PUBLISHER: Aviation & Defense Market Reports (A&D) | PRODUCT CODE: 1714098

PUBLISHER: Aviation & Defense Market Reports (A&D) | PRODUCT CODE: 1714098

Global Iron bird test setups Market 2025-2035

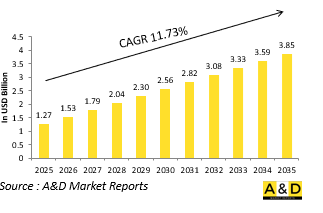

The Global Iron bird test setups market is estimated at USD 1.27 billion in 2025, projected to grow to USD 3.85 billion by 2035 at a Compound Annual Growth Rate (CAGR) of 11.73% over the forecast period 2025-2035.

Introduction to Iron bird test setups Market:

Iron bird test setups serve as an essential part of aircraft system development and integration in the defense sector. These test beds are ground-based platforms that replicate the structural and functional layout of an aircraft or airframe, enabling engineers to conduct full-scale testing of systems such as hydraulics, avionics, electrical wiring, flight control mechanisms, and software integration long before the first flight. In defense applications, iron birds are critical in reducing technical risks during the development of advanced fighters, transport aircraft, unmanned aerial vehicles (UAVs), and rotorcraft. Unlike computer simulations or isolated component tests, iron bird setups allow for physical verification of the interplay between complex subsystems, revealing issues like hydraulic line interference, control logic faults, or electrical signal timing errors. They also provide a safe environment to rehearse operational scenarios, simulate in-flight failures, and evaluate maintenance accessibility-particularly important in military platforms where mission readiness and safety are paramount. Iron birds are often used from the early engineering phases through late-stage validation, evolving to reflect configuration changes and incorporating actual production parts as they become available. Their role is indispensable in ensuring system maturity and integration before actual flight testing begins, saving time, costs, and mitigating mission-critical failures in defense aviation programs.

Technology Impact in Iron bird test setups Market:

Advancements in digital engineering, systems integration, and sensor instrumentation are significantly transforming iron bird test setups in defense aerospace. One of the most impactful developments is the integration of digital twins, which create real-time digital replicas of physical systems that operate in sync with the iron bird's behavior. This allows for advanced modeling, predictive maintenance, and control system optimization during ground testing. Fly-by-wire and fly-by-light systems, increasingly used in next-generation defense platforms, have necessitated new iron bird architectures that can simulate and validate complex signal processing and software-defined control laws. High-fidelity motion actuators and servo-hydraulic systems are now embedded into iron bird rigs to simulate aerodynamic forces and mechanical responses under dynamic flight loads, enabling realistic testing of control surfaces and power-assisted systems. Additionally, modular test racks equipped with plug-and-play capability allow teams to rapidly swap avionics packages and subsystems for comparative evaluation. Data acquisition has also been revolutionized with high-speed telemetry, real-time monitoring dashboards, and integrated analytics platforms that feed data into simulation loops. Some advanced setups now support hardware-in-the-loop (HIL) and software-in-the-loop (SIL) interfaces, enabling concurrent testing of embedded software and system hardware in mission-like environments. These technologies are not only improving test accuracy and coverage but also significantly reducing turnaround times between system iterations.

Key Drivers in Iron bird test setups Market:

Several strategic and operational imperatives are driving the expansion and sophistication of iron bird test setups in the global defense industry. First and foremost is the escalating complexity of modern defense aircraft, which integrate a multitude of systems-from stealthy avionics and electronic warfare modules to adaptive flight control software and networked communication nodes. Verifying that these systems function harmoniously before live flight is no longer optional but essential, and iron bird setups are the most effective tools for holistic integration and troubleshooting. Another major driver is the increased pressure to shorten development timelines and reduce program costs in competitive defense markets. By resolving integration issues early in the development cycle, iron bird tests help avoid expensive redesigns and costly in-flight anomalies, which can derail program schedules. The growing emphasis on modular and upgradeable platforms-especially for fighters, UAVs, and multirole aircraft-requires flexible test beds that can validate new configurations without the need for new prototypes. Furthermore, as defense programs increasingly involve international collaboration, joint ventures and multinational platforms such as the F-35 or FCAS necessitate standardized and scalable testing environments that can accommodate input from multiple suppliers. Lastly, iron bird setups support training and maintenance protocol validation, enabling logistics and maintenance teams to rehearse fault diagnosis and component replacement before field deployment. These drivers collectively underscore the rising strategic value of iron bird test setups in military aviation R&D and acquisition frameworks.

