PUBLISHER: Coherent Market Insights | PRODUCT CODE: 1708798

PUBLISHER: Coherent Market Insights | PRODUCT CODE: 1708798

Global Automotive Fascia Market, By Sales Channel, By Position, By Vehicle Type, By Geography

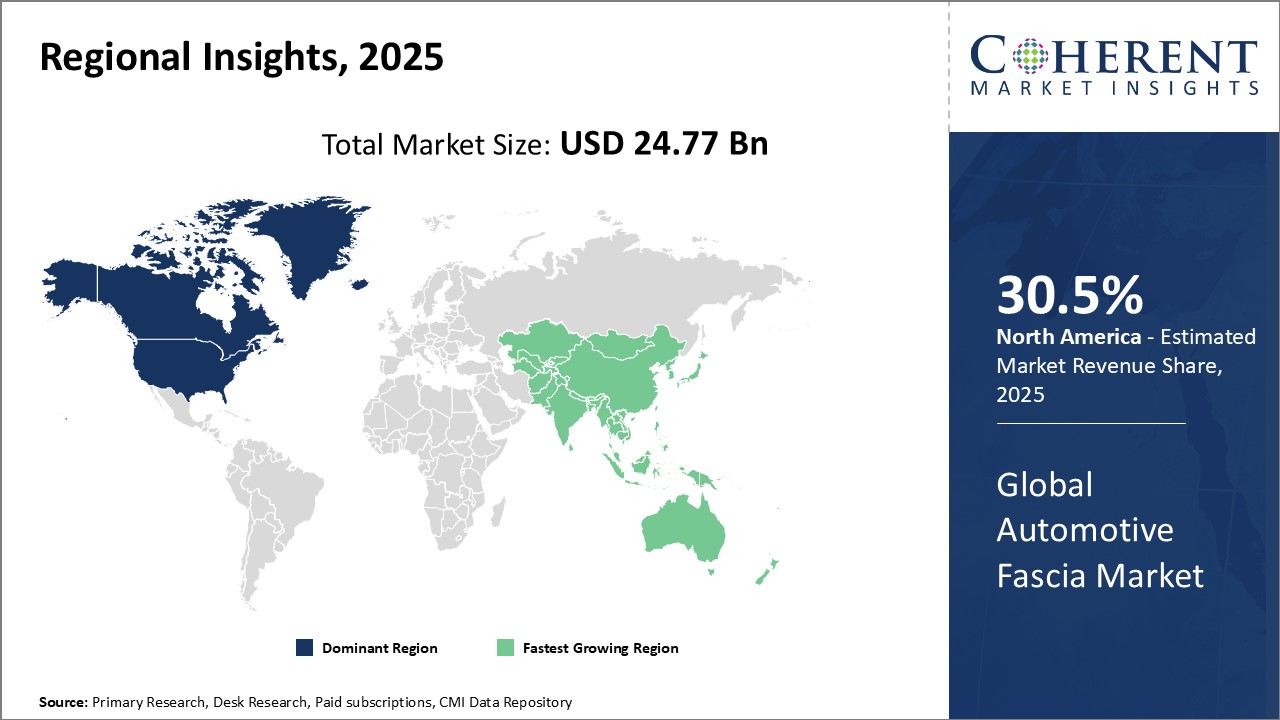

Global Automotive Fascia Market is estimated to be valued at USD 24.77 Bn in 2025 and is expected to reach USD 35.58 Bn by 2032, growing at a compound annual growth rate (CAGR) of 5.3% from 2025 to 2032.

| Report Coverage | Report Details | ||

|---|---|---|---|

| Base Year: | 2024 | Market Size in 2025: | USD 24.77 Bn |

| Historical Data for: | 2020 To 2024 | Forecast Period: | 2025 To 2032 |

| Forecast Period 2025 to 2032 CAGR: | 5.30% | 2032 Value Projection: | USD 35.58 Bn |

The global automotive fascia market has been witnessing significant growth over the past few years owing to the rising automobile production across the world. Automotive fascias, commonly known as the front bumper, are exterior automotive body parts located at the front of vehicles. They are designed to absorb impact in case of minor crashes and protect essential vehicle parts. With the increasing demand for passenger cars as well as commercial vehicles, automakers are focusing on developing innovative and aesthetic fascia designs to enhance the looks of vehicles. Moreover, the growing popularity of Sports Utility Vehicles (SUVs) and crossover vehicles among consumers have also boosted the sales of automotive fascias globally. Several manufacturers are introducing advanced materials like composites and plastics to manufacture lightweight yet durable fascias. With technological advancements, the automotive fascia market is expected to continue its growth trajectory over the forecast period.

