COUNTRIES: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (USD MILLION)

- TABLE 391 REST OF GCC COUNTRIES: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (USD MILLION)

- TABLE 392 REST OF GCC COUNTRIES: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (KILOTON)

- TABLE 393 REST OF GCC COUNTRIES: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (KILOTON)

- TABLE 394 REST OF GCC COUNTRIES: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (USD MILLION)

- TABLE 395 REST OF GCC COUNTRIES: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (USD MILLION)

- TABLE 396 REST OF GCC COUNTRIES: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (KILOTON)

- TABLE 397 REST OF GCC COUNTRIES: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (KILOTON)

- TABLE 398 REST OF GCC COUNTRIES: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (USD MILLION)

- TABLE 399 REST OF GCC COUNTRIES: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (USD MILLION)

- TABLE 400 REST OF GCC COUNTRIES: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (KILOTON)

- TABLE 401 REST OF GCC COUNTRIES: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (KILOTON)

- TABLE 402 SOUTH AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (USD MILLION)

- TABLE 403 SOUTH AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (USD MILLION)

- TABLE 404 SOUTH AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (KILOTON)

- TABLE 405 SOUTH AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (KILOTON)

- TABLE 406 SOUTH AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (USD MILLION)

- TABLE 407 SOUTH AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (USD MILLION)

- TABLE 408 SOUTH AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (KILOTON)

- TABLE 409 SOUTH AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (KILOTON)

- TABLE 410 SOUTH AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (USD MILLION)

- TABLE 411 SOUTH AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (USD MILLION)

- TABLE 412 SOUTH AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (KILOTON)

- TABLE 413 SOUTH AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (KILOTON)

- TABLE 414 REST OF MIDDLE EAST & AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (USD MILLION)

- TABLE 415 REST OF MIDDLE EAST & AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (USD MILLION)

- TABLE 416 REST OF MIDDLE EAST & AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2021-2023 (KILOTON)

- TABLE 417 REST OF MIDDLE EAST & AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY MATERIAL TYPE, 2024-2030 (KILOTON)

- TABLE 418 REST OF MIDDLE EAST & AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (USD MILLION)

- TABLE 419 REST OF MIDDLE EAST & AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (USD MILLION)

- TABLE 420 REST OF MIDDLE EAST & AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2021-2023 (KILOTON)

- TABLE 421 REST OF MIDDLE EAST & AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2024-2030 (KILOTON)

- TABLE 422 REST OF MIDDLE EAST & AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (USD MILLION)

- TABLE 423 REST OF MIDDLE EAST & AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (USD MILLION)

- TABLE 424 REST OF MIDDLE EAST & AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2021-2023 (KILOTON)

- TABLE 425 REST OF MIDDLE EAST & AFRICA: METALIZED FLEXIBLE PACKAGING MARKET, BY END-USE INDUSTRY, 2024-2030 (KILOTON)

- TABLE 426 METALIZED FLEXIBLE PACKAGING MARKET: OVERVIEW OF STRATEGIES ADOPTED BY MARKET PLAYERS BETWEEN JANUARY 2020 AND JUNE 2025

- TABLE 427 METALIZED FLEXIBLE PACKAGING MARKET: DEGREE OF COMPETITION

- TABLE 428 METALIZED FLEXIBLE PACKAGING MARKET: REGION FOOTPRINT

- TABLE 429 METALIZED FLEXIBLE PACKAGING MARKET: STRUCTURE FOOTPRINT

- TABLE 430 METALIZED FLEXIBLE PACKAGING MARKET: PACKAGING TYPE FOOTPRINT

- TABLE 431 METALIZED FLEXIBLE PACKAGING MARKET: END-USE INDUSTRY FOOTPRINT

- TABLE 432 METALIZED FLEXIBLE PACKAGING MARKET: DETAILED LIST OF KEY STARTUPS/SMES

- TABLE 433 METALIZED FLEXIBLE PACKAGING MARKET: COMPETITIVE BENCHMARKING OF KEY STARTUPS/SMES

- TABLE 434 METALIZED FLEXIBLE PACKAGING MARKET: PRODUCT LAUNCHES, JANUARY 2020-JUNE 2025

- TABLE 435 METALIZED FLEXIBLE PACKAGING MARKET: DEALS, JANUARY 2020-JUNE 2025

- TABLE 436 METALIZED FLEXIBLE PACKAGING MARKET: EXPANSIONS, JANUARY 2020-JUNE 2025

- TABLE 437 AMCOR PLC: COMPANY OVERVIEW

- TABLE 438 AMCOR PLC: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 439 AMCOR PLC: PRODUCT LAUNCHES, JANUARY 2020-JUNE 2025