Regional Trends in Iron bird test setups Market:

The evolution of iron bird test capabilities varies by region, reflecting local defense priorities, aerospace infrastructure, and industrial maturity. In North America, the United States remains a global leader in iron bird implementation, with advanced test facilities maintained by OEMs like Lockheed Martin, Boeing, and Northrop Grumman. These setups support an array of programs from sixth-generation fighters to long-range bombers and tactical drones, often with HIL integration and support for live software patches. The U.S. Department of Defense (DoD) emphasizes rapid prototyping and integration, prompting the use of multiple iron bird configurations to parallel-track component maturity. Canada, while more focused on support roles, leverages iron bird testing through partnerships with American firms and government research agencies for its aerial surveillance and logistics platforms. In Europe, leading aerospace nations such as Germany, France, and the UK invest in iron bird capabilities to support collaborative programs like Tempest and FCAS, with test setups tailored for modularity and real-time data exchange among partner firms. European iron birds also play a key role in validating sustainable propulsion systems and hybrid-electric configurations. In Asia-Pacific, China has rapidly advanced its iron bird infrastructure to support the development of indigenous fighters, transport aircraft, and stealth drones. Chinese setups often emphasize independent sensor fusion and powertrain integration under cybersecure conditions. India, with HAL and DRDO at the forefront, is enhancing its iron bird capabilities for platforms like Tejas, AMCA, and Ghatak UCAV, with a growing emphasis on modular avionics and flight software debugging. Japan and South Korea are deploying advanced iron bird testbeds to support stealth fighters and surveillance aircraft, with particular focus on export compliance and interoperability. In the Middle East, nations like the UAE and Saudi Arabia are building foundational iron bird infrastructure to support joint aerospace manufacturing and MRO (maintenance, repair, overhaul) capabilities under national defense industrialization goals. Across regions, the trend is clear: iron bird setups are becoming more digitally connected, modular, and aligned with agile development principles, enabling faster, safer, and more efficient defense aviation programs worldwide.

Key Iron bird test setups Program:

Boeing has been awarded the Engineering and Manufacturing Development (EMD) contract for the U.S. Air Force's Next-Generation Air Dominance (NGAD) fighter jet program. In an announcement made from the Oval Office, President Donald Trump, Defense Secretary Pete Hegseth, and Air Force Chief General David Allvin confirmed that the new aircraft will be designated the F-47-marking the United States' first sixth-generation fighter. This milestone marks Boeing's first "clean-sheet" fighter design to be selected since its 1997 merger with McDonnell Douglas. Unlike aircraft such as the F-15EX, which are based on legacy McDonnell Douglas platforms, a clean-sheet design begins entirely from scratch, tailored specifically to meet the mission requirements and vision of the customer.

Table of Contents

Global Iron bird test setups in defense- Table of Contents

Global Iron bird test setups in defense Report Definition

Global Iron bird test setups in defense Segmentation

By Region

By Type

By Platform

By Test

Global Iron bird test setups in defense Analysis for next 10 Years

The 10-year Global Iron bird test setups in defense analysis would give a detailed overview of Global Iron bird test setups in defense growth, changing dynamics, technology adoption overviews and the overall market attractiveness is covered in this chapter.

Market Technologies of Global Iron bird test setups in defense

This segment covers the top 10 technologies that is expected to impact this market and the possible implications these technologies would have on the overall market.

Global Iron bird test setups in defense Forecast

The 10-year Global Iron bird test setups in defense forecast of this market is covered in detailed across the segments which are mentioned above.

Regional Global Iron bird test setups in defense Trends & Forecast

The regional counter drone market trends, drivers, restraints and Challenges of this market, the Political, Economic, Social and Technology aspects are covered in this segment. The market forecast and scenario analysis across regions are also covered in detailed in this segment. The last part of the regional analysis includes profiling of the key companies, supplier landscape and company benchmarking. The current market size is estimated based on the normal scenario.

North America

Drivers, Restraints and Challenges

PEST

Market Forecast & Scenario Analysis

Key Companies

Supplier Tier Landscape

Company Benchmarking

Europe

Middle East

APAC

South America

Country Analysis of Global Iron bird test setups in defense

This chapter deals with the key defense programs in this market, it also covers the latest news and patents which have been filed in this market. Country level 10 year market forecast and scenario analysis are also covered in this chapter.

US

Defense Programs

Latest News

Patents

Current levels of technology maturation in this market

Market Forecast & Scenario Analysis

Canada

Italy

France

Germany

Netherlands

Belgium

Spain

Sweden

Greece

Australia

South Africa

India

China

Russia

South Korea

Japan

Malaysia

Singapore

Brazil

Opportunity Matrix for Global Iron bird test setups in defense

The opportunity matrix helps the readers understand the high opportunity segments in this market.

Expert Opinions on Global Iron bird test setups in defense

Hear from our experts their opinion of the possible analysis for this market.

