PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1716601

PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1716601

Gas Fire Tube Industrial Boiler Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034

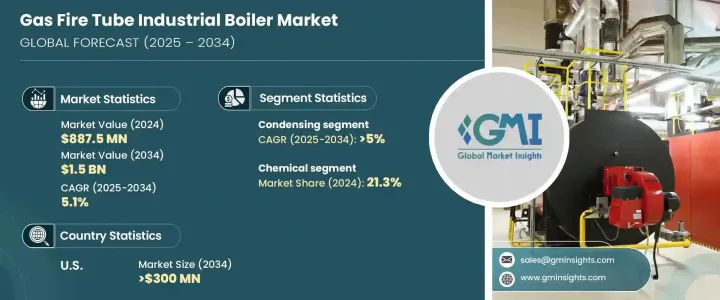

The Global Gas Fire Tube Industrial Boiler Market reached USD 887.5 million in 2024 and is projected to expand at a CAGR of 5.1% between 2025 and 2034. This growth is largely driven by the increasing pace of industrialization across key economies, coupled with rising investments in energy infrastructure. The shift towards cleaner energy sources, along with advancements in boiler technologies that focus on emissions reduction and enhanced efficiency, is expected to further boost the market.

The increasing trend towards remote monitoring and predictive maintenance solutions will continue to fuel demand for fire tube industrial boilers. This shift is aligned with the growing global focus on sustainable economic growth and the adoption of smart building management systems. In addition, continuous advancements in boiler technologies, such as digital monitoring and sophisticated combustion control systems, are likely to drive higher product adoption across industries. There is also a noticeable increase in investments aimed at developing high-efficiency boilers using sustainable, corrosion-resistant materials, which will open new opportunities for market players.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $887.5 Million |

| Forecast Value | $1.5 Billion |

| CAGR | 5.1% |

Industrial development, modernization, and a rising demand for efficient and reliable steam generation systems are set to further penetrate the market. Additionally, the emphasis on energy-efficient heating technologies, combined with the integration of digital technologies in boiler systems, will provide an enhanced outlook for the business. As the push for clean energy solutions intensifies, there is a growing demand for boilers that support these green initiatives, further contributing to market expansion.

The market is segmented by technology into condensing and non-condensing systems, both of which are gaining traction due to their minimal environmental impact, improved efficiency, and cost savings in heating. The condensing segment, in particular, is expected to grow steadily at a CAGR of over 5% until 2034, driven by higher energy costs and stricter environmental regulations. Government incentives and rebates for energy-efficient equipment will also play a key role in accelerating adoption.

In terms of application, the chemical sector led the market with a 21.3% share in 2024. The increasing infrastructure investments and adoption of high-efficiency boiler systems in emerging economies will continue to stimulate growth in this sector. In the U.S., the market for gas fire tube industrial boilers was valued at USD 192.2 million in 2022, growing to USD 213.3 million in 2024, and expected to surpass USD 300 million by 2034.

The North American market is expected to expand at a CAGR of over 4.5% due to stringent energy efficiency regulations and the implementation of climate change mitigation strategies. The region's adoption of corrosion-resistant materials in low-temperature systems and the development of industrial projects in high-altitude areas are likely to drive continued market growth.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope & definitions

- 1.2 Market estimates & forecast parameters

- 1.3 Forecast calculation

- 1.4 Data sources

- 1.4.1 Primary

- 1.4.2 Secondary

- 1.4.2.1 Paid

- 1.4.2.2 Public

Chapter 2 Executive Summary

- 2.1 Industry synopsis, 2021 - 2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.2 Regulatory landscape

- 3.3 Industry impact forces

- 3.3.1 Growth drivers

- 3.3.2 Industry pitfalls & challenges

- 3.4 Growth potential analysis

- 3.5 Porter's analysis

- 3.5.1 Bargaining power of suppliers

- 3.5.2 Bargaining power of buyers

- 3.5.3 Threat of new entrants

- 3.5.4 Threat of substitutes

- 3.6 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Strategic outlook

- 4.3 Innovation & sustainability landscape

Chapter 5 Market Size and Forecast, By Capacity, 2021 - 2034 (Units, MMBTU/hr & USD Million)

- 5.1 Key trends

- 5.2 < 10 MMBTU/hr

- 5.3 10 - 25 MMBTU/hr

- 5.4 25 - 50 MMBTU/hr

- 5.5 50 - 75 MMBTU/hr

- 5.6 > 75 MMBTU/hr

Chapter 6 Market Size and Forecast, By Application, 2021 - 2034 (Units, MMBTU/hr & USD Million)

- 6.1 Key trends

- 6.2 Food processing

- 6.3 Pulp & paper

- 6.4 Chemical

- 6.5 Refinery

- 6.6 Primary metal

- 6.7 Others

Chapter 7 Market Size and Forecast, By Technology, 2021 - 2034 (Units, MMBTU/hr & USD Million)

- 7.1 Key trends

- 7.2 Condensing

- 7.3 Non-condensing

Chapter 8 Market Size and Forecast, By Region, 2021 - 2034 (Units, MMBTU/hr & USD Million)

- 8.1 Key trends

- 8.2 North America

- 8.2.1 U.S.

- 8.2.2 Canada

- 8.2.3 Mexico

- 8.3 Europe

- 8.3.1 France

- 8.3.2 UK

- 8.3.3 Poland

- 8.3.4 Italy

- 8.3.5 Spain

- 8.3.6 Austria

- 8.3.7 Germany

- 8.3.8 Sweden

- 8.3.9 Russia

- 8.4 Asia Pacific

- 8.4.1 China

- 8.4.2 India

- 8.4.3 Philippines

- 8.4.4 Japan

- 8.4.5 South Korea

- 8.4.6 Australia

- 8.4.7 Indonesia

- 8.5 Middle East & Africa

- 8.5.1 Saudi Arabia

- 8.5.2 Iran

- 8.5.3 UAE

- 8.5.4 Nigeria

- 8.5.5 South Africa

- 8.6 Latin America

- 8.6.1 Brazil

- 8.6.2 Argentina

- 8.6.3 Chile

Chapter 9 Company Profiles

- 9.1 ALFA LAVAL

- 9.2 Babcock & Wilcox

- 9.3 Babcock Wanson

- 9.4 Clayton Industries

- 9.5 Cleaver-Brooks

- 9.6 EPCB Boiler

- 9.7 Fulton

- 9.8 Hurst Boiler & Welding

- 9.9 IHI Corporation

- 9.10 Johnston Boiler

- 9.11 Miura America

- 9.12 Rentech Boilers

- 9.13 Thermax

- 9.14 Thermodyne Boilers

- 9.15 Viessmann