- TABLE 440 AMCOR PLC: DEALS, JANUARY 2020-JUNE 2025

- TABLE 441 AMCOR PLC: EXPANSIONS, JANUARY 2020-JUNE 2025

- TABLE 442 MONDI: COMPANY OVERVIEW

- TABLE 443 MONDI: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 444 MONDI: DEALS, JANUARY 2020-JUNE 2025

- TABLE 445 MONDI: EXPANSIONS, JANUARY 2020-JUNE 2025

- TABLE 446 SEALED AIR CORPORATION: COMPANY OVERVIEW

- TABLE 447 SEALED AIR CORPORATION: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 448 SEALED AIR CORPORATION: DEALS, JANUARY 2020-JUNE 2025

- TABLE 449 HUHTAMAKI OYJ: COMPANY OVERVIEW

- TABLE 450 HUHTAMAKI OYJ: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 451 HUHTAMAKI OYJ: DEALS, JANUARY 2020-JUNE 2025

- TABLE 452 TOPPAN HOLDINGS INC.: COMPANY OVERVIEW

- TABLE 453 TOPPAN HOLDINGS INC.: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 454 TOPPAN HOLDINGS INC.: DEALS, JANUARY 2020-JUNE 2025

- TABLE 455 TRANSCONTINENTAL INC.: COMPANY OVERVIEW

- TABLE 456 TRANSCONTINENTAL INC.: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 457 TRANSCONTINENTAL INC.: PRODUCT LAUNCHES, JANUARY 2020-JUNE 2025

- TABLE 458 TRANSCONTINENTAL INC: DEALS, JANUARY 2020-JUNE 2025

- TABLE 459 TRANSCONTINENTAL INC: EXPANSIONS, JANUARY 2020-JUNE 2025

- TABLE 460 POLPLEX CORPORATION LIMITED: COMPANY OVERVIEW

- TABLE 461 POLPLEX CORPORATION LIMITED: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 462 COSMO FIRST LIMITED: COMPANY OVERVIEW

- TABLE 463 COSMO FIRST LIMITED: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 464 COSMO FIRST LIMITED: DEALS

- TABLE 465 UFLEX LIMITED: COMPANY OVERVIEW

- TABLE 466 UFLEX LIMITED: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 467 UFLEX LIMITED: PRODUCT LAUNCHES, JANUARY 2020-JUNE 2025

- TABLE 468 JPFL FILMS PRIVATE LIMITED: COMPANY OVERVIEW

- TABLE 469 JPFL FILMS PRIVATE LIMITED: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 470 JPFL FILMS PRIVATE LIMITED: DEALS

- TABLE 471 ESTER INDUSTRIES LIMITED: COMPANY OVERVIEW

- TABLE 472 CONSTANTIA FLEXIBLES: COMPANY OVERVIEW

- TABLE 473 TAGHLEEF INDUSTRIES: COMPANY OVERVIEW

- TABLE 474 POLINAS: COMPANY OVERVIEW

- TABLE 475 DUNMORE: COMPANY OVERVIEW

- TABLE 476 GR (SHANDONG) NEW MATERIAL CO.,LTD.: COMPANY OVERVIEW

- TABLE 477 SHANGHAI RUITU NEW MATERIALS TECHNOLOGY CO., LTD.: COMPANY OVERVIEW

- TABLE 478 XIAMEN CHANGSU INDUSTRIAL CO., LTD.: COMPANY OVERVIEW

- TABLE 479 CELPLAST METALLIZED PRODUCTS LIMITED: COMPANY OVERVIEW

- TABLE 480 ULTIMET FILMS LIMITED: COMPANY OVERVIEW

- TABLE 481 ACCRUED PLASTIC LTD.: COMPANY OVERVIEW

- TABLE 482 ALL FOILS, INC.: COMPANY OVERVIEW

- TABLE 483 MANUCOR SPA: COMPANY OVERVIEW

- TABLE 484 SRF LIMITED: COMPANY OVERVIEW

- TABLE 485 KAVERI METALLISING & COATING IND. PRIVATE LIMITED: COMPANY OVERVIEW

- TABLE 486 FLEXIBLE PACKAGING MARKET, BY MATERIAL, 2020-2022 (USD MILLION)

- TABLE 487 FLEXIBLE PACKAGING MARKET, BY MATERIAL, 2023-2029 (USD MILLION)

- TABLE 488 FLEXIBLE PACKAGING MARKET, BY MATERIAL, 2020-2022 (KILOTON)

- TABLE 489 FLEXIBLE PACKAGING MARKET, BY MATERIAL, 2023-2029 (KILOTON)

- TABLE 490 FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2020-2022 (USD MILLION)