Conclusions

About Aviation and Defense Market Reports

List of Tables

- Table 1: 10 Year Market Outlook, 2025-2035

- Table 2: Drivers, Impact Analysis, North America

- Table 3: Restraints, Impact Analysis, North America

- Table 4: Challenges, Impact Analysis, North America

- Table 5: Drivers, Impact Analysis, Europe

- Table 6: Restraints, Impact Analysis, Europe

- Table 7: Challenges, Impact Analysis, Europe

- Table 8: Drivers, Impact Analysis, Middle East

- Table 9: Restraints, Impact Analysis, Middle East

- Table 10: Challenges, Impact Analysis, Middle East

- Table 11: Drivers, Impact Analysis, APAC

- Table 12: Restraints, Impact Analysis, APAC

- Table 13: Challenges, Impact Analysis, APAC

- Table 14: Drivers, Impact Analysis, South America

- Table 15: Restraints, Impact Analysis, South America

- Table 16: Challenges, Impact Analysis, South America

- Table 17: Scenario Analysis, Scenario 1, By Region, 2025-2035

- Table 18: Scenario Analysis, Scenario 1, By Test, 2025-2035

- Table 19: Scenario Analysis, Scenario 1, By Platform, 2025-2035

- Table 20: Scenario Analysis, Scenario 1, By Type, 2025-2035

- Table 21: Scenario Analysis, Scenario 2, By Region, 2025-2035

- Table 22: Scenario Analysis, Scenario 2, By Test, 2025-2035

- Table 23: Scenario Analysis, Scenario 2, By Platform, 2025-2035

- Table 24: Scenario Analysis, Scenario 2, By Type, 2025-2035

List of Figures

- Figure 1: Global Iron Bird Test Setups Market Forecast, 2025-2035

- Figure 2: Global Iron Bird Test Setups Market Forecast, By Region, 2025-2035

- Figure 3: Global Iron Bird Test Setups Market Forecast, By Test, 2025-2035

- Figure 4: Global Iron Bird Test Setups Market Forecast, By Platform, 2025-2035

- Figure 5: Global Iron Bird Test Setups Market Forecast, By Type, 2025-2035

- Figure 6: North America, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 7: Europe, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 8: Middle East, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 9: APAC, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 10: South America, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 11: United States, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 12: United States, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 13: Canada, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 14: Canada, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 15: Italy, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 16: Italy, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 17: France, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 18: France, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 19: Germany, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 20: Germany, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 21: Netherlands, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 22: Netherlands, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 23: Belgium, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 24: Belgium, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 25: Spain, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 26: Spain, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 27: Sweden, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 28: Sweden, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 29: Brazil, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 30: Brazil, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 31: Australia, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 32: Australia, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 33: India, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 34: India, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 35: China, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 36: China, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 37: Saudi Arabia, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 38: Saudi Arabia, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 39: South Korea, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 40: South Korea, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 41: Japan, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 42: Japan, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 43: Malaysia, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 44: Malaysia, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 45: Singapore, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 46: Singapore, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 47: United Kingdom, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 48: United Kingdom, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 49: Opportunity Analysis, Iron Bird Test Setups Market, By Region (Cumulative Market), 2025-2035

- Figure 50: Opportunity Analysis, Iron Bird Test Setups Market, By Region (CAGR), 2025-2035

- Figure 51: Opportunity Analysis, Iron Bird Test Setups Market, By Test (Cumulative Market), 2025-2035

- Figure 52: Opportunity Analysis, Iron Bird Test Setups Market, By Test (CAGR), 2025-2035

- Figure 53: Opportunity Analysis, Iron Bird Test Setups Market, By Platform (Cumulative Market), 2025-2035

- Figure 54: Opportunity Analysis, Iron Bird Test Setups Market, By Platform (CAGR), 2025-2035

- Figure 55: Opportunity Analysis, Iron Bird Test Setups Market, By Type (Cumulative Market), 2025-2035

- Figure 56: Opportunity Analysis, Iron Bird Test Setups Market, By Type (CAGR), 2025-2035

- Figure 57: Scenario Analysis, Iron Bird Test Setups Market, Cumulative Market, 2025-2035

- Figure 58: Scenario Analysis, Iron Bird Test Setups Market, Global Market, 2025-2035

- Figure 59: Scenario 1, Iron Bird Test Setups Market, Total Market, 2025-2035

- Figure 60: Scenario 1, Iron Bird Test Setups Market, By Region, 2025-2035

- Figure 61: Scenario 1, Iron Bird Test Setups Market, By Test, 2025-2035

- Figure 62: Scenario 1, Iron Bird Test Setups Market, By Platform, 2025-2035

- Figure 63: Scenario 1, Iron Bird Test Setups Market, By Type, 2025-2035

- Figure 64: Scenario 2, Iron Bird Test Setups Market, Total Market, 2025-2035

- Figure 65: Scenario 2, Iron Bird Test Setups Market, By Region, 2025-2035

- Figure 66: Scenario 2, Iron Bird Test Setups Market, By Test, 2025-2035

- Figure 67: Scenario 2, Iron Bird Test Setups Market, By Platform, 2025-2035

- Figure 68: Scenario 2, Iron Bird Test Setups Market, By Type, 2025-2035

- Figure 69: Company Benchmark, Iron Bird Test Setups Market, 2025-2035