Market Dynamics:

The global automotive fascia market is driven by factors such as rising vehicle production, increasing demand for aesthetically designed vehicles, and technological advancements in fascia materials. Rapid urbanization, growing income levels, and improving lifestyles in developing nations have boosted the sales of passenger cars in recent years. This is expected to positively influence the demand for automotive fascias. However, high research and development costs associated with advanced fascia designs could hamper the market growth. On the other hand, the advent of 3D printing technology has opened up new opportunities for manufacturing complex-shaped lightweight fascias. OEMs are also exploring the potential of recyclable and bio-based materials for automotive fascia manufacturing. This could help reduce production costs and minimize the environmental impact.

Key features of the study:

- This report provides an in-depth analysis of the global automotive fascia market, and provides market size (US$ Billion) and compound annual growth rate (CAGR %) for the forecast period (2025-2032), considering 2024 as the base year.

- It elucidates potential revenue growth opportunities across different segments and explains attractive investment proposition matrices for this market.

- This study also provides key insights about market drivers, restraints, opportunities, new product launches or approval, market trends, regional outlook, and competitive strategies adopted by key players.

- It profiles key players in the global automotive fascia market based on the following parameters - company highlights, products portfolio, key highlights, financial performance, and strategies.

- Key companies covered as a part of this study include Magna International, Inhance Technologies, Flex-N-Gate Corporation, Dongfeng Electronic Technology Co. Ltd., Eakas Corporation, MRC Manufacturing, Chiyoda Manufacturing, Sanko GOSEI, Gestamp Automocion, Plastic Omnium, Aisin Corporation, Dakkota Integrated System LLC, Revere Plastics System, Guardian Industries, Samvardhana Motherson, Toyoda Gosei.

- Insights from this report would allow marketers and the management authorities of the companies to make informed decisions regarding their future product launches, type up-gradation, market expansion, and marketing tactics.

- The global automotive fascia market report caters to various stakeholders in this industry including investors, suppliers, product manufacturers, distributors, new entrants, and financial analysts.

- Stakeholders would have ease in decision-making through various strategy matrices used in analyzing the global automotive fascia market.

Market Segmentation

- By Sales Channel

- OEM

- Aftermarket

- By Position

- Front Facia

- Rear Facia

- By Vehicle Type

- Passenger Vehicle

- Commercial Vehicle

- By Regional

- North America

- Latin America

- Europe

- Asia Pacific

- Middle East & Africa

- Key Players insights

- Magna International

- Inhance Technologies

- Flex-N-Gate Corporation

- Dongfeng Electronic Technology Co. Ltd.

- Eakas Corporation

- MRC Manufacturing

- Chiyoda Manufacturing

- Sanko GOSEI

- Gestamp Automocion

- Plastic Omnium

- Aisin Corporation

- Dakkota Integrated System LLC

- Revere Plastics System

- Guardian Industries

- Samvardhana Motherson

- Toyoda Gosei

Table of Contents

1. Research Objectives and Assumptions

- Research Objectives

- Assumptions

- Abbreviations

2. Market Purview

- Report Description

- Market Definition and Scope

- Executive Summary

- Market Snippet, By Sales Channel

- Market Snippet, By Position

- Market Snippet, By Vehicle Type

- Market Snippet, By Region

- Coherent Opportunity Map (COM)

3. Market Dynamics, Regulations, and Trends Analysis

- Market Dynamics

- Drivers

- Restraints

- Opportunities

- Regulatory Scenario

- Industry Trend

- Merger and Acquisitions

- New System Launches/Approvals

- Impact of the COVID-19 Pandemic

4. Global Automotive Fascia Market, By Sales Channel, 2020-2032 (US$ Billion)

- Introduction

- Market Share Analysis, 2025 and 2032 (%)

