PUBLISHER: Coherent Market Insights | PRODUCT CODE: 1708485

PUBLISHER: Coherent Market Insights | PRODUCT CODE: 1708485

Refractories Market, By Form, By Product, By Alkalinity, By End-Use Industry, By Geography

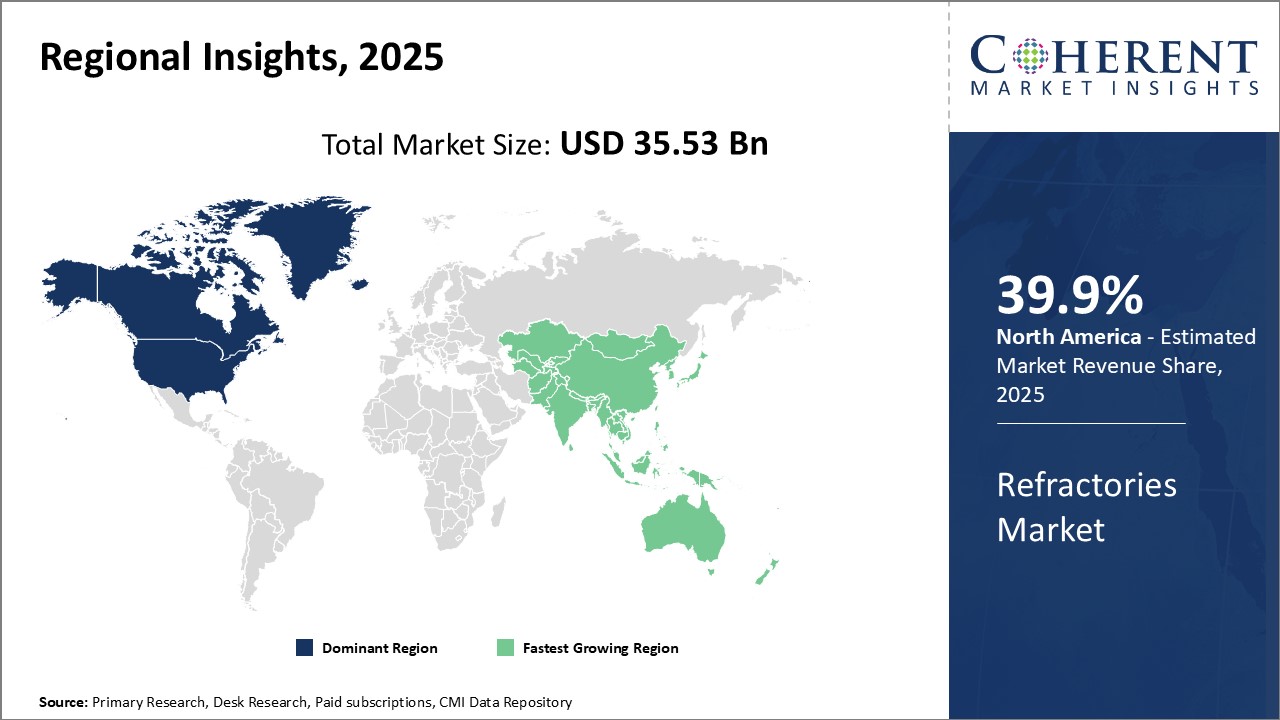

Global Refractories Market is estimated to be valued at USD 35.53 Bn in 2025 and is expected to reach USD 47.11 Bn by 2032, growing at a compound annual growth rate (CAGR) of 4.1% from 2025 to 2032.

| Report Coverage | Report Details | ||

|---|---|---|---|

| Base Year: | 2024 | Market Size in 2025: | USD 35.53 Bn |

| Historical Data for: | 2020 To 2024 | Forecast Period: | 2025 To 2032 |

| Forecast Period 2025 to 2032 CAGR: | 4.10% | 2032 Value Projection: | USD 47.11 Bn |

Refractories are heat-resistant materials that are widely used in various industries such as iron and steel, cement, nonferrous metals, glass, and others to line furnaces, reactors, and kilns.

Refractories are heat-resistant materials that are widely used in applications involving high temperatures, especially for making furnace linings. They maintain their strength and chemical composition even when subjected to extreme heating and cooling cycles and help provide thermal insulation. Refractories serve an essential function in various industrial processes like steel production, cement and lime making, glass manufacture, non-ferrous metal production, and petrochemical industries. The global refractories market has experienced steady growth over the years due to the expansion of the core industries where they are utilized. However, increased energy costs, stringent environmental regulations, and shifting focus towards alternative materials present some challenges.

