PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1844384

PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1844384

Laser Processing Equipment Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034

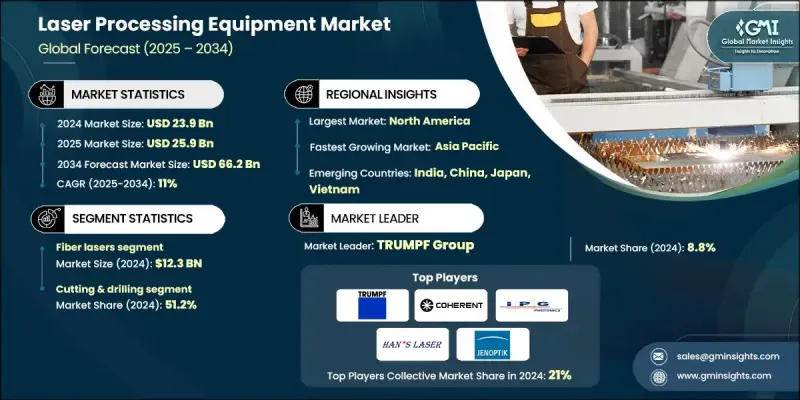

The Global Laser Processing Equipment Market was valued at USD 23.9 billion in 2024 and is estimated to grow at a CAGR of 11% to reach USD 66.2 billion by 2034.

The rapid integration of Industry 4.0 innovations, including AI, IoT, and full-scale automation, is reshaping industrial manufacturing and accelerating the adoption of advanced laser processing solutions. Fiber lasers continue gaining momentum due to their energy efficiency, reduced operating costs, and high reliability in demanding environments. Increasing use of laser-based additive manufacturing techniques has further propelled market growth as industries seek faster prototyping and greater design flexibility. Ultrafast and high-power lasers are also becoming essential across critical sectors like aerospace and medical, where accuracy and customization are vital. Rising expectations for precision, along with growing demand for sustainable manufacturing practices, are fostering continuous R&D. The industry's expansion is supported by scalable applications, such as micromachining, engraving, drilling, and structural cutting, all benefiting from precise, non-contact processing. These evolving use cases, coupled with favorable cost-to-performance ratios and an expanding industrial base, will continue to shape global market dynamics in the years to come.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $23.9 Billion |

| Forecast Value | $66.2 Billion |

| CAGR | 11% |

The fiber lasers category segment generated USD 12.3 billion in 2024, driven by their superior energy conversion efficiency and low maintenance requirements. Their consistent beam quality allows for detailed processing, which has become essential for high-tolerance operations across several advanced manufacturing environments. Reduced energy consumption translates into lower operational costs, making fiber lasers a preferred choice among cost-conscious industries. Their minimal material waste output and precision-focused performance align well with stricter production and sustainability standards being introduced across global manufacturing landscapes. Continuous improvements in fiber laser reliability and lifespan further enhance their adoption rate.

The cutting and drilling segment held a 51.2% share in 2024, driven by the need for intricate shaping and precise material removal. Laser processing is recognized for minimizing material wastage, supporting lean manufacturing models, and improving cost-efficiency. Its adaptability in handling metals, plastics, ceramics, and composite materials makes it a key tool across multiple verticals. From automotive assembly lines to medical device fabrication, the ability to perform complex operations with accuracy has cemented laser cutting and drilling as standard processes in modern industrial workflows.

U.S. Laser Processing Equipment Market held 65% and generated USD 3.5 billion in 2024. The country's innovation-focused ecosystem, combined with its advanced manufacturing infrastructure, continues to support product development and widespread adoption. The diversity of industries such as aerospace, electronics, automotive, and healthcare is driving consistent investment in next-generation laser technologies. Strong domestic R&D initiatives and the presence of global manufacturing leaders further reinforce the country's dominant position within the region.

Prominent companies shaping the Global Laser Processing Equipment Market include IPG Photonics, TRUMPF, Hans Group, Control Micro Systems, Vermont, Newport, Coherent, Rofin-Sinar Technologies, Lumibird, Universal Laser Systems, Eurolaser, Laser Systems, Concept Laser, Jenoptik, and Hgtech. Companies in the laser processing equipment market are strengthening their global footprint by focusing on innovation, efficiency, and sector-specific solutions. Many are investing heavily in R&D to develop compact, high-power laser systems tailored for precision industries. Customization and modular equipment designs are helping manufacturers cater to niche applications across the medical, aerospace, and electronics sectors. Strategic collaborations with OEMs and industrial automation providers are expanding the reach of their technologies. Firms are also scaling up production capabilities while emphasizing eco-friendly operations to meet the rising demand for sustainable manufacturing.