- Y-o-Y Growth Analysis, 2020-2032

- Segment Trends

- OEM

- Introduction

- Market Size and Forecast, 2020-2032, (US$ Billion)

- Aftermarket

- Introduction

- Market Size and Forecast, 2020-2032, (US$ Billion)

5. Global Automotive Fascia Market, By Position, 2020-2032 (US$ Billion)

- Introduction

- Market Share Analysis, 2025 and 2032 (%)

- Y-o-Y Growth Analysis, 2020-2032

- Segment Trends

- Front Facia

- Introduction

- Market Size and Forecast, 2020-2032, (US$ Billion)

- Rear Facia

- Introduction

- Market Size and Forecast, 2020-2032, (US$ Billion)

6. Global Automotive Fascia Market, By Vehicle Type, 2020-2032 (US$ Billion)

- Introduction

- Market Share Analysis, 2025 and 2032 (%)

- Y-o-Y Growth Analysis, 2020-2032

- Segment Trends

- Passenger Vehicle

- Introduction

- Market Size and Forecast, 2020-2032, (US$ Billion)

- Commercial Vehicle

- Introduction

- Market Size and Forecast, 2020-2032, (US$ Billion)

7. Global Automotive Fascia Market, By Region, 2020-2032 (US$ Billion)

- Introduction

- Market Share Analysis, By Region, 2025 and 2032 (%)

- Y-o-Y Growth Analysis, 2020-2032

- North America

- Regional Trends

- Market Size and Forecast, By Sales Channel, 2020-2032 (US$ Billion)

- Market Size and Forecast, By Position, 2020-2032 (US$ Billion)

- Market Size and Forecast, By Vehicle Type, 2020-2032 (US$ Billion)

- Market Share Analysis, By Country, 2020 and 2032 (%)

- U.S.

- Canada

- Europe

- Regional Trends

- Market Size and Forecast, By Sales Channel, 2020-2032 (US$ Billion)

- Market Size and Forecast, By Position, 2020-2032 (US$ Billion)

- Market Size and Forecast, By Vehicle Type, 2020-2032 (US$ Billion)

- Market Share Analysis, By Country, 2020 and 2032 (%)

- U.K.

- Germany

- Italy

- France

- Russia

- Rest of Europe

- Asia Pacific

- Regional Trends

- Market Size and Forecast, By Sales Channel, 2020-2032 (US$ Billion)

- Market Size and Forecast, By Position, 2020-2032 (US$ Billion)

- Market Size and Forecast, By Vehicle Type, 2020-2032 (US$ Billion)

- Market Share Analysis, By Country, 2020 and 2032 (%)

- China

- India

- ASEAN

- Australia

- South Korea

- Japan

- Rest of Asia Pacific

- Latin America

- Regional Trends

- Market Size and Forecast, By Sales Channel, 2020-2032 (US$ Billion)

- Market Size and Forecast, By Position, 2020-2032 (US$ Billion)

- Market Size and Forecast, By Vehicle Type, 2020-2032 (US$ Billion)

- Market Share Analysis, By Country, 2020 and 2032 (%)

- Brazil

- Argentina

- Mexico

- Rest of Latin America

- Middle East & Africa

- Regional Trends

- Market Size and Forecast, By Sales Channel, 2020-2032 (US$ Billion)

- Market Size and Forecast, By Position, 2020-2032 (US$ Billion)

- Market Size and Forecast, By Vehicle Type, 2020-2032 (US$ Billion)

- Market Share Analysis, By Country, 2020 and 2032 (%)

- GCC Countries

- South Africa

- Rest of the Middle East & Africa

8. Competitive Landscape

- Company Profiles

- Magna International

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Inhance Technologies

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Flex-N-Gate Corporation

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Dongfeng Electronic Technology Co. Ltd

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates.

- Eakas Corporation

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- MRC Manufacturing

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Chiyoda Manufacturing

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Sanko GOSEI

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Gestamp Automocion

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Plastic Omnium

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Aisin Corporation

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Dakkota Integrated System LLC

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Revere Plastics System

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Guardian Industries

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Samvardhana Motherson

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Toyoda Gosei

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Magna International

9. Analyst Recommendations

- Wheel of Fortune

- Analyst View

- Coherent Opportunity Map

10. Research Methodology

- References

- Research Methodology

- About us and Sales Contact