- TABLE 491 FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2023-2029 (USD MILLION)

- TABLE 492 FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2020-2022 (KILOTON)

- TABLE 493 FLEXIBLE PACKAGING MARKET, BY PACKAGING TYPE, 2023-2029 (KILOTON)

- TABLE 494 FLEXIBLE PACKAGING MARKET, BY PRINTING TECHNOLOGY, 2020-2022 (USD MILLION)

- TABLE 495 FLEXIBLE PACKAGING MARKET, BY PRINTING TECHNOLOGY, 2023-2029 (USD MILLION)

- TABLE 496 FLEXIBLE PACKAGING MARKET, BY PRINTING TECHNOLOGY, 2020-2022 (KILOTON)

- TABLE 497 FLEXIBLE PACKAGING MARKET, BY PRINTING TECHNOLOGY, 2023-2029 (KILOTON)

- TABLE 498 FLEXIBLE PACKAGING MARKET, BY APPLICATION, 2020-2022 (USD MILLION)

- TABLE 499 FLEXIBLE PACKAGING MARKET, BY APPLICATION, 2023-2029 (USD MILLION)

- TABLE 500 FLEXIBLE PACKAGING MARKET, BY APPLICATION, 2020-2022 (KILOTON)

- TABLE 501 FLEXIBLE PACKAGING MARKET, BY APPLICATION, 2023-2029 (KILOTON)

- TABLE 502 FLEXIBLE PACKAGING MARKET, BY REGION, 2020-2022 (USD MILLION)

- TABLE 503 FLEXIBLE PACKAGING MARKET, BY REGION, 2023-2029 (USD MILLION)

- TABLE 504 FLEXIBLE PACKAGING MARKET, BY REGION, 2020-2022 (KILOTON)

- TABLE 505 FLEXIBLE PACKAGING MARKET, BY REGION, 2023-2029 (KILOTON)

List of Figures

- FIGURE 1 METALIZED FLEXIBLE PACKAGING MARKET SEGMENTATION AND REGIONAL SCOPE

- FIGURE 2 METALIZED FLEXIBLE PACKAGING MARKET: RESEARCH DESIGN

- FIGURE 3 MARKET SIZE ESTIMATION: SUPPLY SIDE APPROACH-1

- FIGURE 4 MARKET SIZE ESTIMATION: SUPPLY SIDE APPROACH-2

- FIGURE 5 MARKET SIZE ESTIMATION: SUPPLY SIDE APPROACH-3

- FIGURE 6 METALIZED FLEXIBLE PACKAGING MARKET: DATA TRIANGULATION

- FIGURE 7 ALUMINUM-FOIL-BASED FLEXIBLE PACKAGING TO BE LARGEST MATERIAL TYPE SEGMENT DURING FORECAST PERIOD

- FIGURE 8 LAMINATED STRUCTURES TO BE LARGEST SEGMENT DURING FORECAST PERIOD

- FIGURE 9 POUCHES TO BE FASTEST-GROWING APPLICATION DURING FORECAST PERIOD

- FIGURE 10 FOOD TO BE LARGEST END-USE INDUSTRY SEGMENT DURING FORECAST PERIOD

- FIGURE 11 ASIA PACIFIC LED METALIZED FLEXIBLE PACKAGING MARKET IN 2024

- FIGURE 12 ASIA PACIFIC TO BE FASTEST-GROWING REGION IN METALIZED FLEXIBLE PACKAGING MARKET DURING FORECAST PERIOD

- FIGURE 13 ALUMINUM-FOIL-BASED FLEXIBLE PACKAGING SEGMENT TO LEAD MARKET DURING FORECAST PERIOD

- FIGURE 14 LAMINATED STRUCTURES SEGMENT TO LEAD MARKET DURING FORECAST PERIOD

- FIGURE 15 POUCHES SEGMENT TO LEAD MARKET DURING FORECAST PERIOD

- FIGURE 16 FOOD TO BE LARGEST END-USE INDUSTRY SEGMENT DURING FORECAST PERIOD

- FIGURE 17 CHINA ACCOUNTED FOR LARGEST MARKET SHARE IN ASIA PACIFIC IN 2024

- FIGURE 18 INDIA TO REGISTER HIGHEST GROWTH DURING FORECAST PERIOD

- FIGURE 19 METALIZED FLEXIBLE PACKAGING MARKET: DRIVERS, RESTRAINTS, OPPORTUNITIES, AND CHALLENGES IN METALIZED FLEXIBLE PACKAGING MARKET

- FIGURE 20 YEAR-WISE INCREASING GLOBAL POPULATION, 2016-2024 (BILLION)