Table of Contents

Chapter 1 Methodology and Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 360° synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Technology type

- 2.2.3 Process level

- 2.2.4 Material type

- 2.2.5 Function type

- 2.2.6 Integration type

- 2.2.7 Laser source type

- 2.2.8 Cooling mechanism type

- 2.2.9 End use industry

- 2.3 CXO perspectives: Strategic imperatives

- 2.3.1 Key decision points for industry executives

- 2.3.2 Critical success factors for market players

- 2.4 Future outlook and strategic recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Advancements in laser technology

- 3.2.1.2 Growing demand for high-quality and precision manufacturing

- 3.2.1.3 Rising adoption of additive manufacturing (3D printing)

- 3.2.2 Industry pitfalls & challenges

- 3.2.2.1 High initial investments

- 3.2.2.2 Increased operating costs

- 3.2.3 Opportunities

- 3.2.3.1 (EVs) and Battery Manufacturing

- 3.2.3.2 Semiconductor and Microelectronics Fabrication

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Future market trends

- 3.5 Technology and innovation landscape

- 3.5.1 Current technological trends

- 3.5.2 Emerging technologies

- 3.6 Price trends

- 3.6.1 By region

- 3.6.2 By technology type

- 3.7 Regulatory landscape

- 3.7.1 Standards and compliance requirements

- 3.7.2 Regional regulatory frameworks

- 3.7.3 Certification standards

- 3.8 Trade statistics (HS code- 84561000)

- 3.8.1 Major importing countries

- 3.8.2 Major exporting countries

- 3.9 Porter’s analysis

- 3.10 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 Latin America

- 4.2.1.5 Middle East and Africa

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New product launches

- 4.6.4 Expansion plans

Chapter 5 Market Estimates & Forecast, By Technology Type, 2021-2034, (USD Billion) (Thousand Units)

- 5.1 Key trends

- 5.2 Fiber lasers

- 5.3 CO2

- 5.4 Solid state

- 5.5 Others

Chapter 6 Market Estimates & Forecast, By Process Type, 2021-2034, (USD Billion) (Thousand Units)

- 6.1 Key trends

- 6.2 Cutting & drilling

- 6.3 Welding

- 6.4 Marking & engraving

- 6.5 Punching & micromachining

- 6.6 Others

Chapter 7 Market Estimates & Forecast, By Material Type, 2021-2034, (USD Billion) (Thousand Units)

- 7.1 Key trends

- 7.2 Steel

- 7.3 Aluminium

- 7.4 Copper

- 7.5 Plastics and polymers

- 7.6 Ceramics

- 7.7 Others (Glass, composites, semiconductors etc.)

Chapter 8 Market Estimates & Forecast, By Function Type, 2021-2034, (USD Billion) (Thousand Units)

- 8.1 Key trends

- 8.2 Semi-automatic

- 8.3 Automatic

Chapter 9 Market Estimates & Forecast, By Integration Level, 2021-2034, (USD Billion) (Thousand Units)

- 9.1 Key trends

- 9.2 Standalone systems

- 9.3 Integrated production lines

- 9.4 Modular systems

- 9.5 Portable/desktop units

Chapter 10 Market Estimates & Forecast, By Laser Source Type, 2021-2034, (USD Billion) (Thousand Units)

- 10.1 Key trends

- 10.2 Diode lasers

- 10.3 Disk lasers

- 10.4 Excimer lasers

- 10.5 Others (Ultrafast lasers, thulium)

Chapter 11 Market Estimates & Forecast, By Cooling Mechanism, 2021-2034, (USD Billion) (Thousand Units)

- 11.1 Key trends

- 11.2 Air-cooled

- 11.3 Water-cooled

- 11.4 Hybrid cooling

Chapter 12 Market Estimates & Forecast, By End Use, 2021-2034, (USD Billion) (Thousand Units)

- 12.1 Key trends

- 12.2 Automotive

- 12.3 Metal & fabrication

- 12.4 Electronics

- 12.5 Energy & power

- 12.6 Others

Chapter 13 Market Estimates & Forecast, By Region, 2021-2034, (USD Billion) (Thousand Units)

- 13.1 Key trends

- 13.2 North America

- 13.2.1 U.S.

- 13.2.2 Canada

- 13.3 Europe

- 13.3.1 Germany

- 13.3.2 UK

- 13.3.3 France

- 13.3.4 Spain

- 13.3.5 Italy

- 13.4 Asia Pacific

- 13.4.1 China

- 13.4.2 Japan

- 13.4.3 India

- 13.4.4 Australia

- 13.4.5 South Korea

- 13.5 Latin America

- 13.5.1 Brazil

- 13.5.2 Mexico

- 13.5.3 Argentina

- 13.6 Middle East and Africa

- 13.6.1 South Africa

- 13.6.2 Saudi Arabia

- 13.6.3 UAE

Chapter 14 Company Profiles

- 14.1 Coherent

- 14.2 Concept Laser

- 14.3 Control Micro Systems

- 14.4 Eurolaser

- 14.5 Hans Group

- 14.6 Hgtech

- 14.7 IPG Photonics

- 14.8 Jenoptik

- 14.9 Laser Systems

- 14.10 Lumibird

- 14.11 Newport

- 14.12 Rofin-Sinar Technologies

- 14.13 TRUMPF

- 14.14 Universal Laser Systems

- 14.15 Vermont