PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1716618

PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1716618

Laser Welding Machine Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034

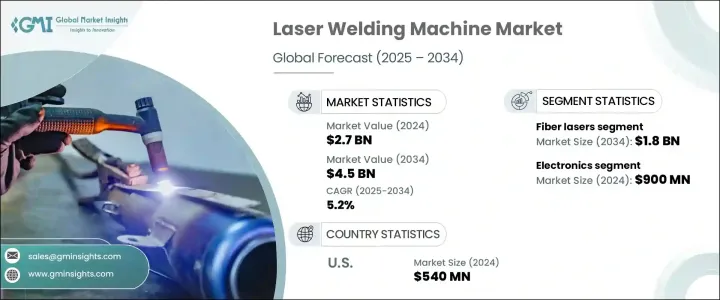

The Global Laser Welding Machine Market reached USD 2.7 billion in 2024 and is projected to grow at a CAGR of 5.2% between 2025 and 2034. The rising demand for high-precision manufacturing processes is driving the rapid expansion of this market, as industries such as automotive, aerospace, electronics, and medical devices continue to adopt advanced welding solutions. Laser welding technology has become an essential part of modern manufacturing for its unmatched accuracy, speed, and ability to create durable welds without compromising material integrity. With the surge in electric and autonomous vehicle production, the need for advanced welding systems that offer precision and efficiency is stronger than ever.

As companies focus on improving production capabilities and reducing downtime, laser welding machines are emerging as a critical component in enabling seamless, high-quality manufacturing. Moreover, the growing trend of miniaturization across various industries, especially electronics and medical devices, is pushing manufacturers to adopt non-contact welding solutions, as traditional methods often fall short of meeting the precision demands of next-generation products. Innovations in automation, coupled with Industry 4.0 advancements, are also fueling the adoption of laser welding machines, as manufacturers seek to streamline processes and enhance productivity. The increasing emphasis on sustainability and energy efficiency in manufacturing operations is another significant factor encouraging industries to shift toward laser welding technologies, given their ability to reduce waste, optimize material usage, and deliver consistent results.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $2.7 Billion |

| Forecast Value | $4.5 Billion |

| CAGR | 5.2% |

Laser welding technology is widely preferred over conventional welding methods for its superior precision, efficiency, and adaptability. The market is segmented by laser technology, with fiber lasers, CO2 lasers, diode lasers, and other variants forming the core product types. Among these, fiber lasers held a dominant share, valued at USD 1.2 billion in 2024, and are projected to reach USD 1.8 billion by 2034. Fiber lasers are highly favored across industries for their exceptional beam quality, energy efficiency, and reduced operational costs. These lasers are capable of welding intricate and delicate components without causing distortions, making them indispensable in sectors like automotive, medical device manufacturing, and electronics where precision is paramount.

Additionally, the market is segmented based on end-use industries, including automotive, medical, electronics, aerospace, and jewelry. The electronics segment, valued at USD 0.9 billion in 2024, is set to grow at a CAGR of 3.8% during the forecast period, driven by the demand for precision welding in compact and complex components such as semiconductors, circuit boards, and microelectronics.

The U.S. laser welding machine market, generating USD 540 million in 2024, is forecast to expand at a CAGR of 5.3% between 2025 and 2034, fueled by advancements in automation, electric vehicle manufacturing, and semiconductor production, making the U.S. a leading hub for fiber laser technology.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope & definition

- 1.2 Base estimates & calculations

- 1.3 Forecast parameters

- 1.4 Data sources

- 1.4.1 Primary

- 1.4.2 Secondary

- 1.4.2.1 Paid sources

- 1.4.2.2 Public sources

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis, 2021 - 2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Factors affecting the value chain

- 3.1.2 Profit margin analysis

- 3.1.3 Disruptions

- 3.1.4 Future outlook

- 3.1.5 Manufacturers

- 3.1.6 Distributors

- 3.1.7 Retailers

- 3.2 Impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Expansion of the automotive industry

- 3.2.1.2 Surge in manufacturing activities

- 3.2.1.3 Technological advancements in laser welding

- 3.2.2 Industry pitfalls & challenges

- 3.2.2.1 High initial investment and maintenance costs

- 3.2.2.2 Limited skilled workforce for operation and programming

- 3.2.1 Growth drivers

- 3.3 Technology & innovation landscape

- 3.4 Growth potential analysis

- 3.5 Regulatory landscape

- 3.6 Pricing analysis

- 3.7 Porter's analysis

- 3.8 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.3 Competitive positioning matrix

- 4.4 Strategic outlook matrix

Chapter 5 Market Estimates & Forecast, By Technology, 2021 – 2034, (USD Billion) (Million Units)

- 5.1 Key trends

- 5.2 Fiber lasers

- 5.3 CO2 lasers

- 5.4 Diode lasers

- 5.5 Others

Chapter 6 Market Estimates & Forecast, By End Use, 2021 – 2034, (USD Billion) (Million Units)

- 6.1 Key trends

- 6.2 Automotive

- 6.3 Medical

- 6.4 Electronics

- 6.5 Aerospace & defense

- 6.6 Jewelry

- 6.7 Others

Chapter 7 Market Estimates & Forecast, By Distribution Channel, 2021 – 2034, (USD Billion) (Million Units)

- 7.1 Key trends

- 7.2 Direct

- 7.3 Indirect

Chapter 8 Market Estimates & Forecast, By Region, 2021 – 2034, (USD Billion) (Million Units)

- 8.1 Key trends

- 8.2 North America

- 8.2.1 The U.S.

- 8.2.2 Canada

- 8.3 Europe

- 8.3.1 Germany

- 8.3.2 UK

- 8.3.3 France

- 8.3.4 Italy

- 8.3.5 Spain

- 8.3.6 Russia

- 8.4 Asia Pacific

- 8.4.1 China

- 8.4.2 India

- 8.4.3 Japan

- 8.4.4 South Korea

- 8.4.5 Australia

- 8.5 Latin America

- 8.5.1 Brazil

- 8.5.2 Mexico

- 8.6 MEA

- 8.6.1 Saudi Arabia

- 8.6.2 UAE

- 8.6.3 South Africa

Chapter 9 Company Profiles (Business Overview, Financial Data, Product Landscape, Strategic Outlook, SWOT Analysis)

- 9.1 CHIRON Group

- 9.2 Coherent

- 9.3 Emerson Electric

- 9.4 Han's Laser Technology Industry Group

- 9.5 Huagong Laser Engineering

- 9.6 IPG Photonics

- 9.7 Jenoptik

- 9.8 KEYENCE

- 9.9 Laser Technologies

- 9.10 Laser line

- 9.11 Laser Star Technologies

- 9.12 Penta Laser

- 9.13 Precitec

- 9.14 TRUMPF