PUBLISHER: Global Insight Services | PRODUCT CODE: 1585849

PUBLISHER: Global Insight Services | PRODUCT CODE: 1585849

Global Green Hydrogen Projects Database

The "Global Green Hydrogen Projects Database" is a new subscription offering from Global Insight Services that tracks new green hydrogen production projects. Subscribers receive access to updates to the database and a newsletter summarizing key market developments monthly.

This comprehensive, centralized database is designed to track and analyze the rapidly evolving green hydrogen sector. This innovative database serves as a powerful tool for policymakers, businesses, investors, and researchers by providing real-time data, insights, and projections on the global development and deployment of green hydrogen technologies worldwide. Green hydrogen-produced via electrolysis using renewable energy sources-has gained significant traction as a critical component of the global transition to a low-carbon economy. Investments worth billions of dollars have been made public in order to assist the growth of greenfield projects and boost demand. The cost of manufacturing green hydrogen is already being reduced via efforts to scale technologies.

With over 1,600 global facilities, this database aggregates data on green hydrogen projects, production capacity, investment trends, electrolyzer capacity, electrolyzer technology used, funding details, participants, project status, primary energy source, and timelines for efficient hydrogen project planning and analysis across industries. This comprehensive resource enables clients to manage investments, track project developments, and navigate the fast-evolving hydrogen market. This database facilitates better decision-making and enhances strategic planning for all stakeholders by offering a one-stop solution for global green hydrogen intelligence. It highlights key market trends, identifies emerging opportunities, and tracks the pace of technological breakthroughs, providing users with a competitive edge in the evolving energy landscape.

- Production Rate Insights: Details on green hydrogen plant production rates, allowing stakeholders to evaluate efficiency and scalability

- Comprehensive Manufacturer Coverage: Profiles of leading electrolyzer manufacturers across regions and its technologies

- Performance Metrics: In-depth data on capacity, efficiency, funding value, and project costs

- Project Tracking: Data on ongoing and planned green hydrogen projects globally

- Competitive Benchmarking: Comparisons across green hydrogen projects for technology, price, and production capacity

- Technology Advancements: Tracks emerging technologies, such as PEM, Alkaline, and Solid Oxide, to identify trends and innovations

- Geographic Analysis: Regional breakdowns, enabling clients to target specific markets based on hydrogen adoption trends

- Partnership and Collaboration Data: Information on strategic partnerships and collaborations between different stakeholders involved in green hydrogen initiatives

Database Coverage

| Projects | 1,600+ |

| Region | Global |

| Electrolyzer Manufacturers | 80+ |

| Electrolyzer Capacity Range | 0.1 MW to 10+ GW |

| Hydrogen Production Capacity Range | 1 to 300,000+ (Tons per Year) |

| Project Information | Project name, Project location, Project category, Project participants, Plant status, Funding provider, Funding value, Project cost, Type of renewable energy, Electrolyzer manufacturer, Technology, Electrolyzer Capacity, Hydrogen Production Capacity, Hydrogen End-Users, Project Announcement Year, Project Construction Start Year, Project Construction End Year |

| Electrolyzer Technology | Alkaline Water Electrolysis, Proton Exchange Membrane, Solid Oxide Electrolysis Cell, Anion Exchange Membrane, Capillary-fed Electrolysis and Membrane-Free Electrolysis |

| Project Status | Under Construction, Announced, Operational, Planning Phase, Concept, FID, Feasibility Study, DEMO, FEED |

| Hydrogen End-Users | Ammonia, Cement, Chemicals, E-commerce, e-fuels, Electric Vehicles, Energy, Energy Storage, Fertilizer Production, Food Value Chain, Fuel Cells, Heating, Hydrogen Fuelling System, Logistics, Manufacturing, Methanol, Mobility, Refineries, Steel, Synfuels, Telecommunications |

| Key Hydrogen Companies | H2 Energy, orsted, ENGIE, BP, Infinite Green Energy Ltd, Fortescue Future Industries, ScottishPower, Shell Global, Adani Group, Air Products and Chemicals, Inc., CWP Global, Chariot Limited, Hydrogen Solutions AS, Gen2 Energy, Stord Hydrogen, HyCC, Lhyfe, Hive Energy, Orlen Group, NTPC Ltd., JSW Group, Larsen & Toubro Limited |