Market Dynamics:

The global refractories market is driven by robust growth in steel production supported by strong economic development worldwide. Refractories have immense importance in steel manufacturing as all types of steel-making furnaces that depend on suitable refractory lining materials to maintain operations. Surging steel demand from developing countries is fueling the consumption of refractories. However, rising energy prices have increased manufacturing costs for many core industries, which, in turn, exerts pricing pressure on refractory producers. Burgeoning climate change concerns are also prompting industries to reduce greenhouse gas emissions from refractory manufacturing. Furthermore, the development of novel lightweight and energy-efficient alternative materials poses a threat to traditional refractories. On the positive side, advancements in material technology are enabling the production of improved performance refractories. Emerging applications in renewable energy industries also present new opportunities for market expansion.

Key features of the study:

- This report provides an in-depth analysis of the global refractories market, and provides market size (US$ Billion) and compound annual growth rate (CAGR %) for the forecast period (2025-2032), considering 2024 as the base year

- It elucidates potential revenue growth opportunities across different segments and explains attractive investment proposition matrices for this market

- This study also provides key insights about market drivers, restraints, opportunities, new product launches or approval, market trends, regional outlook, and competitive strategies adopted by key players

- It profiles key players in the global refractories market based on the following parameters - company highlights, products portfolio, key highlights, financial performance, and strategies

- Key companies covered as a part of this study include Vesuvius, RHI Magnesita, Krosaki Harima, Shinagawa Refractories, Saint-Gobain, Corning Incorporated, Morgan Advanced Materials, Coorstek, and Chosun Refractories

- Insights from this report would allow marketers and the management authorities of the companies to make informed decisions regarding their future product launches, type up-gradation, market expansion, and marketing tactics

- The global refractories market report caters to various stakeholders in this industry including investors, suppliers, product manufacturers, distributors, new entrants, and financial analysts

Detailed Segmentation

- By Form

- Bricks & Shaped'

- Monolithic & Unshaped

- By Product

- Clay

- Non-Clay

- By Alkalinity

- Acidic & Neutral

- Basic

- By End-use Industry

- Iron & Steel

- Non-Ferrous Metals

- Glass

- Cement

- Others

- By Regional

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East

- Africa

- Company Profiles

- Morgan Advanced Materials plc

- Corning Incorporated

- Shinagawa Refractories

- Saint-Gobain

- RHI Magnesia

- Minera; Technologies Inc.

- Imerys

- Sibelco

- Refratechnik Holding GmbH

- Krosaki Harima Corporation

- INTOCAST AG

- Plibrico Company, LLC

- EXUS Refractories S.p.A

- Pyrol

- Redline Industries, Inc.

- HarbisonWalker International

- Vesuvius plc

- Resco Products, Inc.

- Calderys

- Krosaki Harima Corporation

- Imerys Group

Table of Contents

1. Research Objectives and Assumptions

- Research Objectives

- Assumptions

- Abbreviations

2. Market Purview

- Report Description

- Market Definition and Scope

- Executive Summary

- Market Snippet, By Form

- Market Snippet, By Product

- Market Snippet, By Alkalinity

- Market Snippet, By End-Use Industry

- Market Snippet, By Region

- Coherent Opportunity Map (COM)

3. Market Dynamics, Regulations, and Trends Analysis

- Market Dynamics

- Drivers

- Restraints

- Opportunities

- Regulatory Scenario

- Industry Trend

- Merger and Acquisitions

- New system Launch/Approvals

- Impact of the COVID-19 Pandemic

4. Global Refractories Market, By Form, 2020-2032, (US$ Billion)

- Introduction

- Market Share Analysis, 2025 and 2032 (%)

- Y-o-Y Growth Analysis, 2020-2032

- Segment Trends

- Bricks & Shaped

- Introduction

- Market Size and Forecast, 2020-2032, (US$ Billion)

- Monolithic & Unshaped

- Introduction

- Market Size and Forecast, 2020-2032, (US$ Billion)

5. Global Refractories Market, By Product, 2020-2032, (US$ Billion)

- Introduction

- Market Share Analysis, 2025 and 2032 (%)

- Segment Trends

- Clay

- Introduction

- Market Size and Forecast, 2020-2032, (US$ Billion)

- Non-Clay

- Introduction

- Market Size and Forecast, 2020-2032, (US$ Billion)

6. Global Refractories Market, By Alkalinity, 2020-2032, (US$ Billion)

- Introduction

- Market Share Analysis, 2025 and 2032 (%)