- FIGURE 21 YEAR-WISE RURAL VS. URBAN POPULATION, 2016-2030 (BILLION)

- FIGURE 22 GLOBAL B2B E-COMMERCE GMV, 2019-2026 (USD BILLION)

- FIGURE 23 E-COMMERCE MARKET CAGR, BY COUNTRY, 2023-2027

- FIGURE 24 GLOBAL BEAUTY MARKET, BY REGION, 2024

- FIGURE 25 GLOBAL BEAUTY MARKET, BY CATEGORY, 2024

- FIGURE 26 TRENDS/DISRUPTIONS IMPACTING CUSTOMER BUSINESS

- FIGURE 27 METALIZED FLEXIBLE PACKAGING MARKET: ECOSYSTEM ANALYSIS

- FIGURE 28 METALIZED FLEXIBLE PACKAGING MARKET: VALUE CHAIN ANALYSIS

- FIGURE 29 AVERAGE SELLING PRICE TREND OF METALIZED FLEXIBLE PACKAGING OFFERED BY KEY PLAYERS, 2024 (USD/KG)

- FIGURE 30 AVERAGE SELLING PRICE TREND OF METALIZED FLEXIBLE PACKAGING, BY REGION, 2021-2030 (USD/KG)

- FIGURE 31 EXPORT DATA FOR HS CODE 7607-COMPLIANT PRODUCTS, BY COUNTRY, 2020-2024 (USD MILLION)

- FIGURE 32 IMPORT DATA FOR HS CODE 7607-COMPLIANT PRODUCTS, BY COUNTRY, 2020-2024 (USD MILLION)

- FIGURE 33 LIST OF MAJOR PATENTS APPLIED AND GRANTED, 2015-2024

- FIGURE 34 MAJOR PATENTS APPLIED AND GRANTED, BY COUNTRY, 2015-2024

- FIGURE 35 INFLUENCE OF STAKEHOLDERS ON BUYING PROCESS, BY END-USE INDUSTRY

- FIGURE 36 BUYING CRITERIA FOR KEY END-USE INDUSTRIES

- FIGURE 37 INVESTOR DEALS AND FUNDING TREND, 2019-2024 (USD MILLION)

- FIGURE 38 IMPACT OF AI ON METALIZED FLEXIBLE PACKAGING MARKET

- FIGURE 39 PORTER'S FIVE FORCES ANALYSIS OF METALIZED FLEXIBLE PACKAGING MARKET

- FIGURE 40 FOOD SEGMENT TO DOMINATE MARKET DURING FORECAST PERIOD

- FIGURE 41 ALUMINUM-FOIL-BASED FLEXIBLE PACKAGING SEGMENT TO DOMINATE MARKET DURING FORECAST PERIOD

- FIGURE 42 POUCHES SEGMENT TO DOMINATE MARKET DURING FORECAST PERIOD

- FIGURE 43 LAMINATED STRUCTURES SEGMENT TO DOMINATE MARKET DURING FORECAST PERIOD

- FIGURE 44 INDIA TO BE FASTEST-GROWING MARKET DURING FORECAST PERIOD

- FIGURE 45 ASIA PACIFIC TO ACCOUNT FOR LARGEST SHARE OF METALIZED FLEXIBLE PACKAGING MARKET DURING FORECAST PERIOD

- FIGURE 46 ASIA PACIFIC: METALIZED FLEXIBLE PACKAGING MARKET SNAPSHOT

- FIGURE 47 NORTH AMERICA: METALIZED FLEXIBLE PACKAGING MARKET SNAPSHOT

- FIGURE 48 METALIZED FLEXIBLE PACKAGING MARKET: REVENUE ANALYSIS OF KEY PLAYERS, 2020-2024 (USD BILLION)

- FIGURE 49 METALIZED FLEXIBLE PACKAGING MARKET SHARE ANALYSIS, 2024

- FIGURE 50 COMPANY VALUATION (USD BILLION)

- FIGURE 51 FINANCIAL MATRIX: EV/EBITDA RATIO

- FIGURE 52 YEAR-TO-DATE PRICE AND FIVE-YEAR STOCK BETA

- FIGURE 53 METALIZED FLEXIBLE PACKAGING MARKET: BRAND/PRODUCT COMPARISON

- FIGURE 54 COMPANY EVALUATION MATRIX: KEY PLAYERS, 2024

- FIGURE 55 METALIZED FLEXIBLE PACKAGING MARKET: COMPANY FOOTPRINT

- FIGURE 56 COMPANY EVALUATION MATRIX: STARTUPS/SMES, 2024

- FIGURE 57 AMCOR PLC: COMPANY SNAPSHOT

- FIGURE 58 MONDI: COMPANY SNAPSHOT