| Key Electrolyzer Manufacturers | Nel ASA, Siemens, McPhy Energy, ITM Power Plc, Elogen, Green Hydrogen Systems, iGas Energy GmbH, Next Hydrogen, Asahi Kasei, thyssenkrupp, Cummins, Toshiba Corporation, Plug Power, John Cockerill, H2Greem, Sunfire GmbH, Bloom Energy, Air Liquide, H-TEC SYSTEMS, Enapter AG, Greenzo Energy, European Energy A/S, Verdagy, Elcogen, Shuangliang Group, Nordex SE |

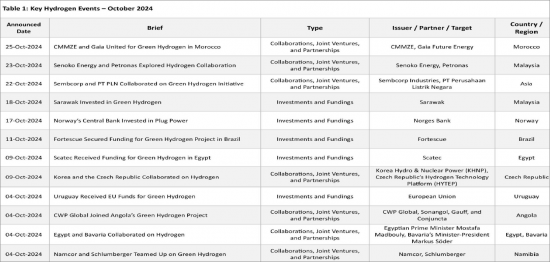

Monthly Newsletter

Subscribers to the service also receive a monthly newsletter summarizing key developments in the sector by:

- Project Announcements & Approvals

- Investments and Fundings

- Collaborations, Joint Ventures, and Partnerships

- Hydrogen Policy

- Electrolyzer Manufacturing

Key Benefits

- 12-Month Subscription: Stay informed year-round with monthly updated newsletters and database access

- Best Price: Most competitive price in the market for full database access

- Unique Offering: Exclusive product features for tailored green hydrogen plant insights

- Discounts: Special discounts on green hydrogen projects database and reports

- 24/7 Analyst Support: Round-the-clock assistance from industry experts

- Consulting Services: Access to expert consulting tailored to client needs

- Research Services: Top-tier research and custom data services provided

Recent Developments

- On October 30, 2024, Avina Clean Hydrogen hosted a groundbreaking ceremony for its new green hydrogen project in Vernon, California. The cutting-edge facility is set to produce up to 4 tons per day (tpd) of compressed green hydrogen through an electrolysis process, powered by renewable electricity to split water into hydrogen and oxygen. Once operational, it will become one of the largest integrated hydrogen production and refueling sites globally. The facility is projected to reduce CO2 emissions by approximately 130,000 tons per year (tpy), contributing to cleaner air and improved environmental conditions.

- On October 28, 2024, Yokogawa Electric Corporation announced that its subsidiary, Yokogawa Italia, has secured a contract to provide an integrated automation and energy control and monitoring system for the Baseload Power Hub-a groundbreaking offshore green hydrogen production and storage pilot plant located within a wind farm. This project is being developed by CrossWind, a joint venture between Shell (80%) and Eneco (20%). The order was placed by Rosetti Marino S.p.A. , an Italian EPCIC contractor.

- On October 23, 2024, Senoko Energy and Gentari, signed a memorandum of understanding (MOU) to explore the feasibility of importing hydrogen gas from Malaysia to Singapore. In the initial phase of the collaboration, Senoko and Gentari aimed to reduce carbon emissions by 18,000 tonnes of carbon dioxide equivalent annually, which was equivalent to removing around 4,000 cars from the roads.

- In October 2024, the Moroccan government and TotalEnergies H2 and its project partners signed a Preliminary Land Reservation Agreement for the Chbika project. This partnership enables TotalEnergies H2, along with Copenhagen Infrastructure Partners (CIP) , and A.P. Moller Capital, to begin pre-FEED (Front-End Engineering Design) studies. The Chbika project aims to develop 1 GW of onshore solar and wind capacity to produce green hydrogen via seawater electrolysis, which will be converted into 200,000 tonnes of green ammonia annually for export to European markets.

- On October 11, Fortescue's $3.6 billion green hydrogen project in Brazil made significant progress with the recent approval of its first phase by the Brazilian government in Ceara. The approval played a crucial role in moving the project forward, which aimed to produce green hydrogen. The initial phase is focused on establishing the required infrastructure and initiating production processes.

SAMPLE VIEW