- Segment Trends

- Acidic & Neutral

- Introduction

- Market Size and Forecast, 2020-2032, (US$ Billion)

- Basic

- Introduction

- Market Size and Forecast, 2020-2032, (US$ Billion)

7. Global Refractories Market, By End-Use Industry, 2020-2032, (US$ Billion)

- Introduction

- Market Share Analysis, 2025 and 2032 (%)

- Segment Trends

- Iron & Steel

- Introduction

- Market Size and Forecast, 2020-2032, (US$ Billion)

- Non-Ferrous Metals

- Introduction

- Market Size and Forecast, 2020-2032, (US$ Billion)

- Glass

- Introduction

- Market Size and Forecast, 2020-2032, (US$ Billion)

- Cement

- Introduction

- Market Size and Forecast, 2020-2032, (US$ Billion)

- Others

- Introduction

- Market Size and Forecast, 2020-2032, (US$ Billion)

8. Global Refractories Market, By Region, 2020-2032, (US$ Billion)

- Introduction

- Market Share Analysis, By Region, 2025 and 2032 (%)

- Y-o-Y Growth Analysis, 2020-2032

- North America

- Regional Trends

- Market Size and Forecast, By Form, 2020-2032, (US$ Billion)

- Market Size and Forecast, By Product, 2020-2032, (US$ Billion)

- Market Size and Forecast, By Alkalinity, 2020-2032, (US$ Billion)

- Market Size and Forecast, By End-Use Industry, 2020-2032, (US$ Billion)

- Market Size and Forecast, By Country, 2020-2032, (US$ Billion)

- U.S.

- Canada

- Europe

- Regional Trends

- Market Size and Forecast, By Form, 2020-2032, (US$ Billion)

- Market Size and Forecast, By Product, 2020-2032, (US$ Billion)

- Market Size and Forecast, By Alkalinity, 2020-2032, (US$ Billion)

- Market Size and Forecast, By End-Use Industry, 2020-2032, (US$ Billion)

- Market Size and Forecast, By Country, 2020-2032, (US$ Billion)

- U.K.

- Germany

- Italy

- France

- Russia

- Rest of Europe

- Asia Pacific

- Regional Trends

- Market Size and Forecast, By Form, 2020-2032, (US$ Billion)

- Market Size and Forecast, By Product, 2020-2032, (US$ Billion)

- Market Size and Forecast, By Alkalinity, 2020-2032, (US$ Billion)

- Market Size and Forecast, By End-Use Industry, 2020-2032, (US$ Billion)

- Market Size and Forecast, By Country, 2020-2032, (US$ Billion)

- China

- India

- ASEAN

- Australia

- South Korea

- Japan

- Rest of Asia Pacific

- Latin America

- Regional Trends

- Market Size and Forecast, By Form, 2020-2032, (US$ Billion)

- Market Size and Forecast, By Product, 2020-2032, (US$ Billion)

- Market Size and Forecast, By Alkalinity, 2020-2032, (US$ Billion)

- Market Size and Forecast, By End-Use Industry, 2020-2032, (US$ Billion)

- Market Size and Forecast, By Country, 2020-2032, (US$ Billion)

- Brazil

- Argentina

- Mexico

- Rest of Latin America

- Middle East & Africa

- Regional Trends

- Market Size and Forecast, By Form, 2020-2032, (US$ Billion)

- Market Size and Forecast, By Product, 2020-2032, (US$ Billion)

- Market Size and Forecast, By Alkalinity, 2020-2032, (US$ Billion)

- Market Size and Forecast, By End-Use Industry, 2020-2032, (US$ Billion)

- Market Size and Forecast, By Country, 2020-2032, (US$ Billion)

- GCC Countries

- South Africa

- Rest of the Middle East & Africa

9. Competitive Landscape

- Company Profiles

- Morgan Advanced Materials plc

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Corning Incorporated

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Shinagawa Refractories

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Saint-Gobain

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- RHI Magnesia

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Minera; Technologies Inc.

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Imerys

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Sibelco

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Refratechnik Holding GmbH

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Krosaki Harima Corporation INTOCAST AG

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Plibrico Company, LLC

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- EXUS Refractories S.p.A

- Pyrol

- Redline Industries, Inc.

- HarbisonWalker International

- Vesuvius plc

- Resco Products, Inc.

- Calderys

- Krosaki Harima Corporation

- Imerys Group

- Morgan Advanced Materials plc

10. Analyst Recommendations

- Wheel of Fortune

- Analyst View

- Coherent Opportunity Map

11. Research Methodology

- References

- Research Methodology

- About us and Sales Contact